Improved winding-machine for rolled or drawn wire/rod

A technology for coilers and bars, applied in the field of coilers, can solve problems such as obstruction of transportation, irregular coils, wire clogging, etc., and achieve the effect of reducing the risk of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

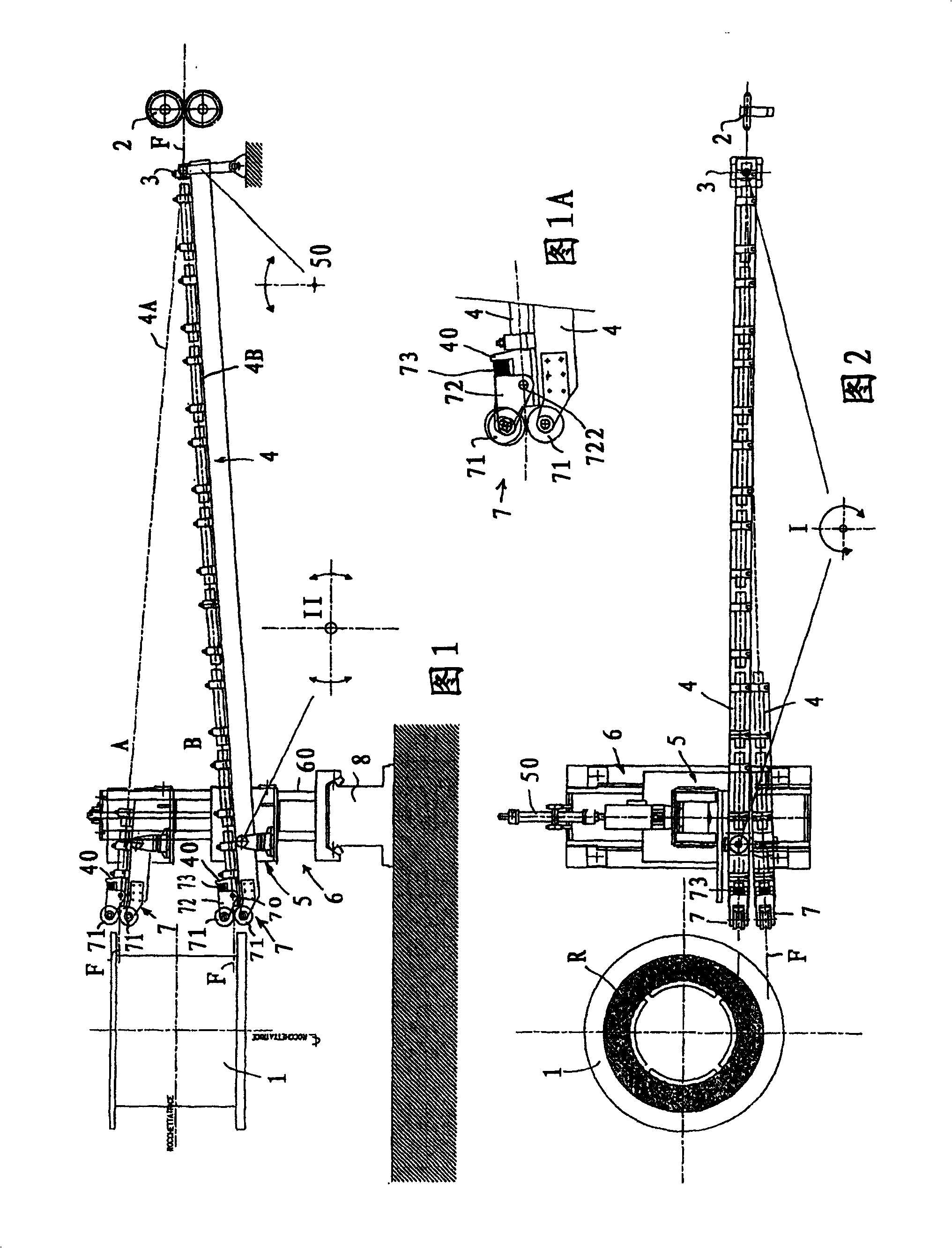

[0037] As disclosed in the above figures, the wire / rod (F) can clearly be seen coming from a prior art rolling mill not represented in the figures (but also from a drawing unit).

[0038] Thereby also upstream the wire / rod cutting means, so that when the coil (R) is complete, the wire / rod can be diverted according to the prior art to another coiler (only one shown), which allows unloading to have been completed roll, which is conveyed to the strapping machine, while another roll is formed.

[0039] Thus schematically, upstream of the individual wire / rod guides (4) there is a feed device, for example with a traction for conveying the wire / rod (F) to the wire / rod guide inlet (3) The device (2), the wire / rod guide inlet (3) is hinged to allow the wire / rod guide to swing back and forth in a vertical plane (4A-4B) to deliver (5-6) helical turns, and with The coiling diameter increases and it oscillates on a horizontal plane (6-8-50) in order to gradually move away from the mandrel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com