Severing machine

A technology for cutting machines and knives, applied in sawing equipment, metal sawing equipment, sawing machine devices, etc., can solve the problems of worker discomfort and commodity value decline, and achieve commodity value maintenance, sound elimination, and comfortable use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described below based on the drawings.

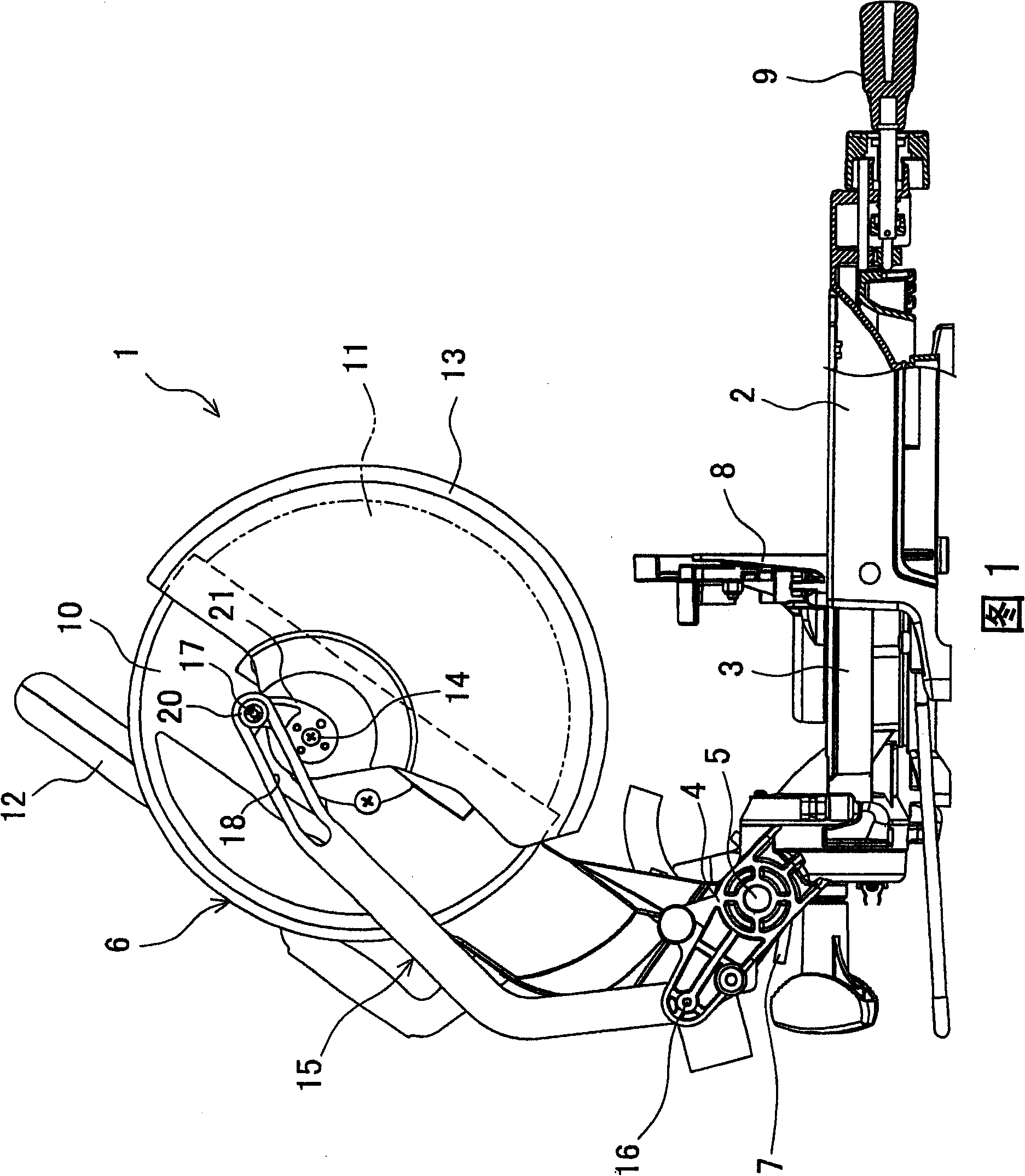

[0018] 1 is an explanatory view of a table-type circular sawing machine as an example of a cutting machine seen from the side. (Left side in the drawing) An arm 4 is erected, and a main body 6 is pivotally mounted to the middle portion of the arm 4 via a support shaft 5 so as to be movable up and down. The main body 6 is loaded toward the top dead center position in FIG. 1 by the torsion spring 7 arranged on the fulcrum 5 part. 8 is a guide fence erected on the base 2 in the left-right direction so as to traverse the turntable 3 , and 9 is an operation lever for rotating and operating the turntable 3 .

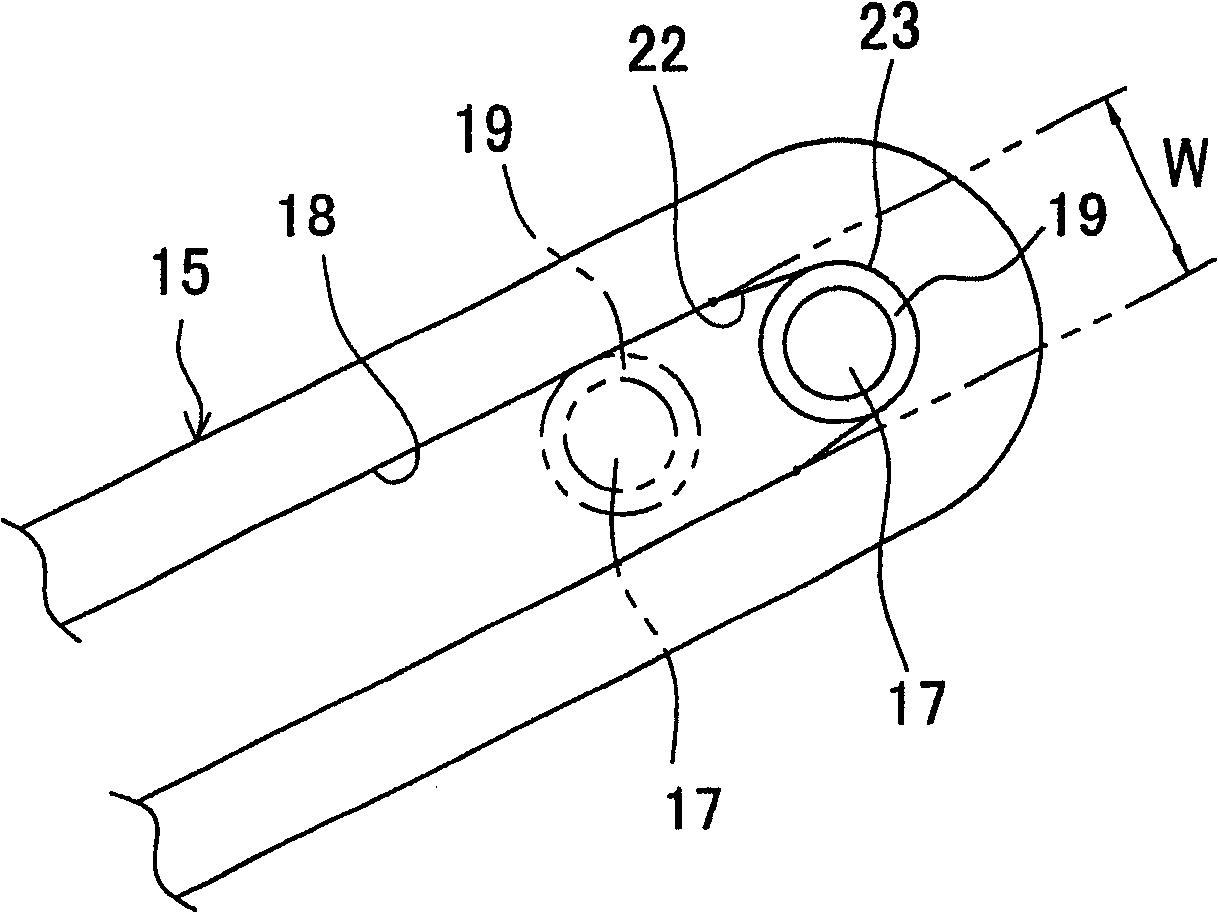

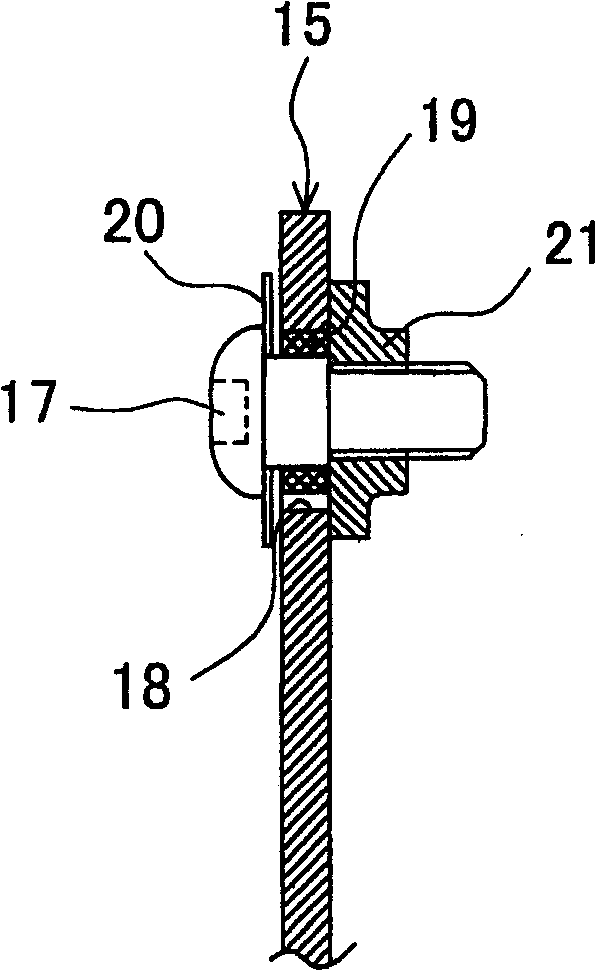

[0019] The main body 6 has: a sawtooth chamber 10 equipped with a motor not shown in the figure; a disc-shaped sawtooth 11 (cutter) which covers approximately half of the obliquely rear side at the top dead center by the sawtooth chamber 10, and is performed by the motor. Rotation; h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com