Valve system, especially for improving flow ratio of air inlet valve

A flow ratio, internal combustion engine technology, applied in the direction of internal combustion piston engine, charging system, swing spool valve, etc., can solve the problem of concentricity of the plastic intake pipe, and achieve the effect of light weight, reducing angle error and reducing noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

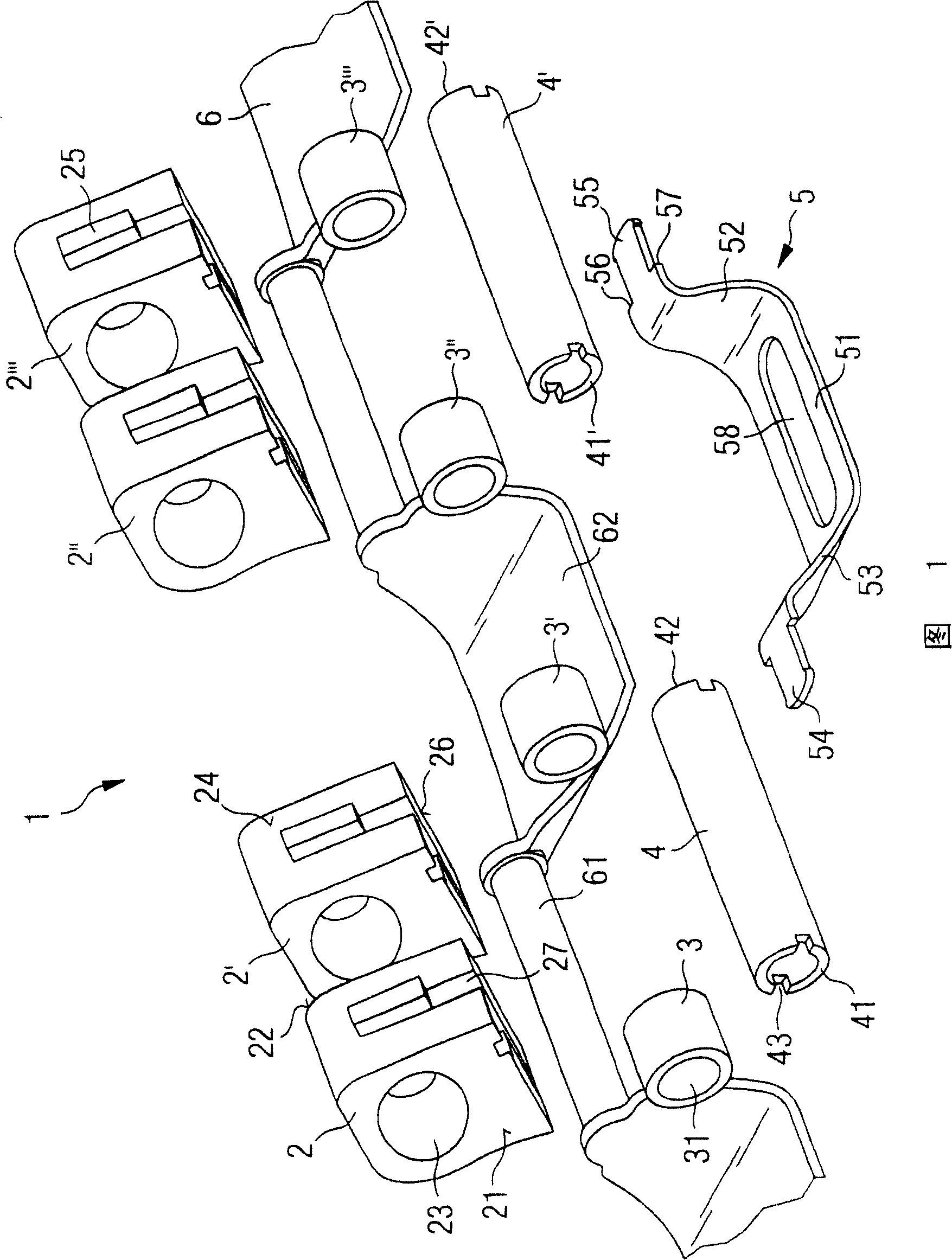

[0017] FIG. 1 shows an exploded view of a valve system 1 according to the invention with four support parts 2, 2', 2", 2"', four bearing bushings 3, 3', 3", 3". ', two hollow shafts 4, 4', a valve 5 and an elastic housing 6 (elastic material). For example, four valves 5 and a corresponding number of other components 2 - 4 and 6 are required for a 4-cylinder engine.

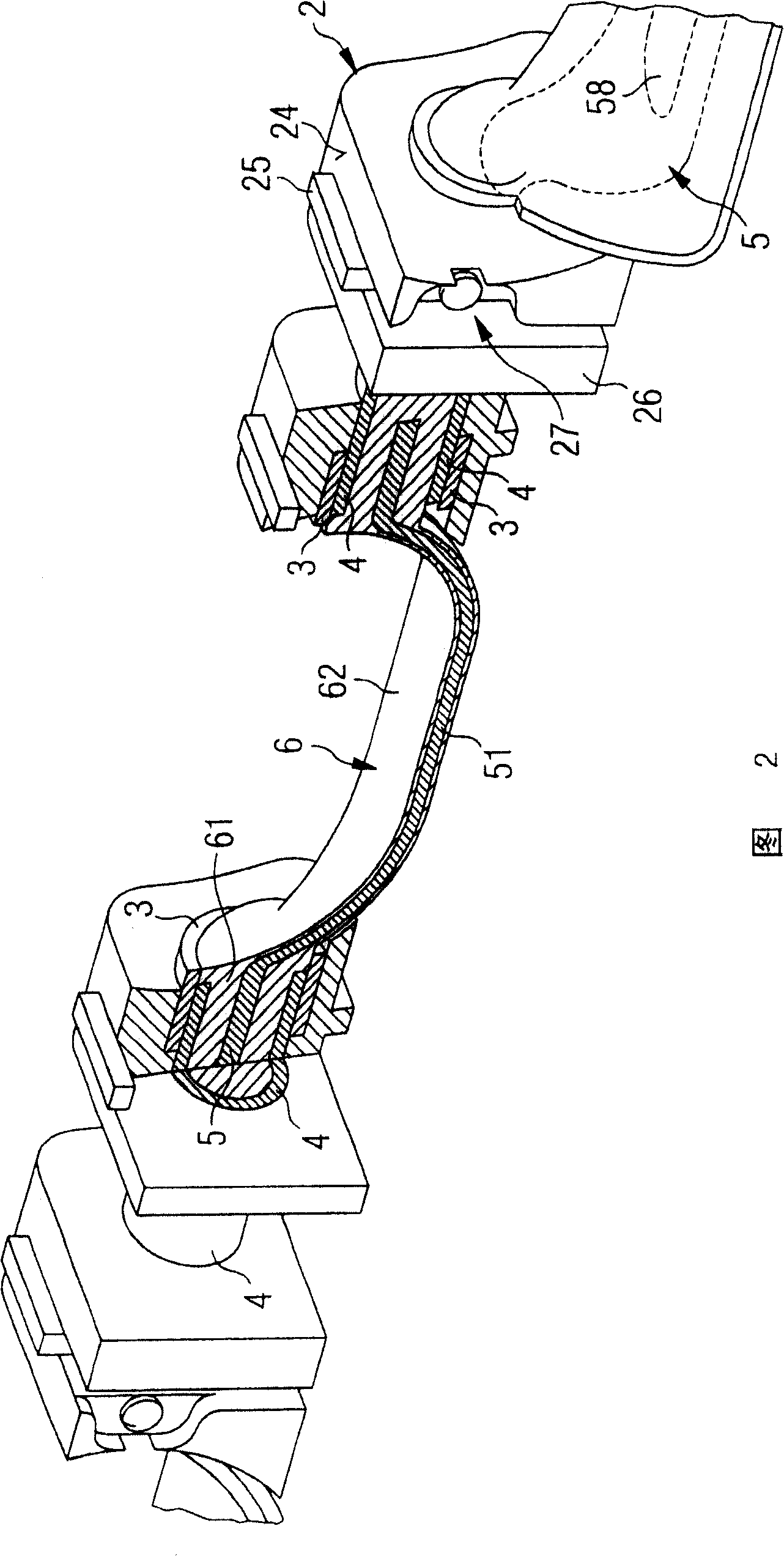

[0018] FIG. 2 likewise shows a valve system according to the invention, the section shown in FIG. 2 passing perpendicularly through the axis of rotation of the valve system 1 . Parts of another valve including components can also be seen on the right side of FIG. 2 .

[0019] A support member 2 is substantially cuboid. A bore 23 passes through the two opposing surfaces 21 and 22 , which bore is suitable for receiving either the bearing sleeve 3 , the hollow shaft 6 or the elastic housing 6 . A third surface 24 has a guide shoulder 25 . This guide shoulder 25 is guided in a groove formed in an intake pipe (not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com