Production device for preventing scratch of pull ring material, and detection method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Such as Figure 8 and Figure 9 As shown, the upper photographing device 4 and the lower photographing device 6 are fixedly installed on the rack 51 through the connecting part, and the two ends of the rack 51 are respectively fixedly connected with a moving rod A54 and a moving rod B55, and the moving rod A54 and the moving rod B55 are slidably mounted on the bracket A2, spanning the whole bracket A2; also include a gear 52 engaged with the rack 51, one end of the gear 52 is connected to the bracket A2, and its input shaft It is driven by a driving device A53, which can be a conventional power device such as an engine or a motor. The length of the rack 51 is determined by the moving speed of the belt-shaped pull-ring material, the width of the belt-shaped pull-ring material, and the angle β between the bracket A2 and the belt-shaped pull-ring material. The driving device of the lower camera 6 is the same as that of the upper camera 4 . In this solution, the upper an...

Embodiment 2

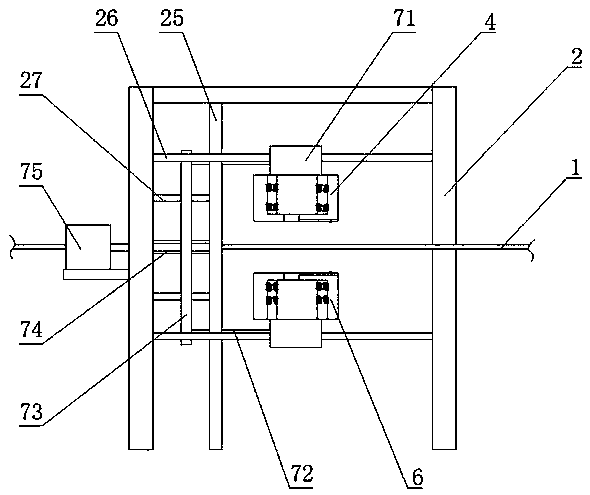

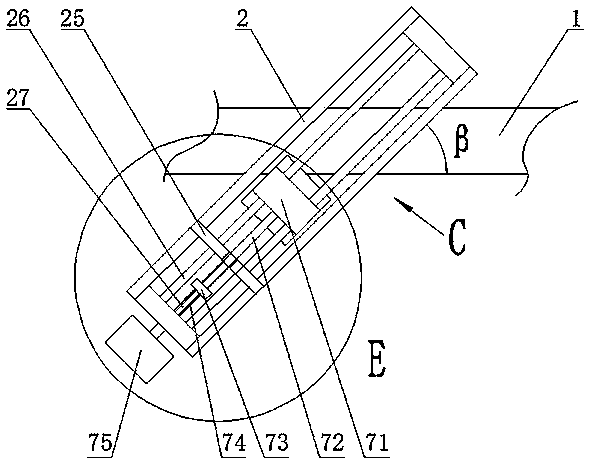

[0067] Such as Figure 10 to Figure 12 As shown, it is another solution of the sliding device 5 of the present application. The upper shooting device 4 is slidably connected to the horizontal sliding bar 26 on the bracket A through the connecting part 71, and can slide along the sliding bar 26. The sliding bar 26 is provided with at least two to ensure that the upper shooting device 4 slides smoothly. balance. A connecting rod 72 is connected to the side of the connecting part 71, and the other end of the connecting rod 72 is fixed on the sliding part 73. The middle part of the sliding part 73 is provided with threads, and its upper and lower ends are respectively provided with sliding holes. On the support A2, a support plate 25 is provided between the left and right side plates, the support plate 25 is vertically arranged, a lead screw 74 is provided between the support plate 25 and the left side plate, and at least two Root slide part slide bar 27. The thread in the midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com