Vortex cold medium coiler and fin-free condenser

A type of condenser and scroll technology, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve problems such as refrigerant leakage, waste, and inability to remove scale, to eliminate pressure drop, save manufacturing costs, and eliminate Effect of Weld Leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

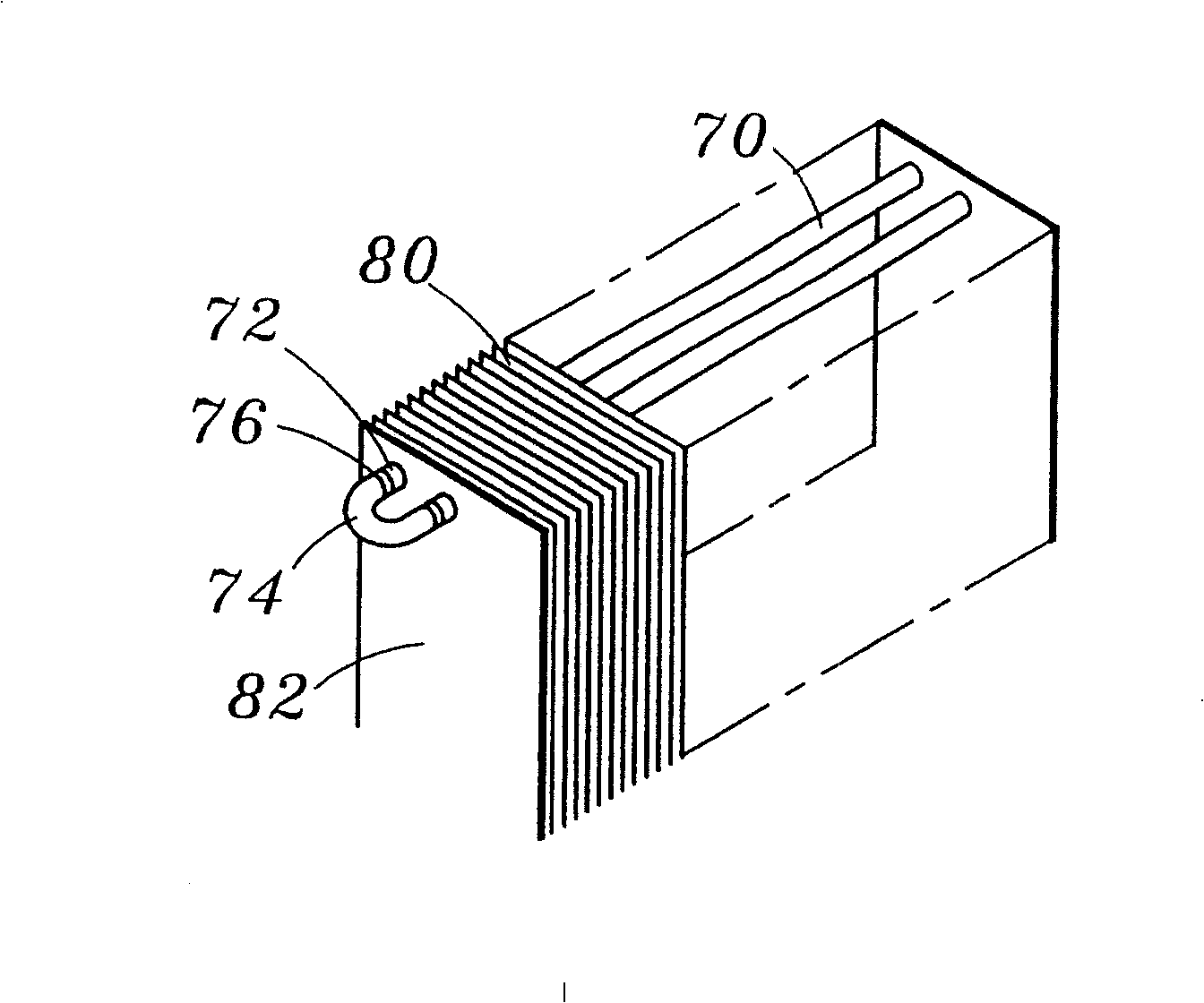

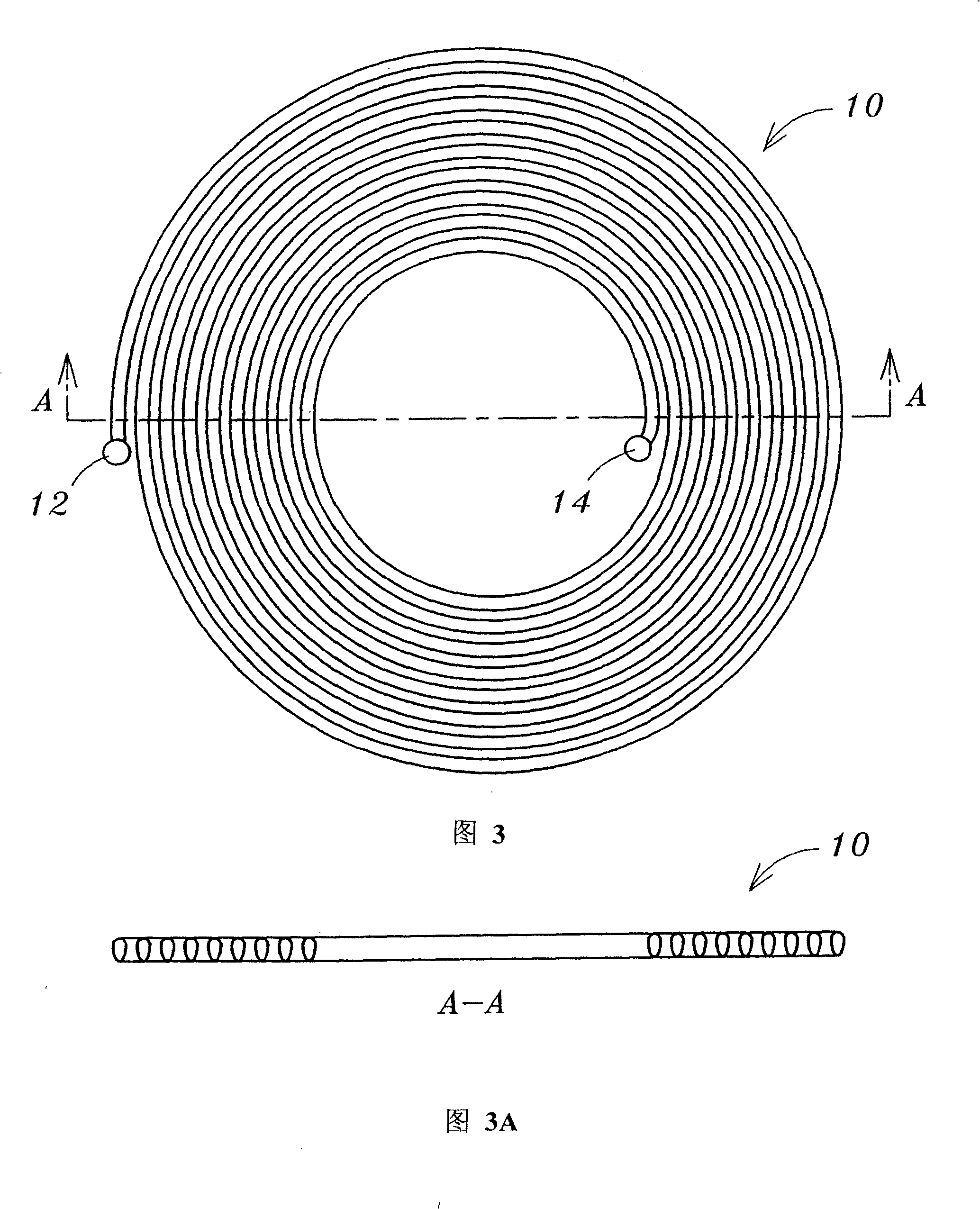

[0047] Embodiment: Please refer to Fig. 3, which is one of the preferred embodiments of the present invention, a flat spiral type refrigerant coil 10 (hereinafter referred to as "refrigerant coil 10") formed by coiling streamlined section tubes. ”) as the basis, its peripheral inlet end is connected to a distribution pipe 12, and the vapor refrigerant enters the refrigerant coil 10 through the distribution pipe 12, and its inner outlet is connected to a collection pipe 14 to collect the liquefied liquid refrigerant . This embodiment takes a streamlined section pipe as an example, but those familiar with the field of the present invention should understand that the scope of this case is not limited thereto.

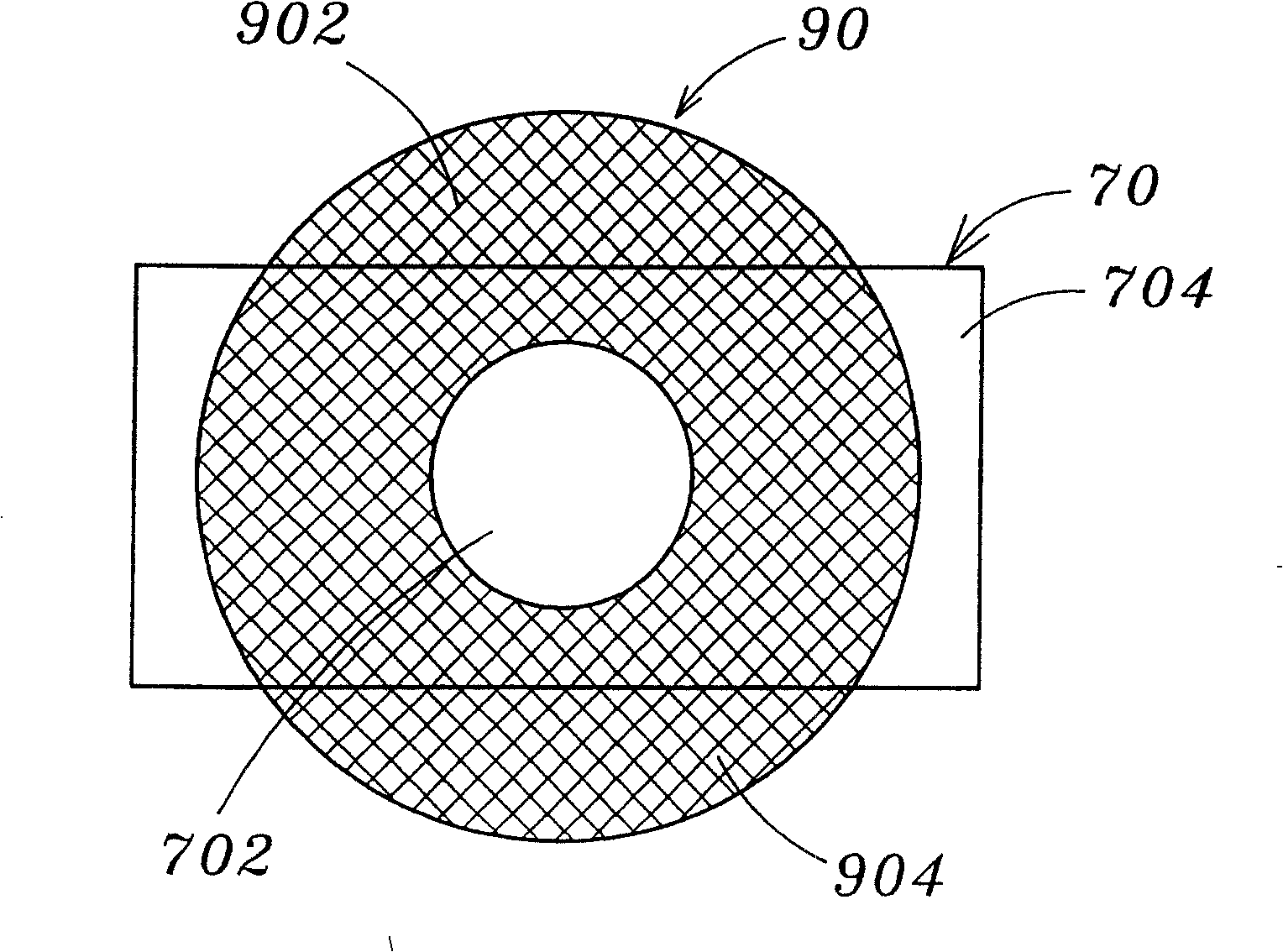

[0048] FIG. 4 is a cross-sectional view of a group of coils 100 formed by a plurality of layers of refrigerant coils 10 and 10'. Among the refrigerant coils 10 in odd layers, the gaseous refrigerant inlet distribution pipe 12 is located on the outside of the left side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com