Ship stern shaft temperature sensor sealing device and mounting method

A temperature sensor and sealing device technology, which is applied to the sealing of engines, parts of thermometers, thermometers, etc., can solve problems such as lubricating oil leakage, pollution of the surrounding environment, temperature signal acquisition data deviation, etc., to prevent lubricating oil leakage, The effect of safe and reliable operation and reduction of economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

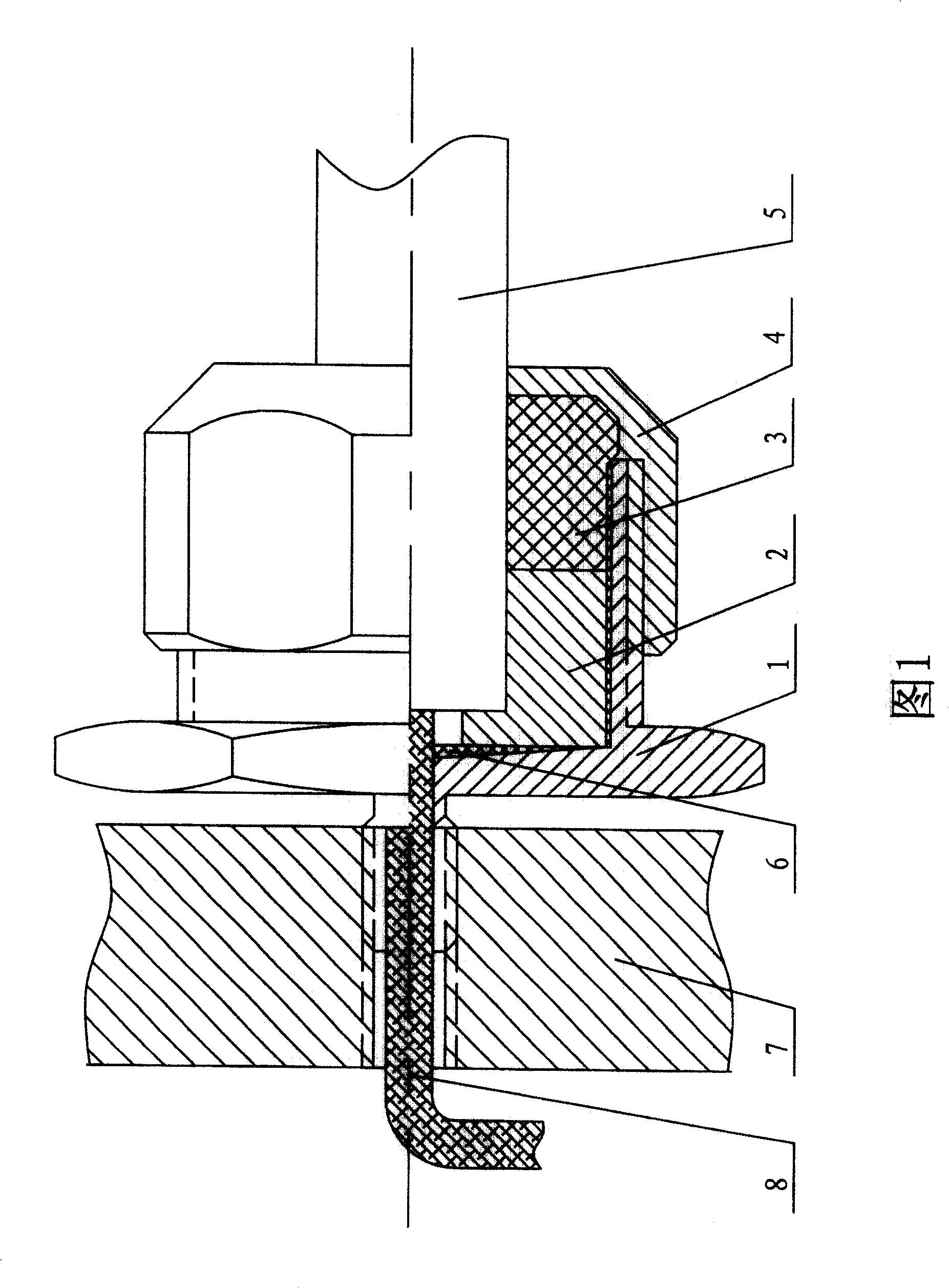

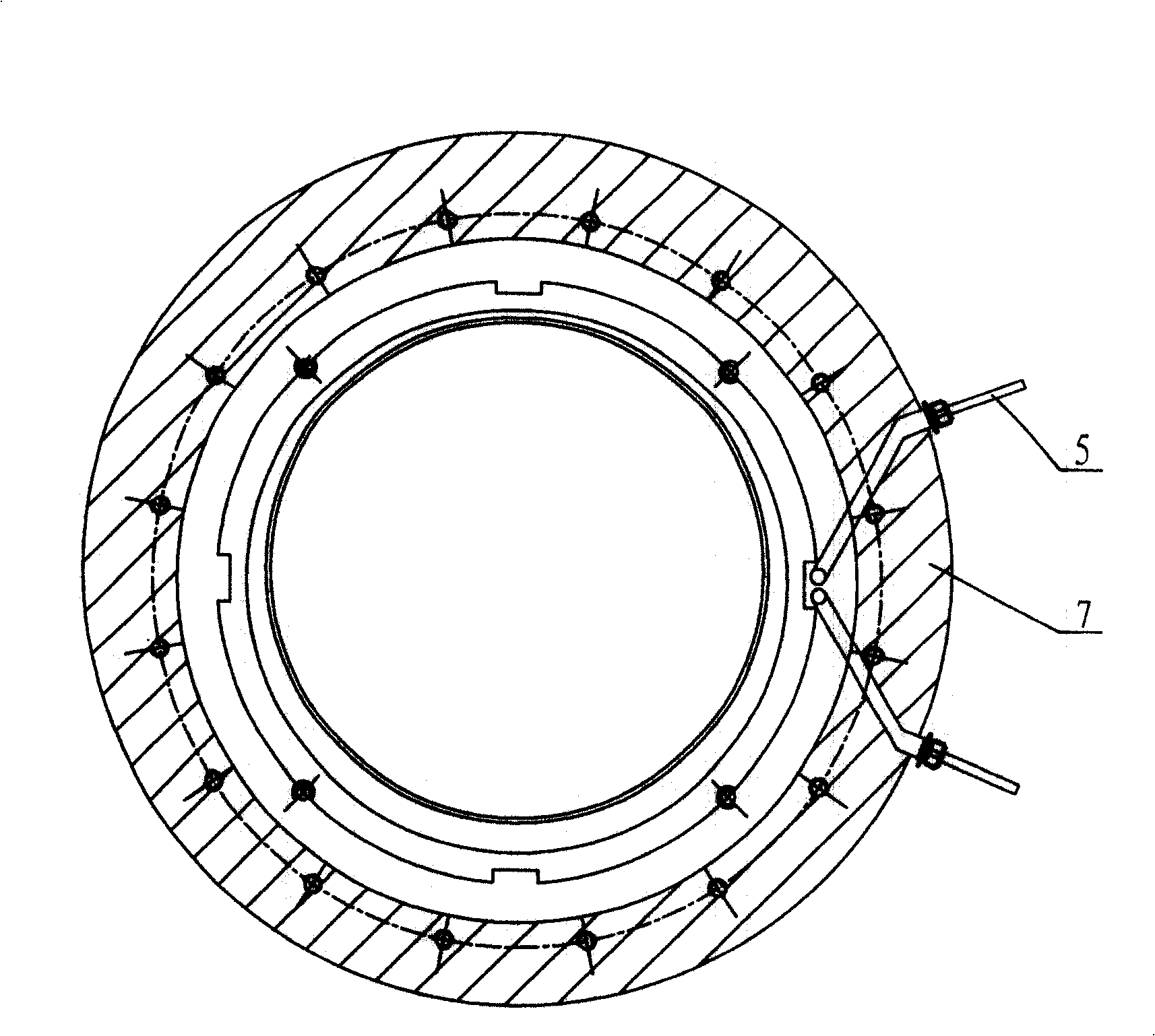

[0018] The sealing device of the ship's stern shaft temperature sensor includes a sensor connector 1, a plika tube connector 2, a sealing locking ring 3, an anti-locking connector 4, and a plika tube 5. The plika tube connector 2, the sealing locking ring 3 (made of rubber) and the anti-locking connector 4 are sequentially set on the plika tube 5, and the plika tube 5 passes through the plika tube connector 2 Install the sealing locking ring 3 in the sensor connector 1, the anti-locking connector 4 is threadedly connected with the tail of the sensor connector 1, tighten the anti-locking connector 4 to connect the Pulica tube connector 2 and the sealing locking ring 3 Tighten and lock, fill the joint 6 of sensor connector 1, plika tube connector 2, and sealing lock ring 3 with sealant to seal, wrap the front of sensor connector 1 with oil-soaked asbestos rope and The mounting holes provided on the stern tube 7 are threaded and tightened. One end of the sensor wire 8 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com