A low-flow pulsation two-way gear pump

A bidirectional gear pump, low flow technology, applied in the pump, rotary piston/oscillating piston pump parts, pump components, etc., can solve the problems of low self-lubricating fluid medium, shortening the life of the gear pump, large pump volume, etc. , to reduce flow pulsation and pressure pulsation, reduce noise and impact, and simplify the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

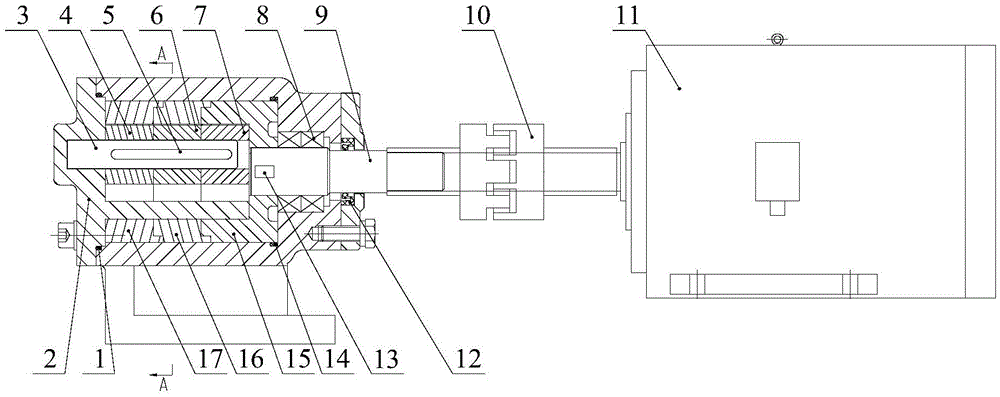

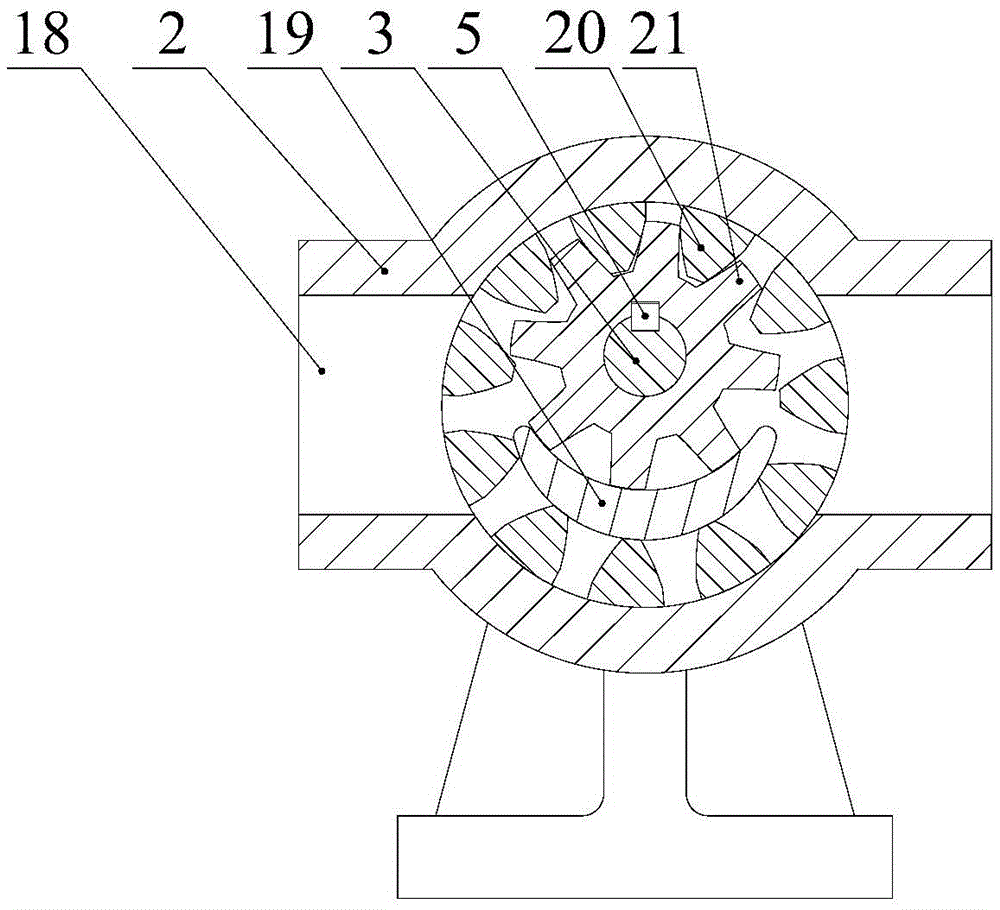

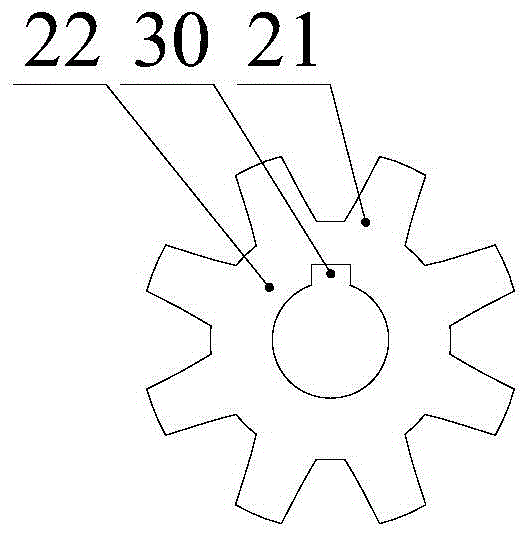

[0051] The low-flow pulsation bidirectional gear pump of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0052] Such as figure 1 , 2 As shown, a low-flow pulsation two-way gear pump includes a pump casing 2, a driving shaft 9 and a driven shaft 3 arranged in the pump casing, and a motor 11. One end of the driving shaft 9 passes through the pump casing 2, and passes through the coupling The device 10 is connected with the motor 11, and the part of the drive shaft extending into the pump casing is installed on the pump casing through a pair of back-to-back bearings 8, and the end face seal of the drive shaft is realized through a lip seal 12.

[0053]The pump casing includes a casing and a front cover and a rear cover arranged on the opposite side of the casing. The front cover and the casing are sealed by the first sealing ring 1, and the end of the first internal gear is connected to the casing by the second sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com