Green brazing method of solar cell si chip al back electrode and cu electrode lead wire

A solar cell, electrode lead technology, applied in circuits, welding equipment, photovoltaic power generation, etc., can solve the problems of producing toxic and harmful gases and smoke, strong flux, corrosiveness, etc., to improve photovoltaic characteristics and avoid corrosive flux. Residual and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0044] Embodiment 1: In this embodiment, pure Sn solder is used. The solder is wire-shaped with a diameter of 1 mm. The solar cell used is a polysilicon solar cell with a thickness of 180 μm and an Al back field thickness of 30 μm.

[0045] In the present embodiment, the method of using pure Sn solder to directly braze solar cell Al back field electrodes and Cu electrode leads is carried out according to the following steps:

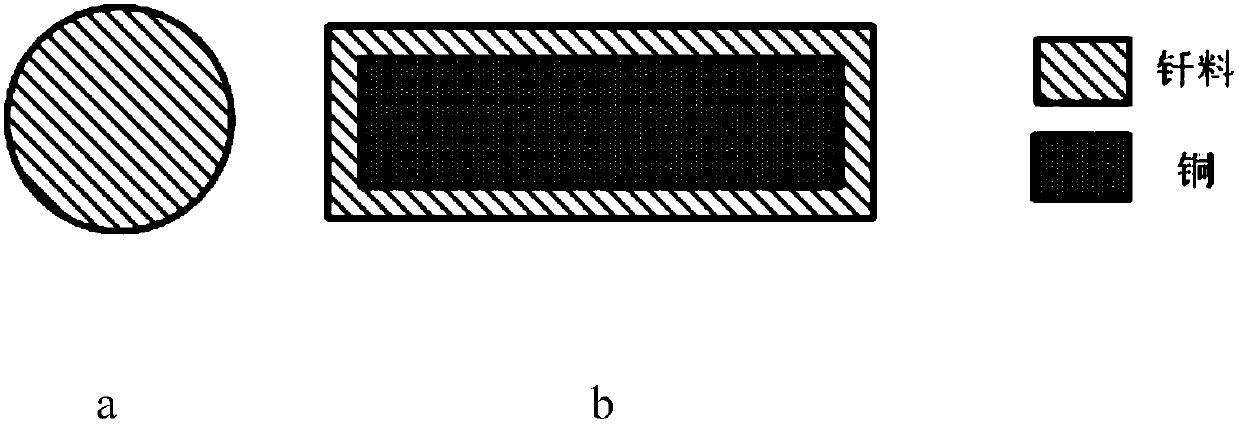

[0046] Step 1. Use an ultrasonic soldering iron to heat up to the brazing temperature. The heating temperature is 260°C. Fill the solder with solder wire. The state diagram of the solder is as follows figure 1 shown

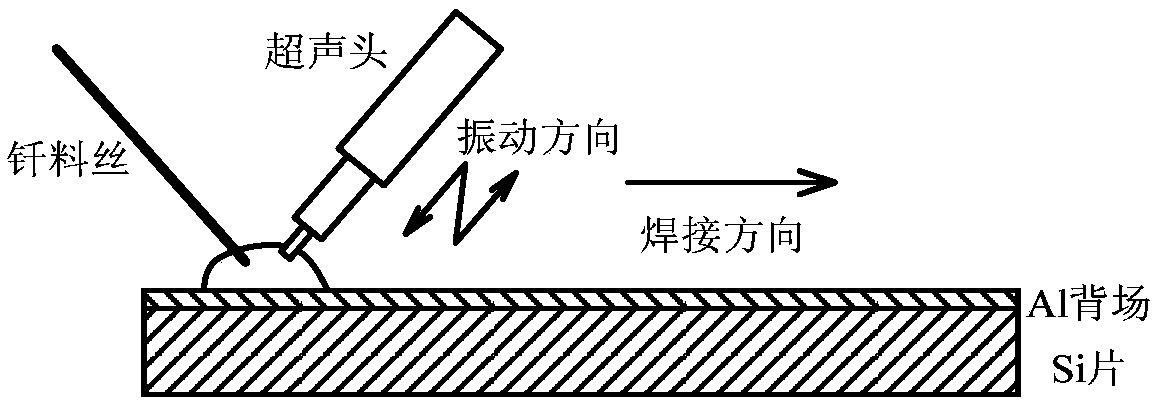

[0047] Step 2. Insert the ultrasonic tool head into the liquid solder, apply ultrasonic waves for 1 second, the frequency of the ultrasonic is 60KHz, and the amplitude range is 1μm, to remove the oxide film on the surface of Al and make the solder fully wet and spread. The brazing schematic diagram is as follows image 3 shown. In order to ...

specific Embodiment approach 2

[0050] Embodiment 2: In this embodiment, SnAgCu solder is used. The solder is in the shape of a wire with a diameter of 0.8mm, and its specific composition is Sn-3.0Ag-0.5Cu (wt.%).

[0051] In the present embodiment, the method of using SnAgCu solder to directly braze the solar cell Al back field and the Cu electrode lead is carried out according to the following steps:

[0052] Step 1. Use an ultrasonic soldering iron to heat up to the brazing temperature. The heating temperature is 240°C. Fill the solder with solder wire. The state diagram of the solder is as follows figure 1 shown.

[0053] Step 2. Insert the ultrasonic tool head into the liquid solder, apply 3s of ultrasound, the frequency of the ultrasound is 20KHz, and the amplitude range is 3μm, to remove the oxide film on the Al surface and make the solder fully wet and spread. The brazing schematic diagram is as follows image 3 shown. In order to reduce the stress level of the joint, discontinuous two strips of so...

specific Embodiment approach 3

[0055] Embodiment 3: In this embodiment, a brazing strip coated with SnBi solder is used.

[0056] In the present embodiment, the method of using the brazing strip coated with SnBi solder to directly solder the Al back field electrode of the solar cell is carried out according to the following steps:

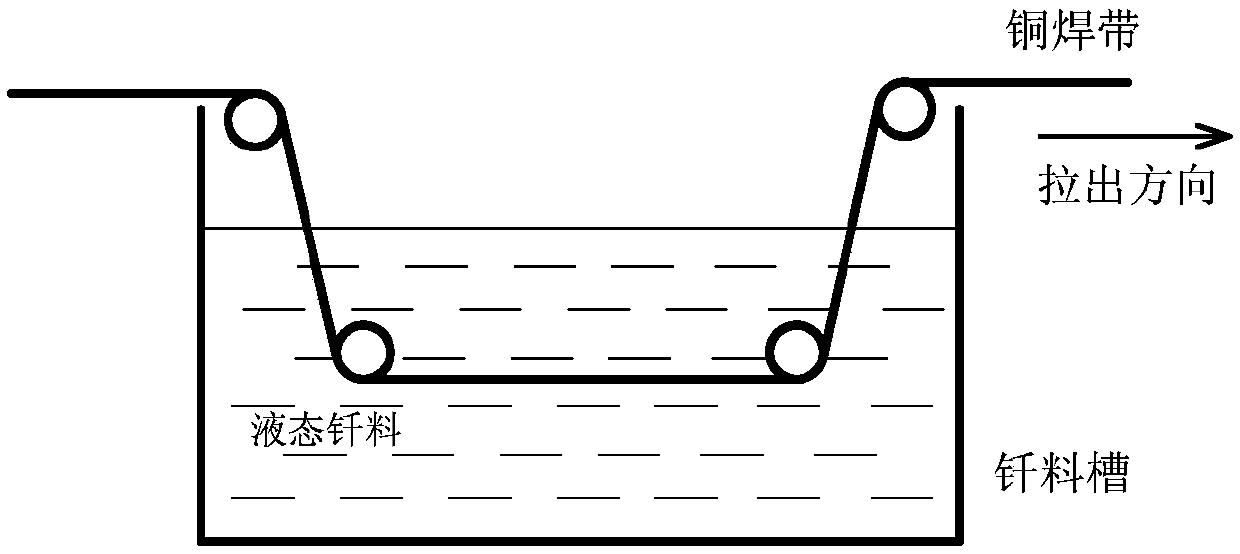

[0057] Step 1, placing Sn-58Bi (wt.%) solder in a solder tank, heating and melting, passing the copper strip continuously through the molten solder to complete the coating of the solder on the surface of the copper strip. The width of the welding strip is 2mm, the thickness of the copper strip is 0.15mm, and the thickness of the coated solder is 0.05mm. The schematic diagram of the state of the solder is shown in figure 1 As shown, the schematic diagram of brazing strip surface coated with solder is as follows figure 2 shown.

[0058] Step 2: Place the two welding strips on the Al back field, and perform infrared heating on the parts to be welded at a heating temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com