Stereo hydro-entangled master drum and non-woven rag

A jacquard drum and three-dimensional technology, which is applied in the field of three-dimensional spunlace jacquard drum and production, can solve the problems of inability to make non-woven cloths, etc., and achieve the effect of clear mesh and improved product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

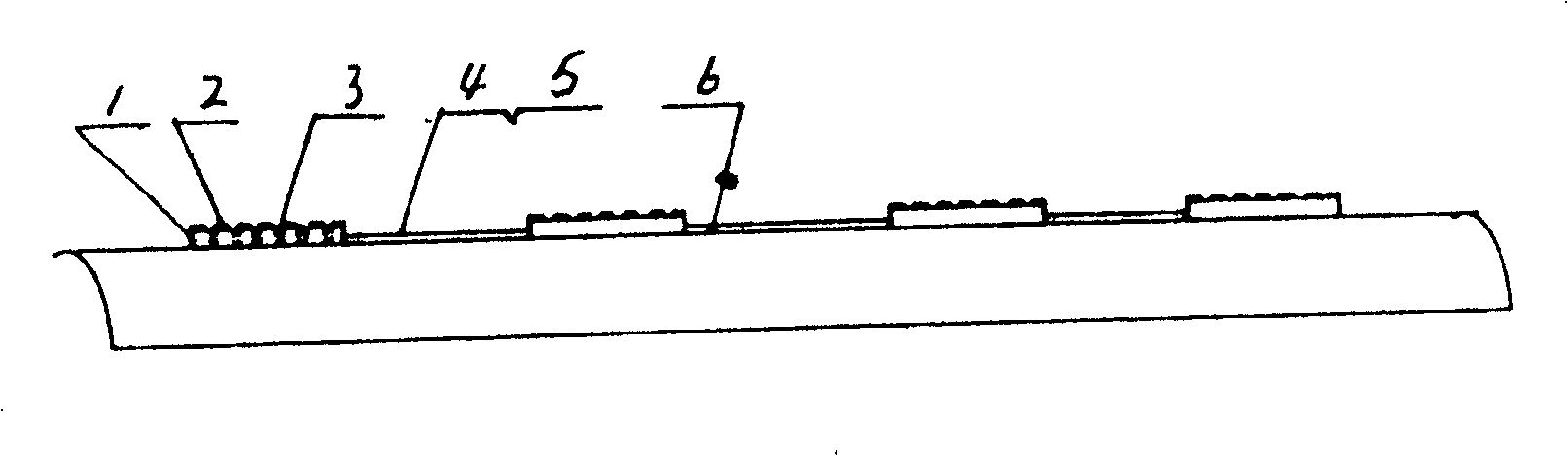

[0009] Example 1: Refer to the attached figure 1 . Three-dimensional spunlace jacquard drum, the surface of the jacquard drum is composed of a plurality of concave and convex three-dimensional square structures, and the surface of the concave three-dimensional square 3 is densely covered with a plurality of concave tiny concave blocks 2 or densely covered with a plurality of convex fine convexes The bar 6, the concave three-dimensional square 4 and the corners and corners of the concave three-dimensional square are connected to each other to form a concave-convex jacquard drum surface. The area of the tiny concave block 2 is less than 2 (0.1 or 0.2 or 0.3 or 0.4 or 0.5 or 0.6 or 0.7 or 0.8 or 0.9 or 1.0 or 1.1 or 1.2 or 1.3 or 1.4 or 1.5 or 1.6 or 1.7 or 1.8 or 1.9 or 1.95) square Mm. The surface of the convex three-dimensional square is densely covered with a plurality of convex thin convex strips 6, the width of the thin convex strips 6 is less than 2 (0.1 or 0.2 or 0.3 or 0.4...

Embodiment 2

[0012] Example 2: On the basis of Example 1, a method for manufacturing a three-dimensional spunlace jacquard drum, which includes a jacquard drum. First, the drum surface of the jacquard drum is equally divided into a plurality of concave-convex squares (the concave-convex squares are marked with marks) and Concave-convex squares are carved into concave three-dimensional squares and convex three-dimensional squares with precision engraving machines or engraving tools. ① Divide the surface of the concave three-dimensional square into multiple tiny square concave blocks or equally carved into multiple convex ones. Thin convex strips, small square concave blocks or thin convex strips are densely packed with a number of micro dehydration elongated holes, ②The surface of the convex three-dimensional square is divided into a number of convex thin convex strips or carved into a number of micro squares. There are many micro dehydration long strip holes densely between the concave blocks,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com