Process and apparatus for producing miniature gum ball centers using underwater pellectizer

A pelletizer, miniature technology, applied in the application, chewing gum, confectionery industry, etc., can solve the problems of high cost, limited provision of spherical shape, sticky surface, etc., to achieve the effect of low floor space and reduced product aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] The test of embodiment 1 and embodiment 2

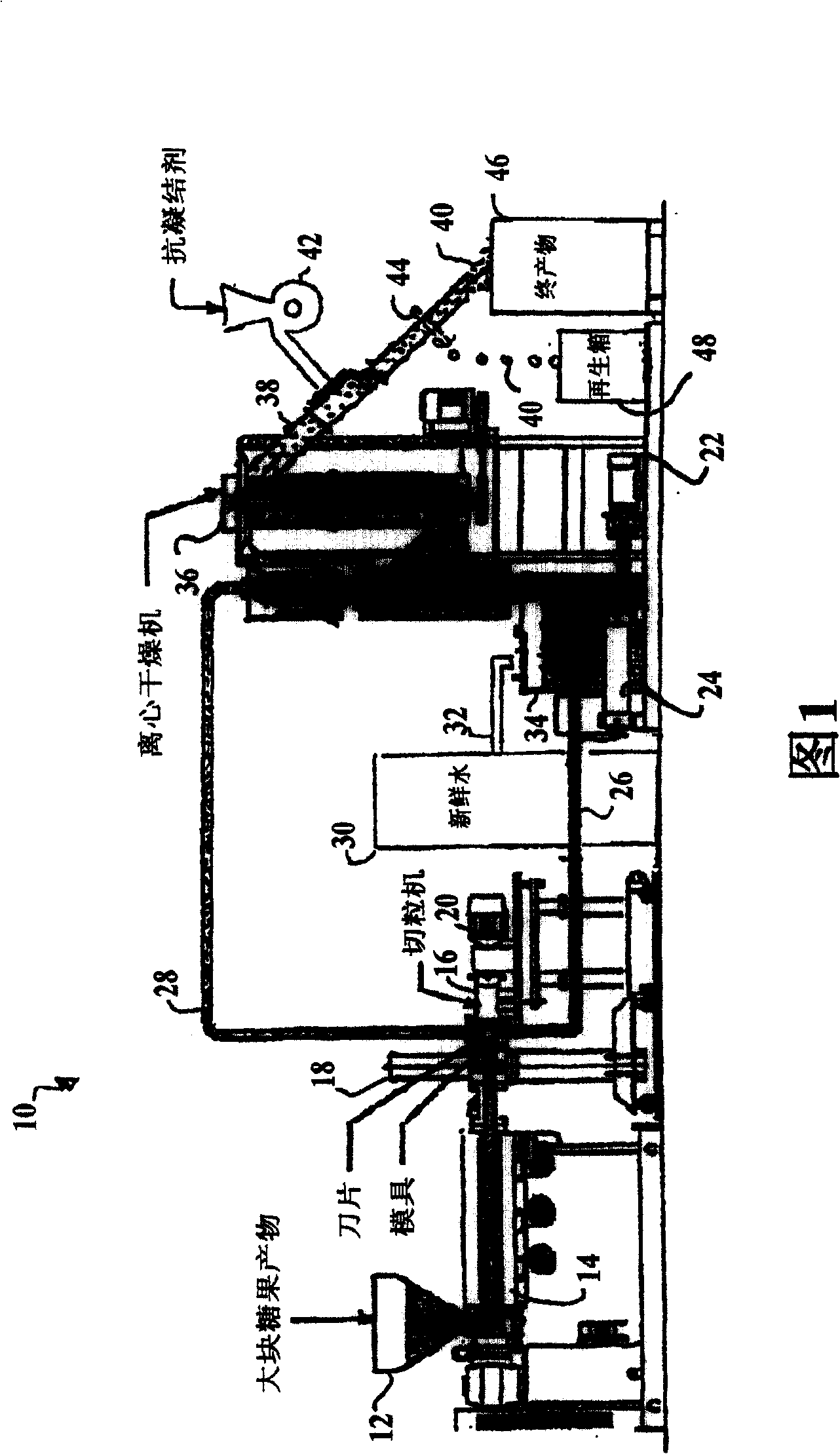

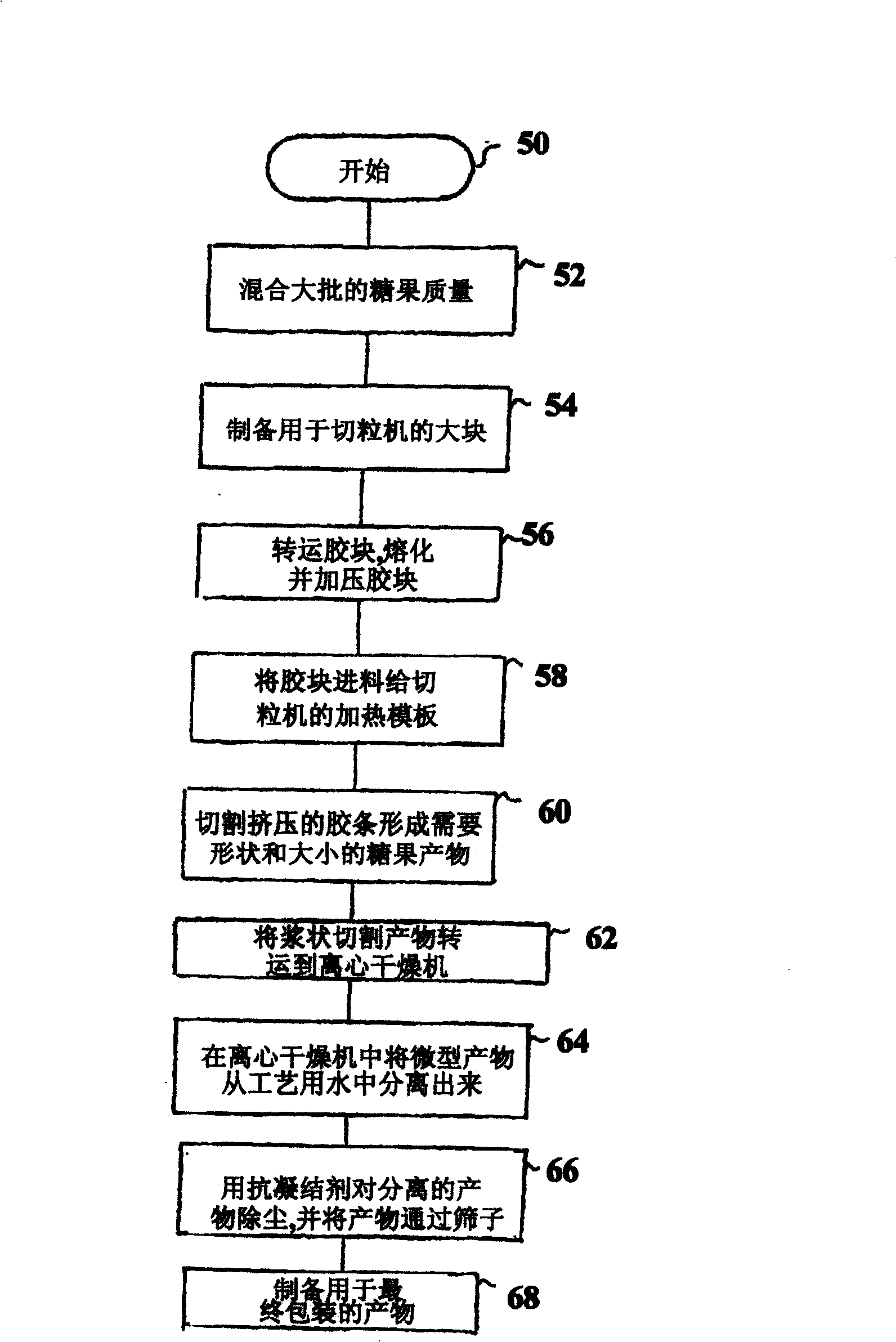

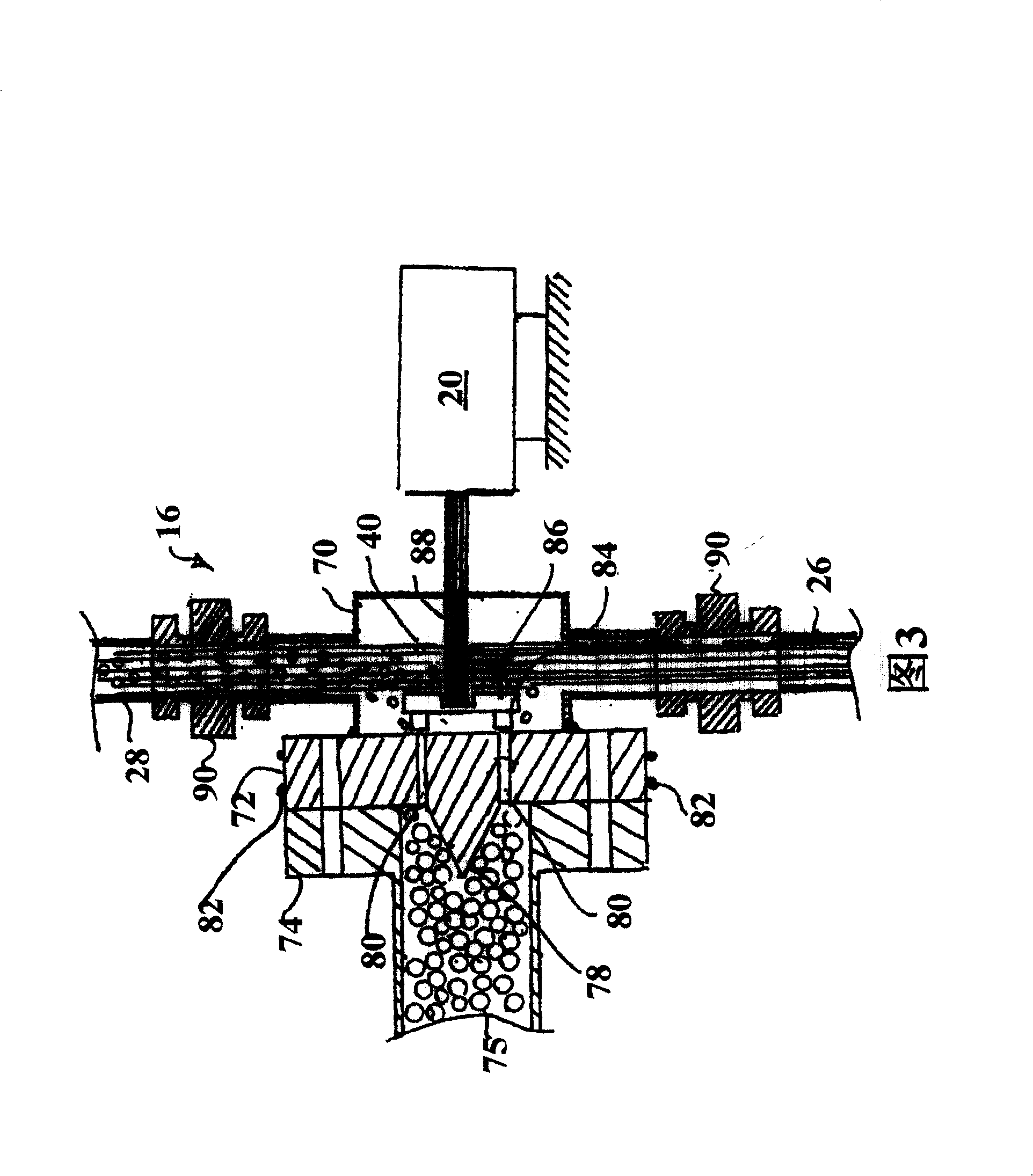

[0080] Example 1 and Example 2 were initially mixed to form pellets. Articles of these shapes are fed from a vibratory feeder to a pressurized single-screw extruder that melts and forces large clumps through a temperature-controlled pelletizer die orifice. After exiting these die holes, the glue is cut into miniature products. Cutting takes place in a cutting chamber filled with water, and the micro-products are immediately quenched in circulating water. As mentioned above, the micro-products are dried, dusted and screened.

[0081] A total of 10 operating conditions were tested to obtain and fine-tune the microballs to the desired round shape and weight. The most important operating variables are extrusion speed, die top temperature, and cutting speed. Tables 2 and 3 summarize the main operating parameters along with the obtained microgumball weights and weight standard deviations. The results of trials 1, 2, 4, 5, 6, 7 ...

Embodiment 3

[0089] The test of embodiment 3

[0090] After the operating parameters were more clearly defined, Example 3 was subjected to further testing. The gum components (flavor, sweetener) from Example 3 were added at the end of the gum base mixing step before the bulk material was extruded through the water immersion pelletizer. Table 4 shows the sieve sizes and % retention in the sieves.

[0091] Table 4

[0092] Sieve Size (inches)

[0093] Example 3 had good product consistency, including shape, weight and size. Blade speed, pump speed, and temperature are adjusted several times during the run to maintain target weight. All batches exhibited acceptable processing characteristics and the three batches produced no significant differences in microproducts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com