Briquette static cage-drawer-type undamaged drying device and using method

A drying device, non-damage technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problems of reducing briquette flammability, high production cost, low production efficiency, etc., to save manual operation costs, The effect of low equipment manufacturing cost and reduction of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

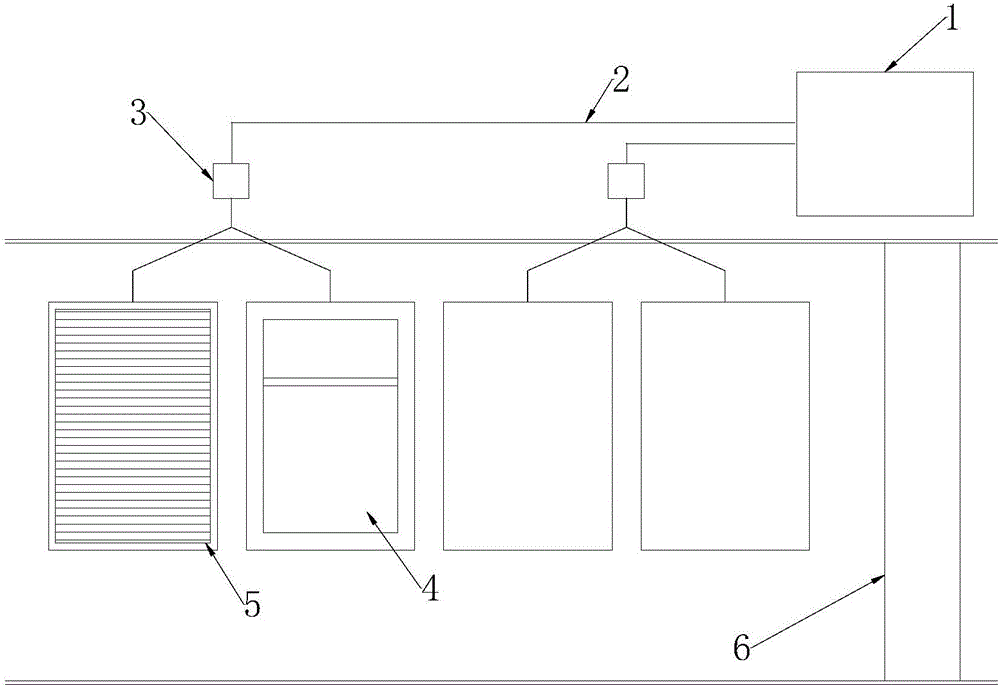

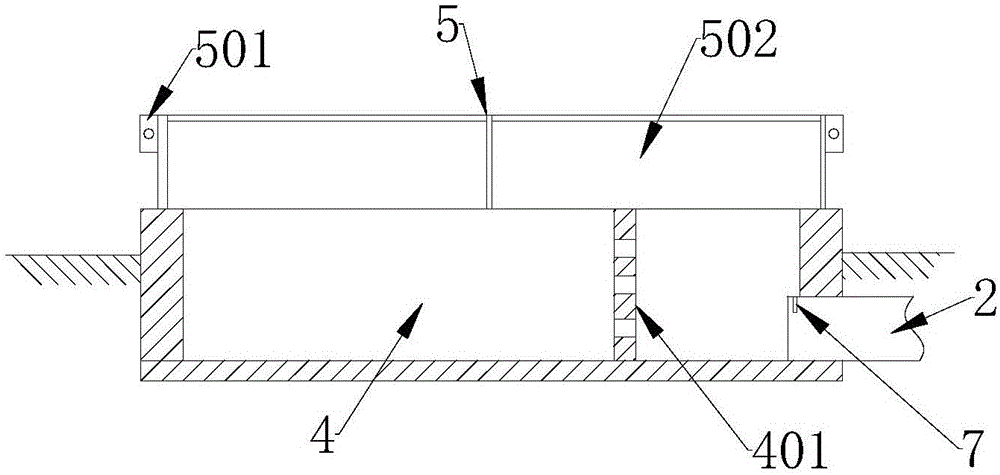

[0025] like figure 1 , 2 As shown, a static cage drawer-type non-damage drying device for briquettes includes a hot blast stove 1 that provides hot air, and the hot blast stove 1 can be coal-fired or gas-fired depending on the situation. The hot blast stove 1 is connected to an open rectangular air distribution pool 4 through a hot blast pipe 2, and an induced draft fan 3 is installed on the hot blast pipe 2. According to the production situation, a hot blast stove 1 can be connected with multiple air distribution pools 4 through the hot air pipe 2, and one induced draft fan 3 can correspond to one or more air distribution pools 4, and the switch of the induced draft fan 3 can be controlled to control the Wind pool 4 working status.

[0026] The air distribution pool 4 adopts a semi-buried brick-concrete s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com