Compound heat-exchanger

A heat exchanger and composite technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems that liquid plugs and air bubbles cannot coexist, limited effective contact area, limited effective heat dissipation area, etc., and achieve small size, Effect of increased application range and high cooling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

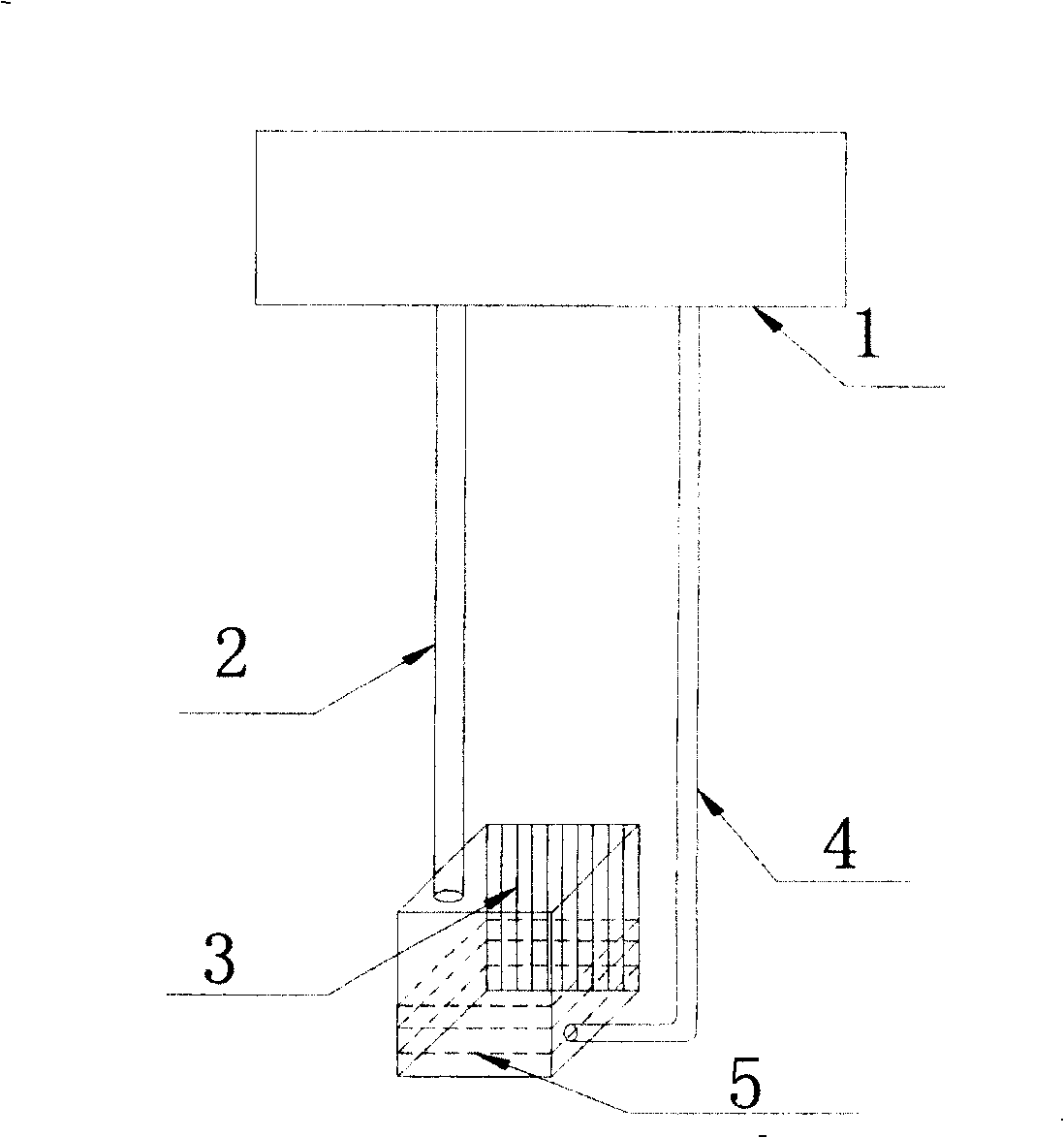

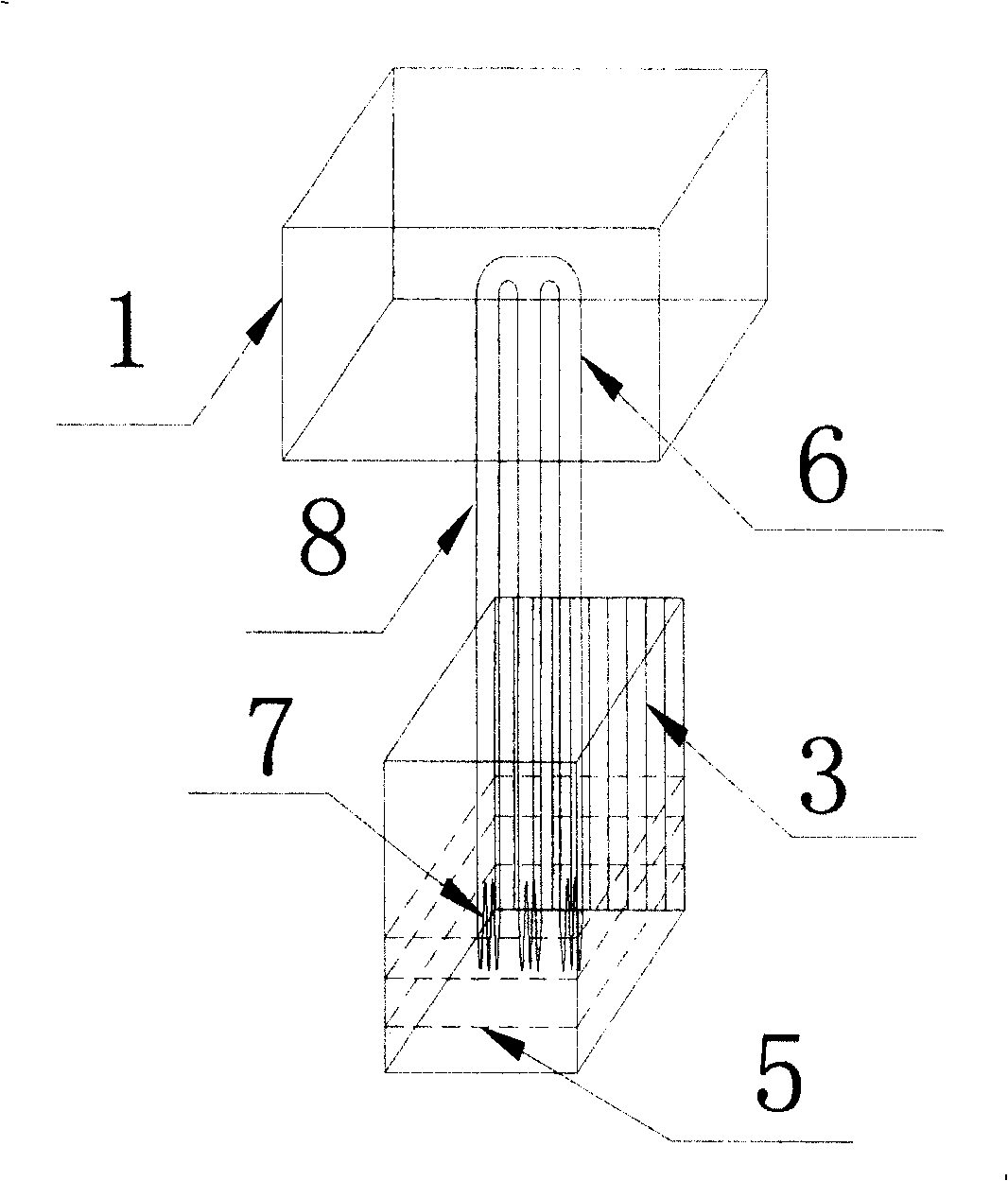

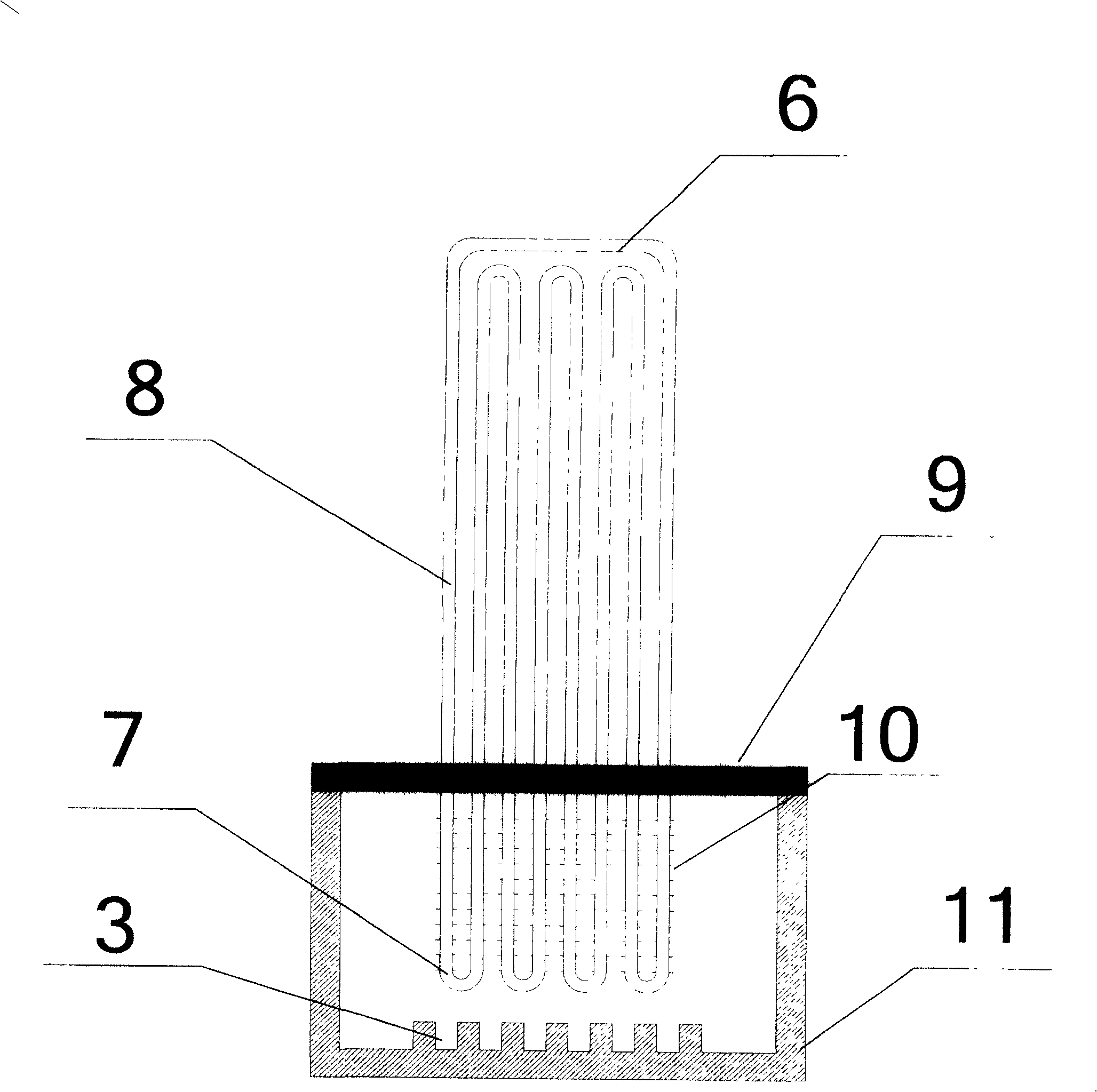

[0042] Such as figure 1 As shown, this mode is a general way of evaporating and cooling microgrooves. Its main working principle is that the wall surface with microgrooves 3 is in direct contact with the heating element, and the liquid working substance 5 in the cavity evaporates on the surface of microgrooves 3. The heat of the heating element is taken out, and then the steam enters the cooling device 1 along the pipeline 2 to condense, the system heat is taken out by the cooling device 1, and the liquid working medium 5 condenses and flows back into the square cavity. The structure of this scheme is simple, but we know that the biggest problem in this scheme is whether the heat can be taken out in time and the working medium can be condensed to ensure circulation. This is the basis for ensuring the normal operation of this mode. Look, it is difficult to ensure its effective operation under high heat generation. The reason is that under high heat generation, the steam cannot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com