Process for assistant chemical treatment of oil field sullage rotational flow

A technology for chemical treatment and oilfield sewage, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve problems such as sewage can not be treated in a timely and effective manner, unsuitable for high-concentration sewage, large batch drainage, etc. The effect of hydraulic retention time, realization of airtightness, and improvement of utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

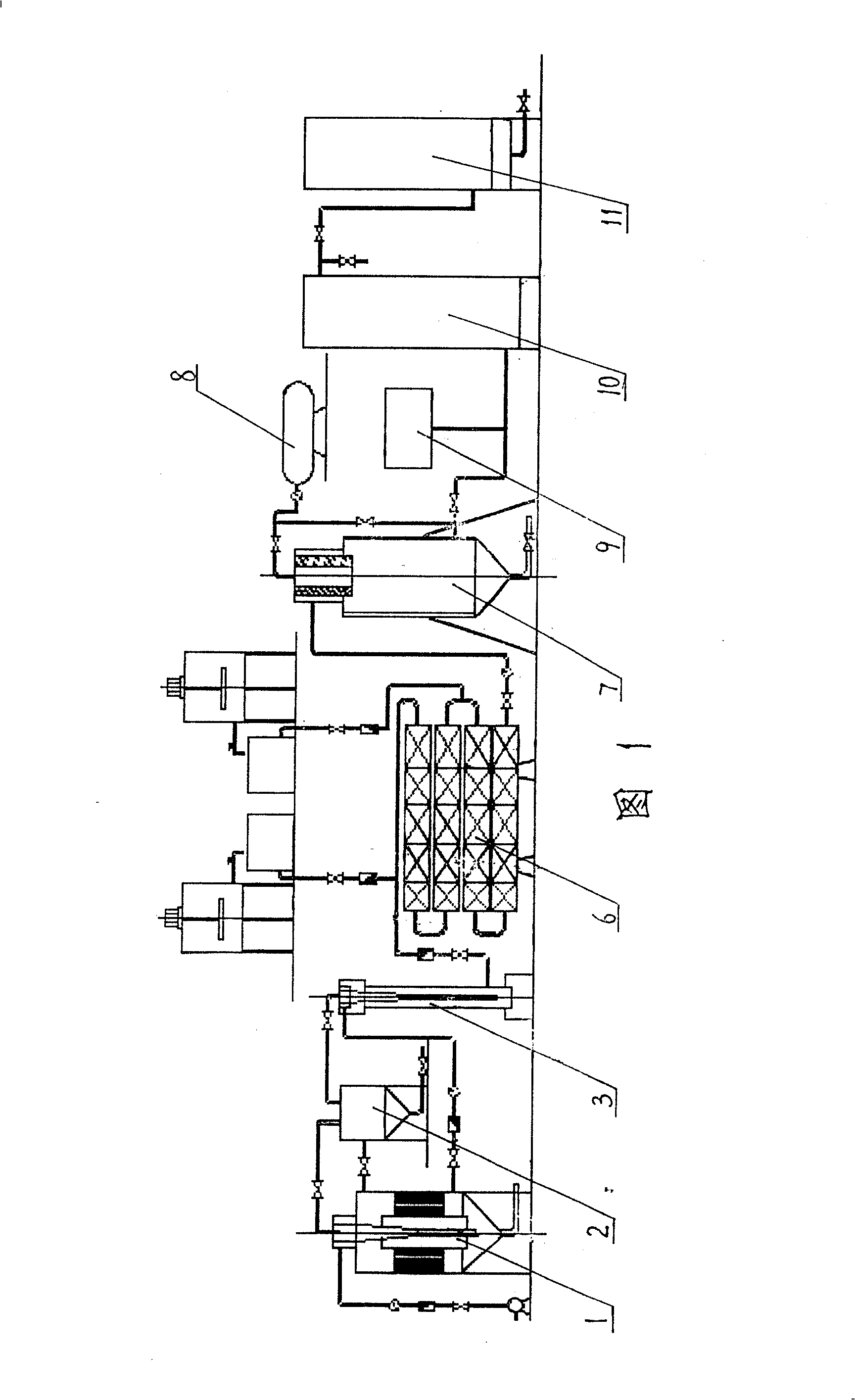

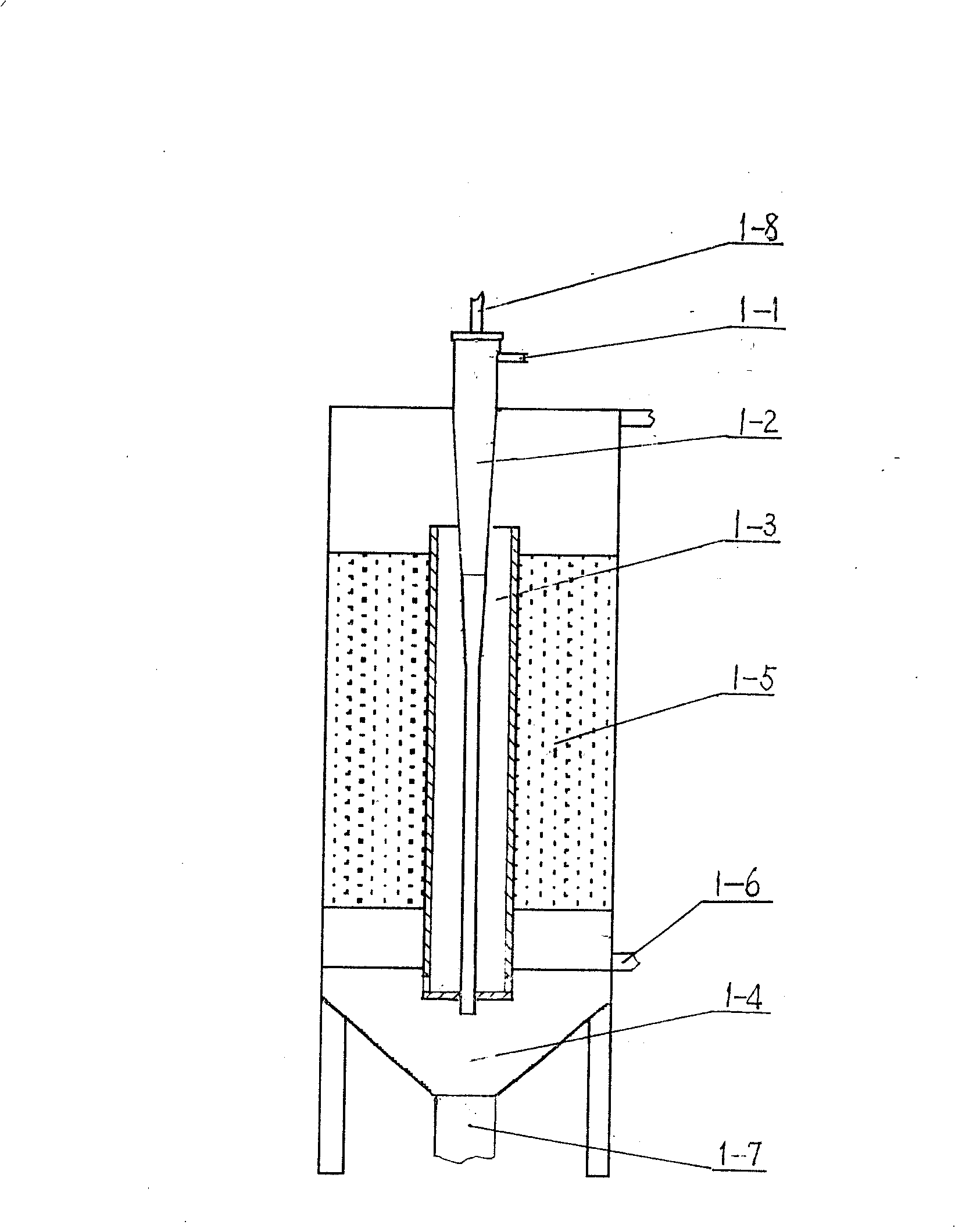

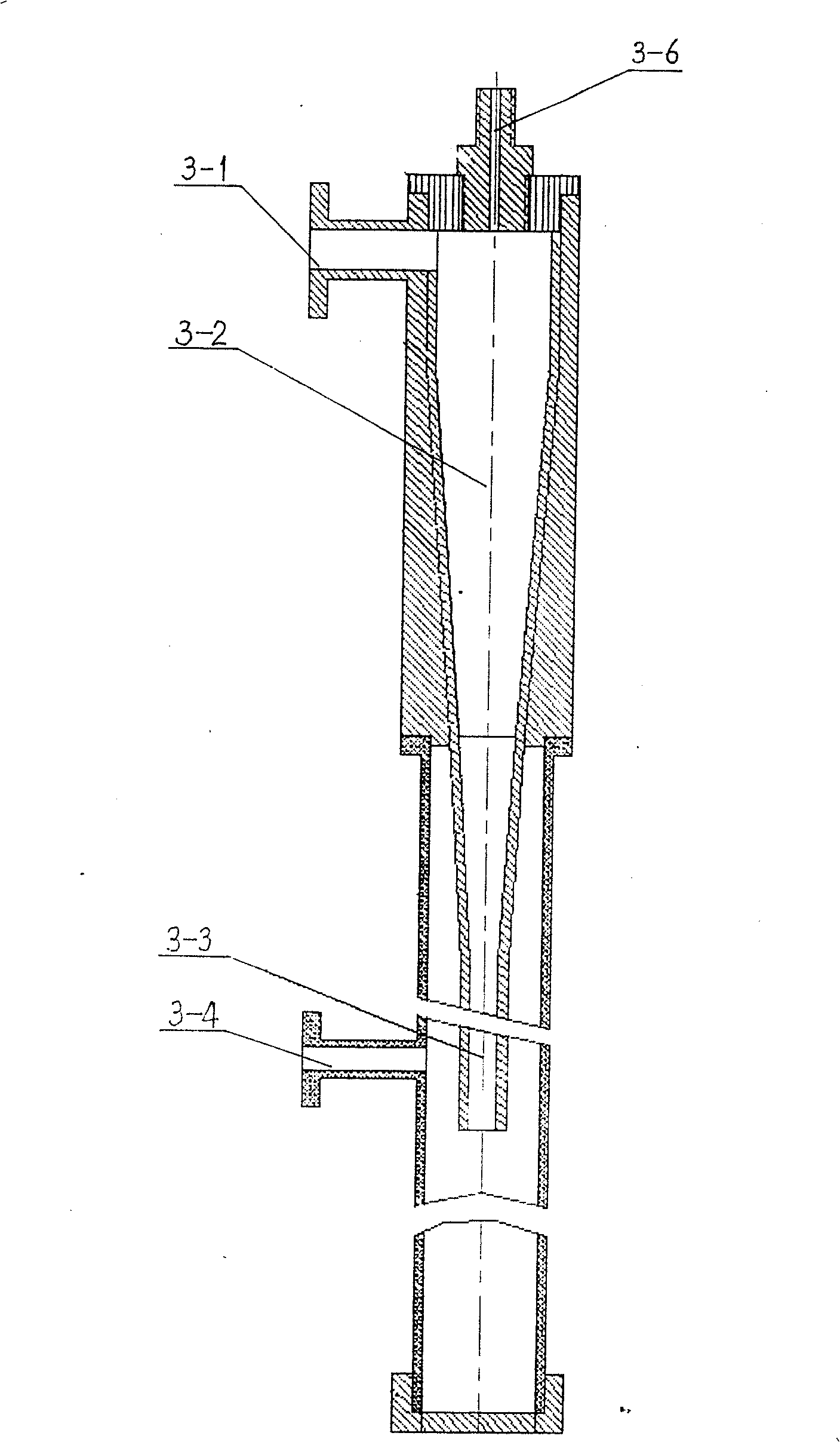

[0016] Figure 1, figure 2 , image 3 , Figure 4 and Figure 5 Shown, the oilfield sewage swirl auxiliary chemical treatment method of the present invention comprises the following processing steps:

[0017] (a) The sewage enters the three-phase separator 1 through the water pump. When the sewage passes through the three-phase separator to the water inlet pipe 1-1, the water flow rotates, and the rotating sewage falls along the solid-liquid cyclone separator 1-2. The separation of liquid and solid particles is realized during this falling process, and the solid particles settle into the solid storage chamber 1-4 at the bottom of the three-phase separator 1, and are discharged from the mud discharge outlet 1-7 arranged at the lower part of the solid storage chamber 1-4 , the liquid part in the sewage rises to the top of the coarse-grained packing chamber 1-5 along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com