Machine vision based LCD spot flaw detection method and system

A technology of liquid crystal display and machine vision, which is applied in the direction of optical testing flaws/defects, instruments, image data processing, etc., and can solve problems such as difficulties in automatic detection of spot defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

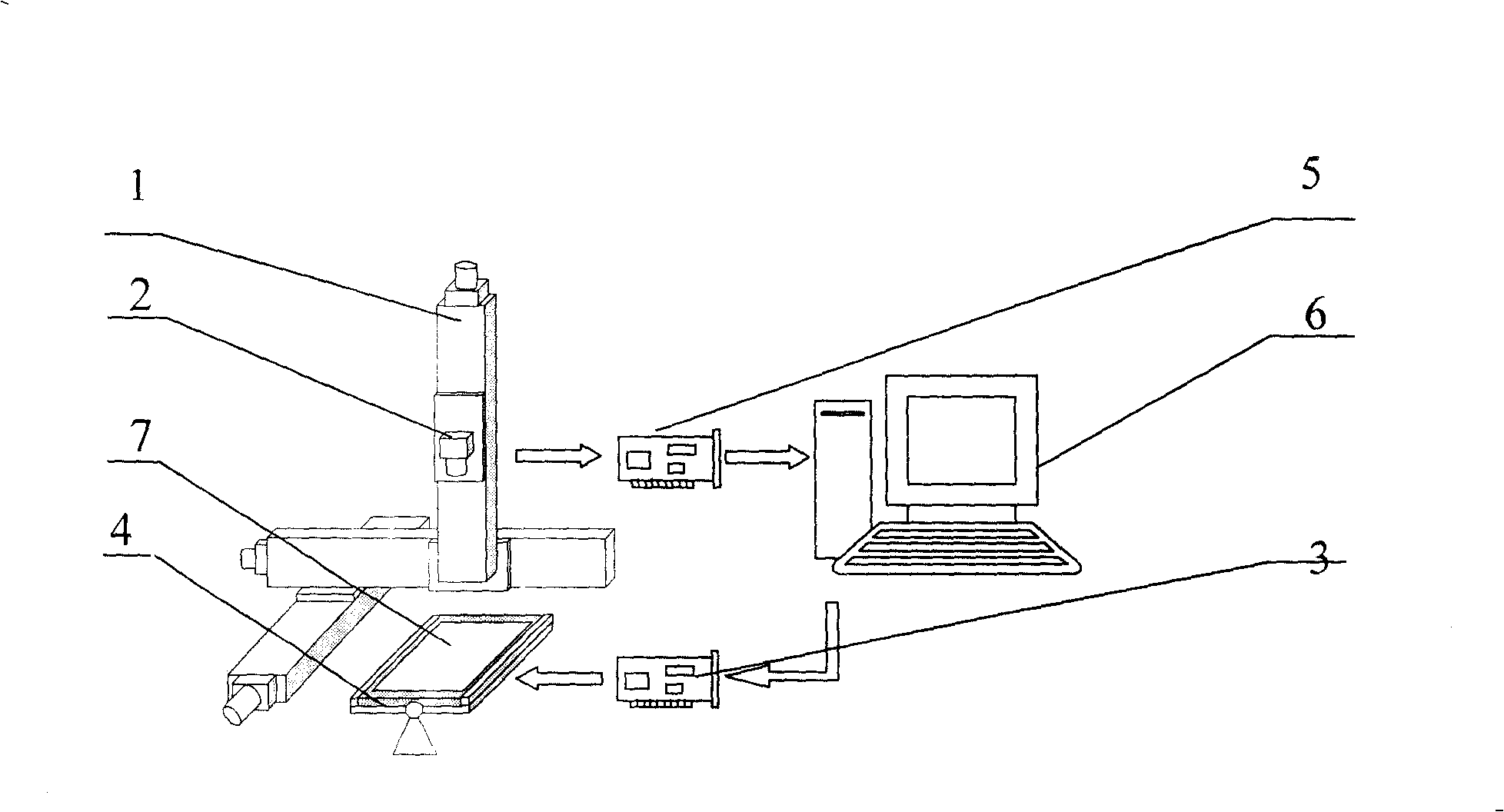

[0028] refer to figure 1 In this specific embodiment, the liquid crystal display defect detection system is composed of a CCD camera 2, an image acquisition card 5, a computer 6, a three-axis precision positioning platform 1, a liquid crystal display drive module 3 and a stage 4. The stage 4 is fixedly connected to the three-axis precision positioning platform 1, and is connected to the interface of the dedicated display driver module 3 through a cable. On the stage 4, the CCD camera 2 is fixed on the three-axis precision positioning platform 1 as an image acquisition device, so that it can move to a corresponding position under the control of the computer 6 according to the model of the liquid crystal display 7 to be tested for image acquisition.

[0029] The image acquisition card 5 is a standard analog or digital image acquisition card, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com