Buffering material-distribution device of cartridge

A technology of distributing device and silo, which is applied in the field of distributing device of silo, can solve the problem of high crushing rate of block materials, and achieve the effect of solving the effect of high crushing rate of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

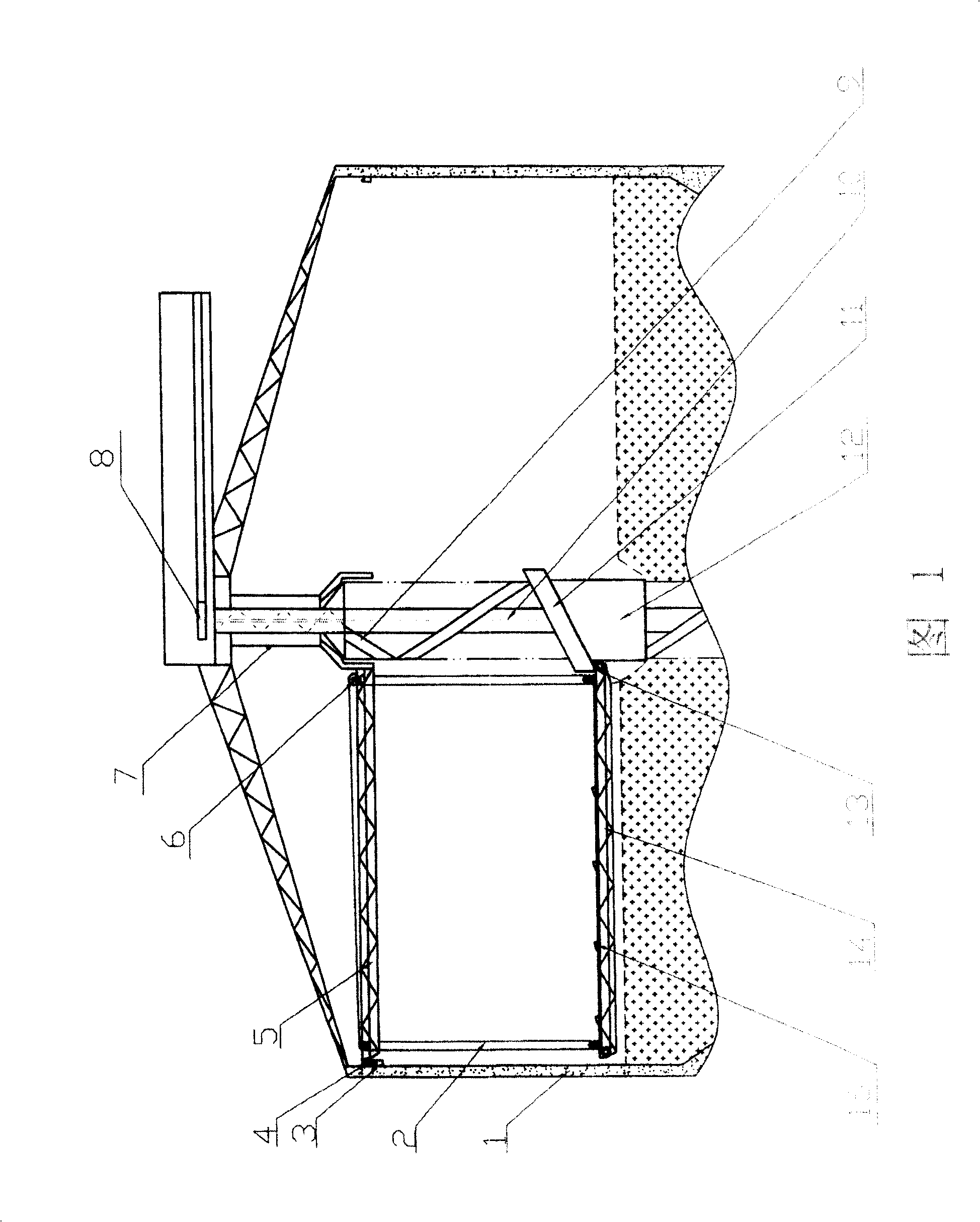

[0018] The structure of the silo buffer distribution device is shown in Figure 1, including a central column 10, a spiral slideway 9, a rotary center 7, a rotary bridge 5, a material distribution rotary bridge 14, a material distribution device 15, a material sealing cylinder 12 and an annular material guide chute 11. The center column 10 is fixed vertically at the center of the silo; the spiral slideway 9 is arranged on the center column 10, the inlet of which communicates with the feed port 8 of the silo, and the outlet directly reaches the bottom of the silo.

[0019] A ring-shaped track 3 is arranged around the upper part of the silo wall 1, and a turning center 7 is arranged in the middle of the silo, which is set on the outside of the central column 10 and the spiral slideway 9; one end of the turning bridge 5 is placed on the ring On the track 3, the other end is fixedly connected with the center of rotation 7, and lies horizontally in the silo. It is driven by the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com