Maintenance timing detection mechanism of brake controlling device for railway vehicle

A technology for a railway vehicle and a control device is applied in the field of a maintenance period detection mechanism using a brake control device, and can solve the problems of low reliability of detection accuracy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

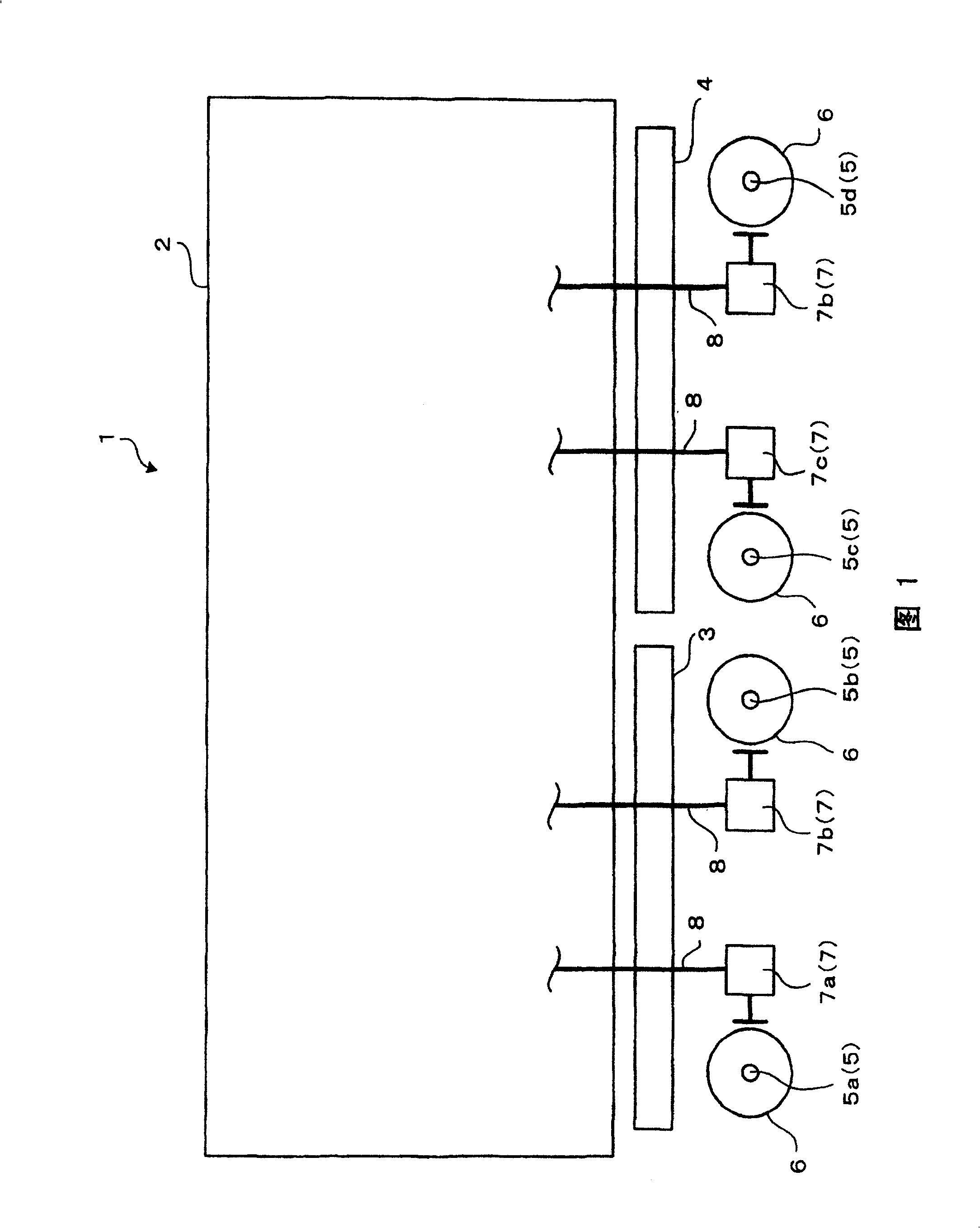

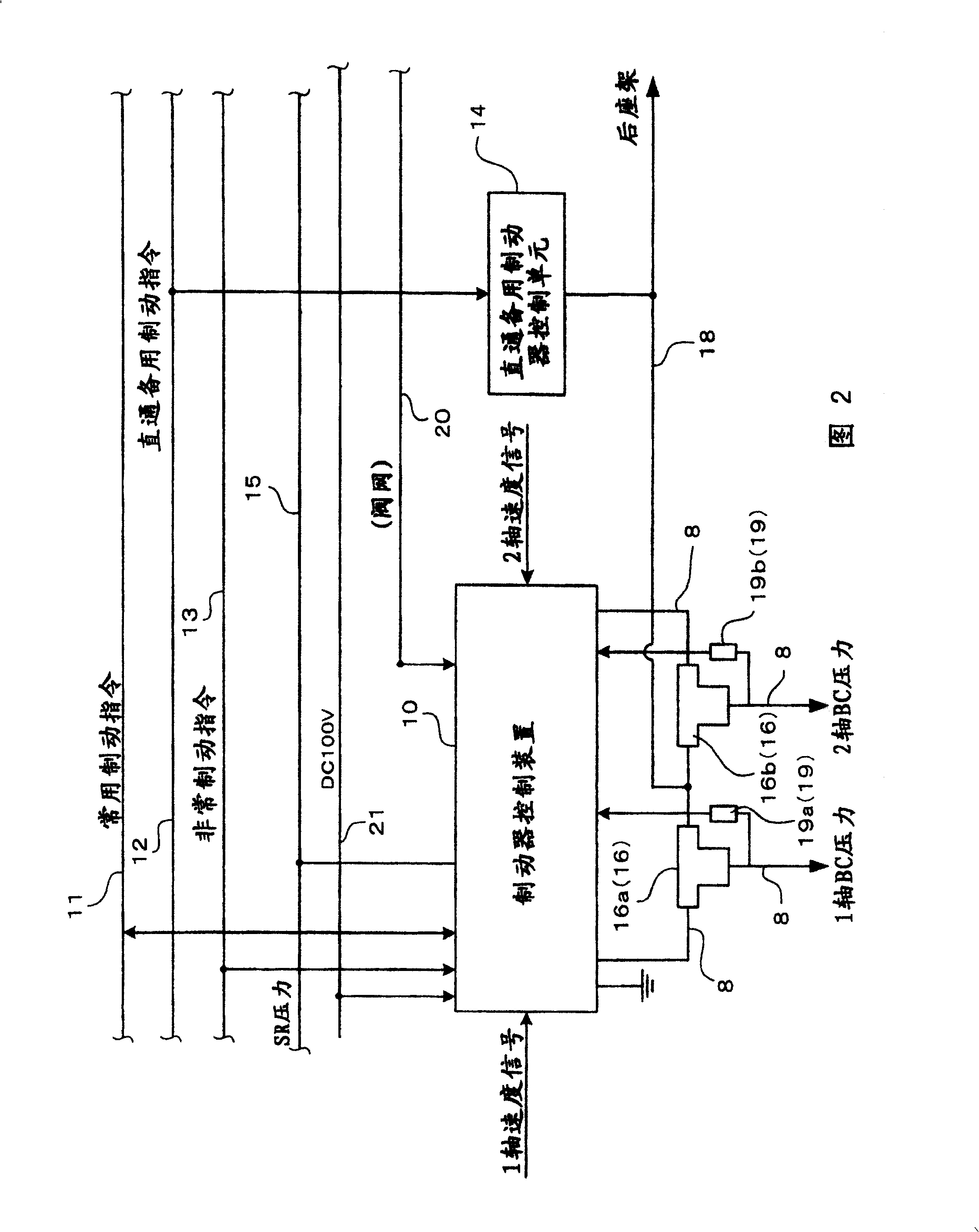

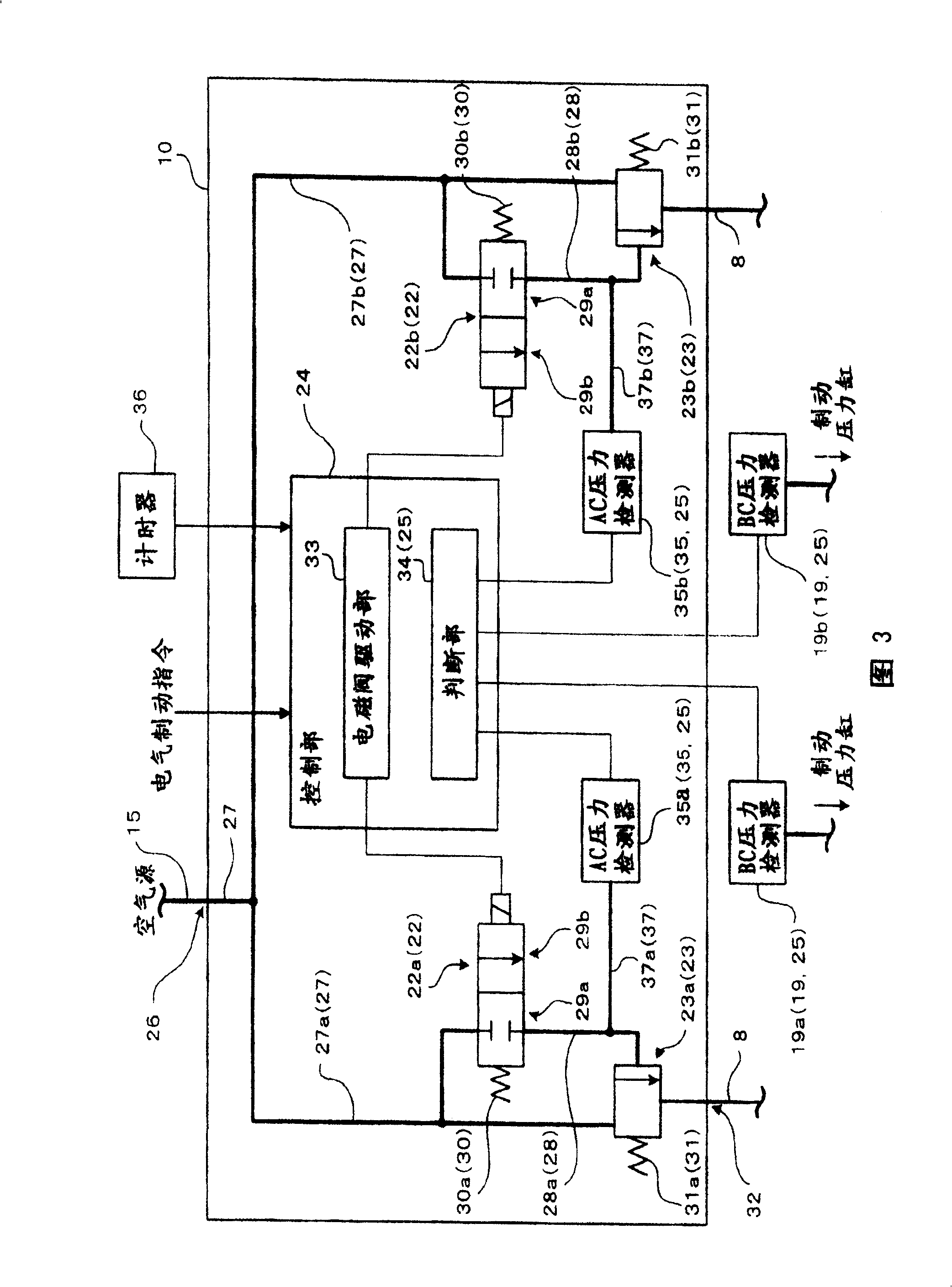

[0033] Next, preferred modes for implementing the present invention will be described with reference to the drawings. FIG. 1 is a schematic diagram illustrating a part of a railway vehicle 1 , and is a diagram for explaining a railway vehicle brake to which a maintenance timing detection mechanism of a railway vehicle brake control device according to an embodiment of the present invention is applied. As shown in FIG. 1, a car body 2 in a railway vehicle 1 is supported by underframes 3-4 provided at the front and rear. Two axles 5 are respectively provided on the chassis 3-4, and two wheels 6 are mounted on the left and right sides (both sides in the direction perpendicular to the drawing) on each axle 5 (5a-5d). Moreover, each brake cylinder 7 (7a-7d) which applies braking force to each axle|axle 5 (5a-5d) is attached to the base frame 3·4. The brake cylinder 7 applies a braking force to the axle 5 by actuating a brake shoe in contact with the wheel 6 or a brake shoe in co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap