Dynamic detecting equipment of pump internal axle axial fitting gap

An axial gap and equipment technology, applied in the field of dynamic testing equipment, can solve the problems of difficulty in guaranteeing repeatability and reliability, and changes in measurement accuracy, and achieve the effects of objective and accurate measurement results, high repeatability, and simple and rapid operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

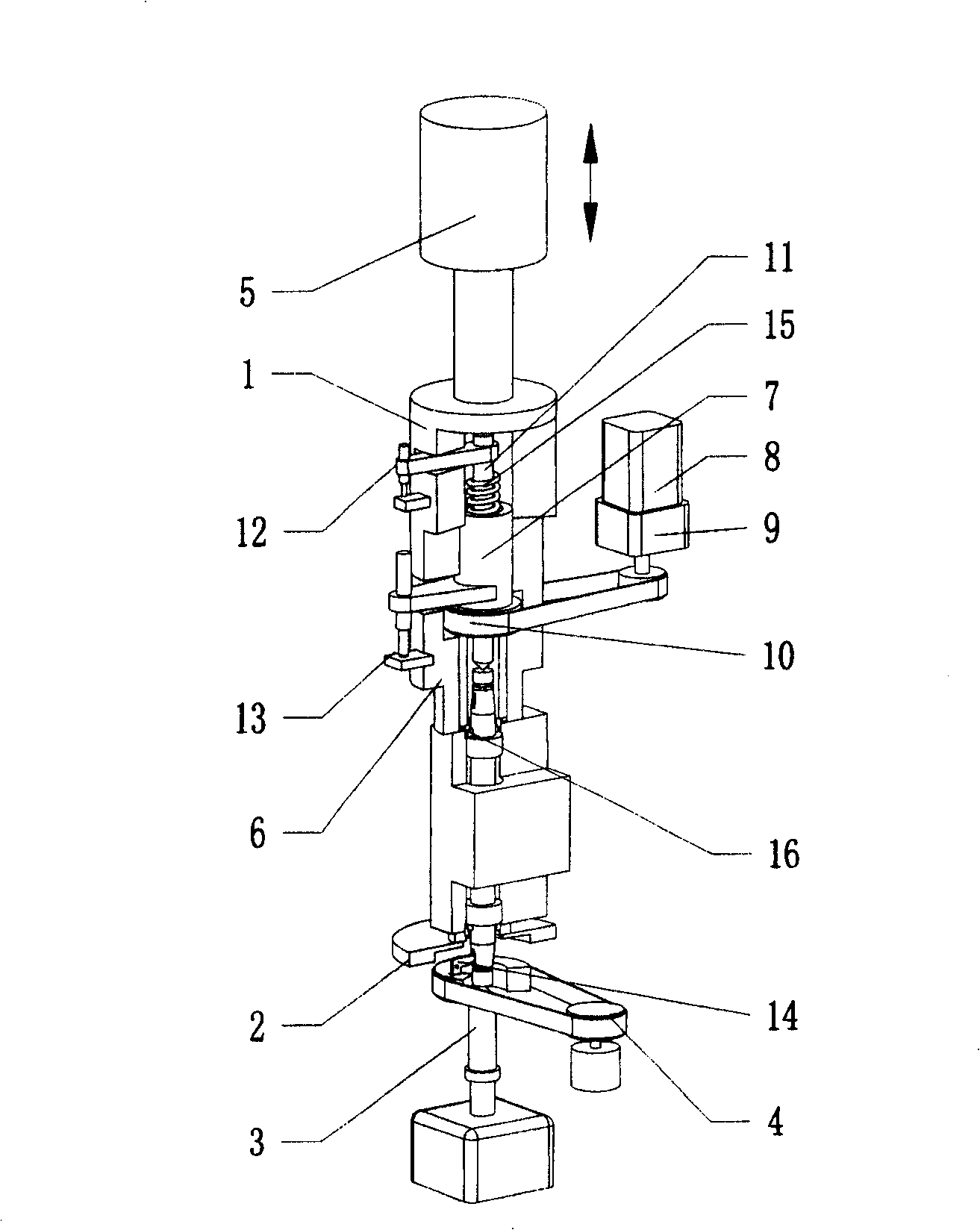

[0011] Such as figure 1 As shown, the present invention includes: an upper pressing mechanism 1, a workpiece positioning mechanism 2, an axial jacking mechanism 3, and an inner shaft rotating mechanism 4, wherein the upper pressing mechanism 1 includes: a cylinder or an oil cylinder 5, a reference pressure block 6, a pressing Insert cylinder block 7, press-in motor 8, reducer 9, synchronous belt 10, push-in rod 11, press-in position sensor 12, height measuring sensor 13. Cylinder or oil cylinder 5 moves up and down close to the end face of the pump body as the reference pressure block 6 of the measurement reference. The side of the reference pressure block 6 is provided with two upper and lower perforated grooves, and the position sensor 12 and the height measurement sensor 13 are pressed into the perforated grooves from the upper and lower sides respectively. and the lower perforation groove; the press-in cylinder block 7 is installed in the center hole of the reference press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com