Regulating apparatus and regulating method for slit spray nozzle front end

A slit nozzle and adjusting device technology, which is applied to spraying devices, spraying devices, chemical instruments and methods, etc., can solve problems such as a large amount of cleaning liquid, uneven expansion of liquid droplets, and inability to uniformly clean the front end of the nozzle, and achieve effective adjustment, The effect of shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

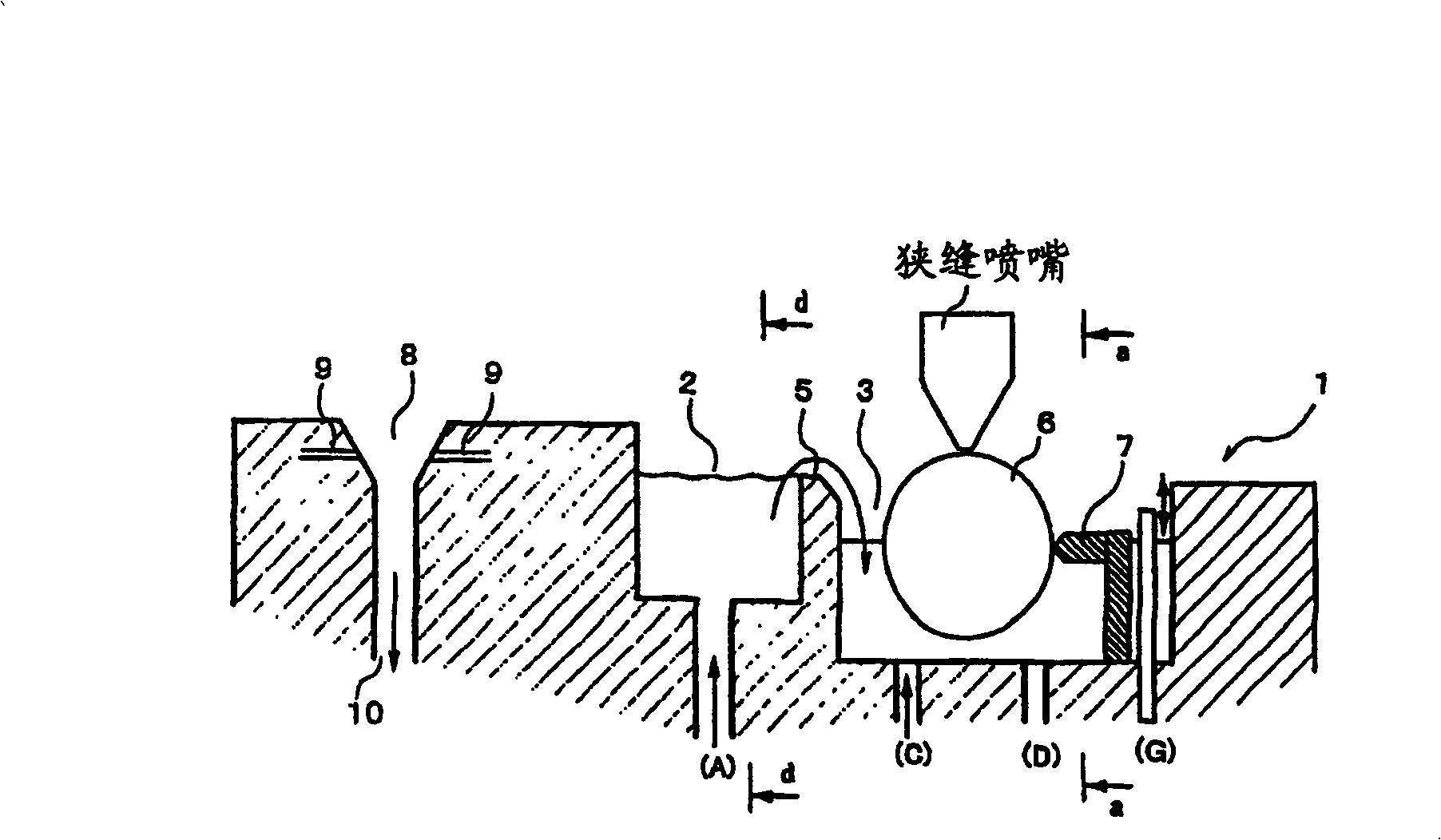

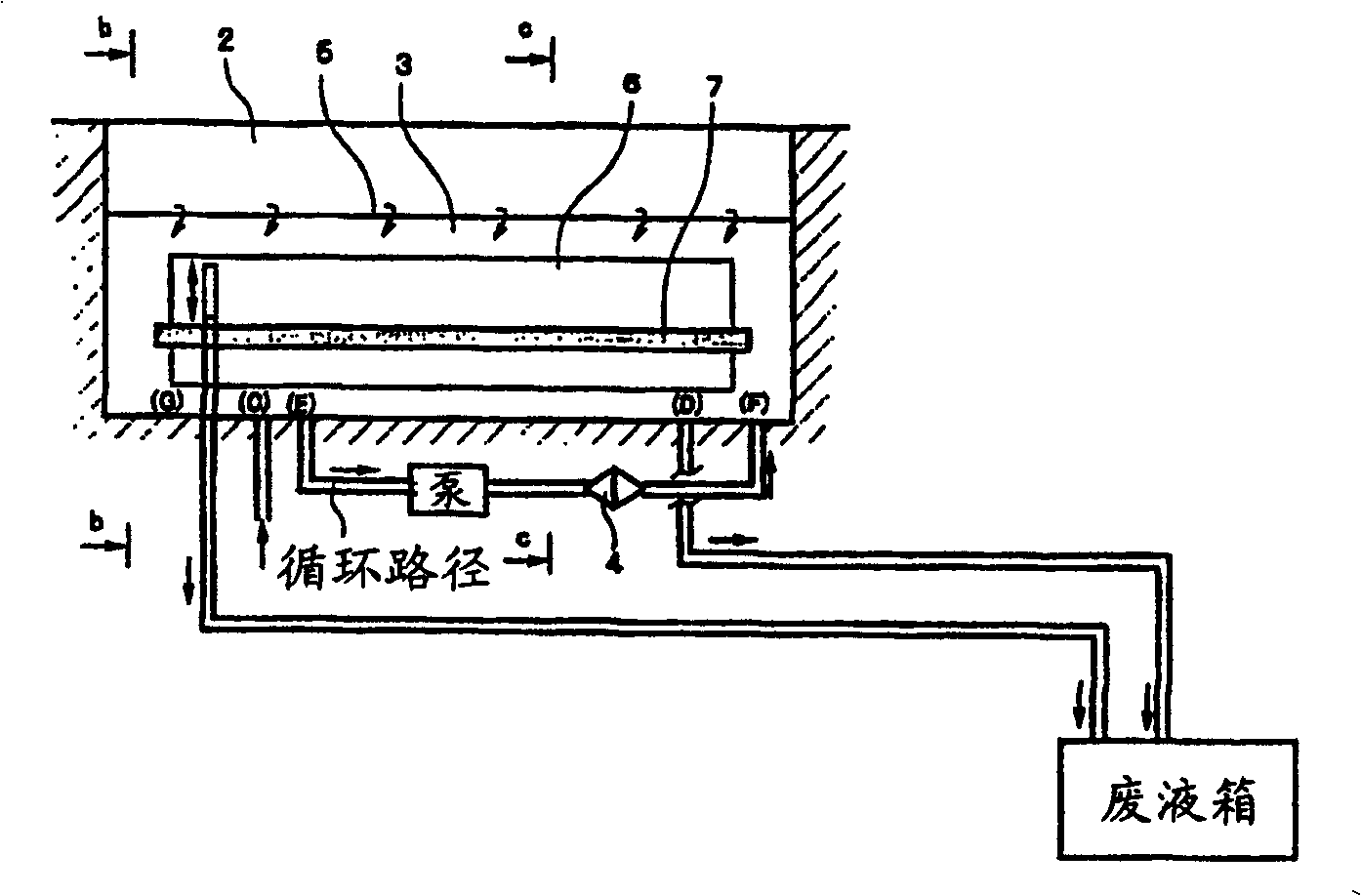

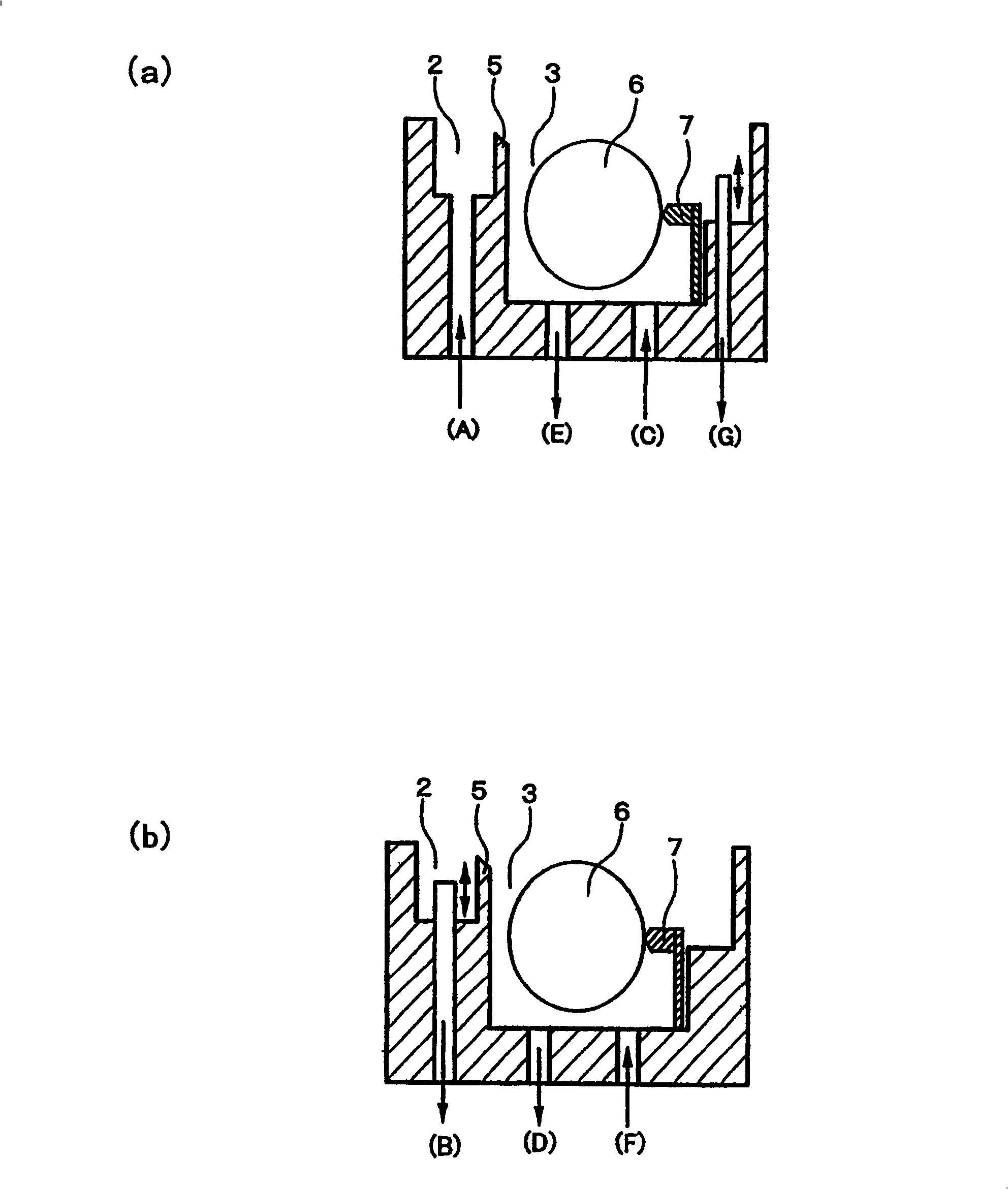

[0041] Embodiments of the present invention will be described below with reference to the accompanying drawings. in, figure 1 is a structural diagram of a slit nozzle front end adjustment device according to the present invention, figure 2 yes figure 1 The piping diagram of the premix section in image 3 (a) and (b) are respectively figure 2 b-b sectional view and c-c sectional view in, Figure 4 yes figure 1 The pipe layout diagram of the cleaning part in the d-d cross-sectional view, Figure 5 (a) is another example of the premixing section, and (b) is a cross-sectional view of e-e in (a).

[0042] Such as figure 1 As shown, an immersion cleaning unit 2 is provided in the middle of the adjustment device 1 at the front end of the slit nozzle, and the bottom surface of the immersion cleaning unit is provided with a supply port (A) for supplying cleaning liquid and a discharge port capable of adjusting the liquid level of the cleaning liquid. (B) (refer toimage 3 )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com