Method of producing naphthalene series water reducing agent by refined naphthalene residual oil fraction

A technology of naphthalene-based water reducer and residual oil, which is applied in the field of chemical product production and can solve the problems of shortage of raw materials and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Add 300 grams of refined naphthalene residual oil fractions in a 1000 ml three-necked flask, heat and melt to 120° C. and turn on the stirrer. Then the temperature was raised to 150°C and 330 g of 98% concentrated sulfuric acid was evenly added dropwise, and kept at 150°C-160°C for 2-3 hours under stirring to carry out the sulfonation reaction. After the reaction, cool down to 120°C, add 81ml of water, hydrolyze at 110-120°C for 50 minutes, then add sulfuric acid to make the total acidity around 30%. When the reactant cools down to about 90°C, after dropping 191 grams of 37% formaldehyde within 2 hours, carry out condensation reaction at 95-105°C for 2 hours. When the pH value reaches 7-9, carry out vacuum filtration, concentrate the filtrate to 50%, and spray dry to obtain a brown powder product, or concentrate to a certain concentration to obtain a liquid product.

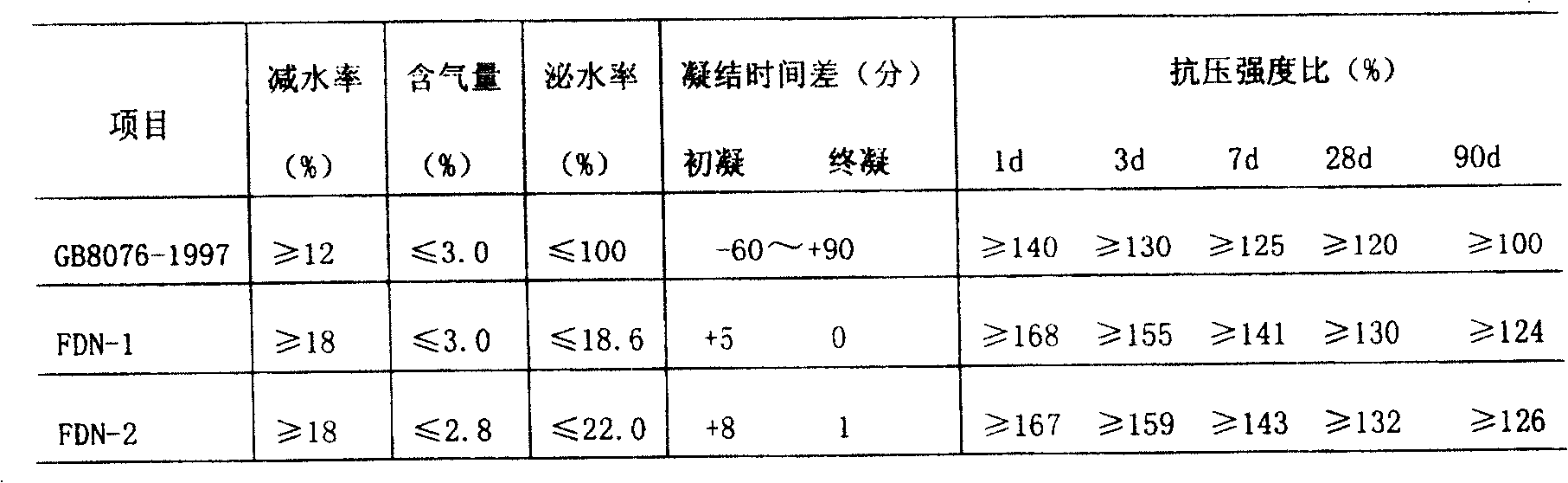

[0012] Table 1 Comparison Table of Performance Parameters of Water Reducer Produced by the Present Inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com