Viscoelastic vibration reducer

A shock absorber and viscoelastic technology, which is applied in the field of shock absorbers for suspension devices, can solve the problems of short life, poor buffering and damping effect, poor heat dissipation, etc., and achieve the effects of long life, improved operating efficiency, and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

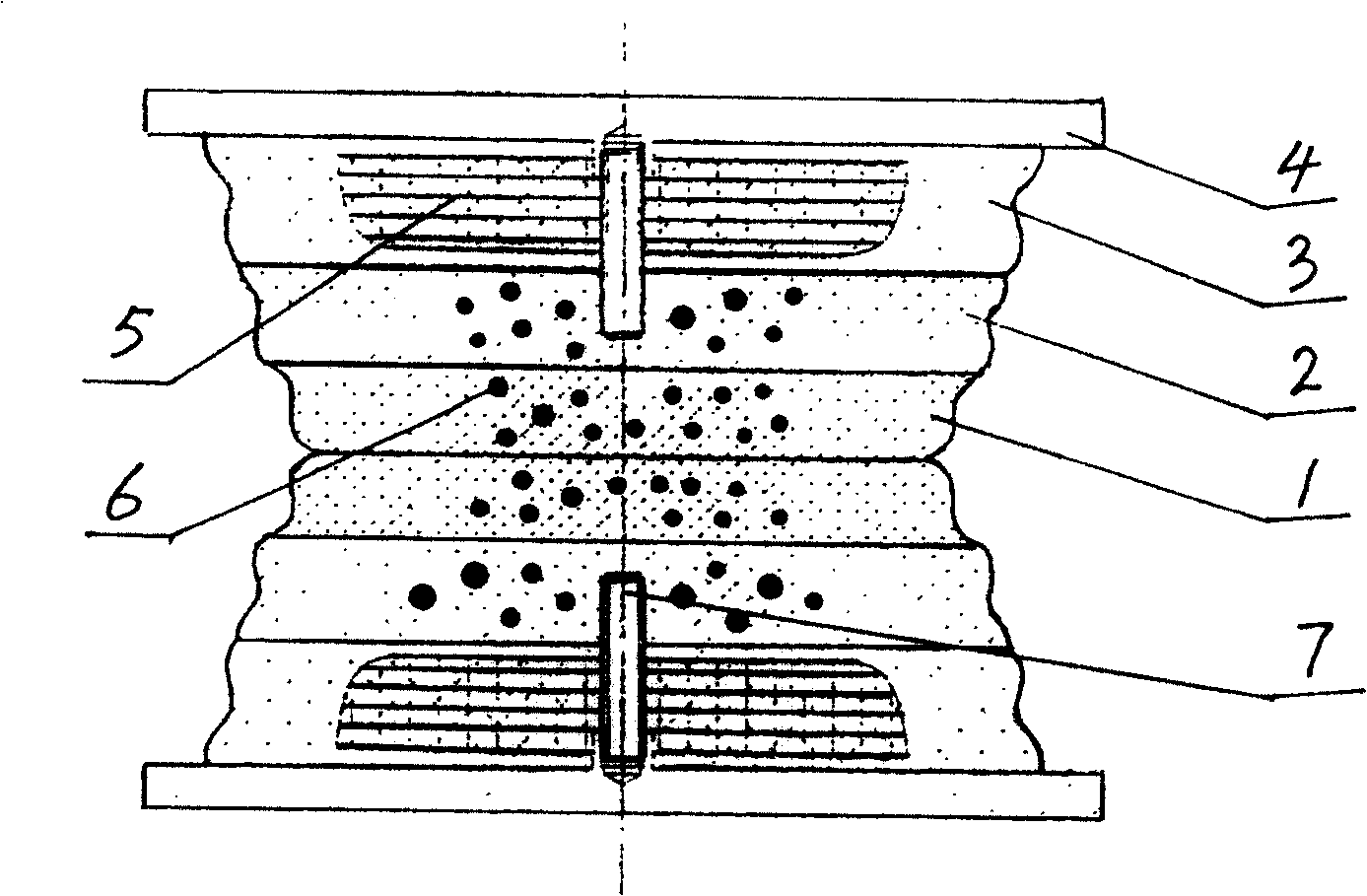

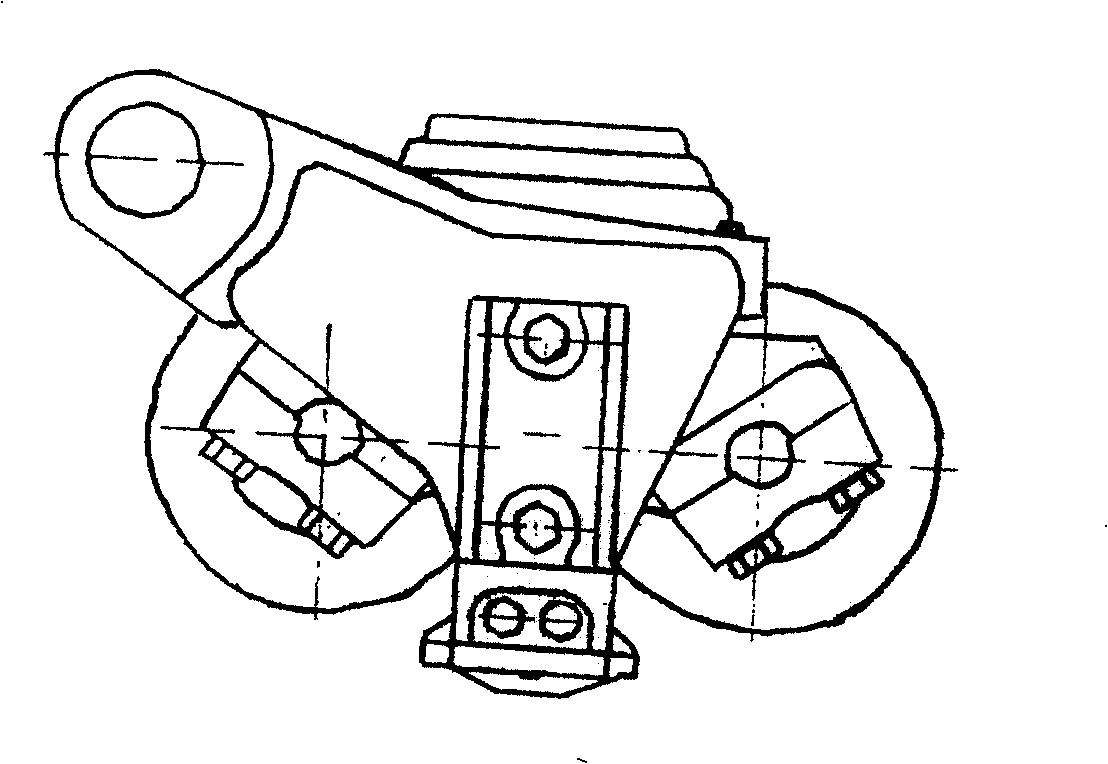

[0055] Embodiment 1: The viscoelastic suspension mechanism that is used for the traveling mechanism of the large-scale crawler bulldozer of 300kW

[0056] For crawler bulldozers, the mass is 50,000kg (not including the mass of the scarifier), and the working environment temperature is between -40°C and 50°C.

[0057] In order to meet the cushioning performance of the viscoelastic shock absorber under the comprehensive working conditions of construction machinery, the rubber layer is designed with natural rubber. The total height of the rubber layer is designed according to its compression amount. In order to ensure that the bulldozer has good vibration damping effect and good working stability during operation, the maximum compression amount of the rubber layer should be its total height. 15% to 40% is more reasonable. The diameter of the elastic constrained layer 4 is 400mm and the height is 20mm; the diameter of the basic rubber layer 3 is 350mm and the height is 60mm; the d...

Embodiment 2

[0058] Example 2: Support assembly under unloading compartment for heavy dump truck

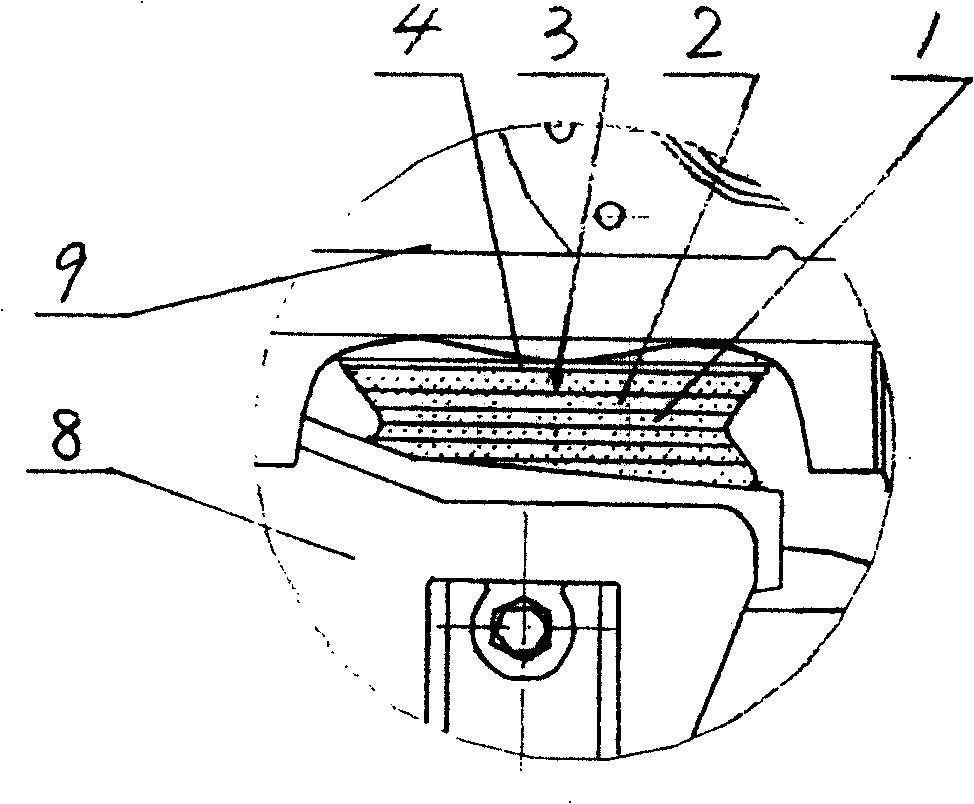

[0059] The upper half of the viscoelastic shock absorber is installed on the unloading carriage, and the lower half is installed on the frame. Elastic constrained layers 4 of metal materials are respectively used as connectors. The base rubber layer 3 is embedded with a φ0.5mm steel wire mesh; the middle rubber layer 2 and the contact rubber layer 1 are embedded with heat-conducting aluminum foil material wires.

Embodiment 3

[0060] Embodiment 3: The present invention can also be applied in the support of the foundation of large stamping machine tools

[0061] The upper half of the viscoelastic damper is installed on the base of a large press machine tool, and the lower half is installed on the foundation. Elastic constrained layers 4 of metal materials are respectively used as connectors. A φ2mm steel wire mesh is embedded in the base rubber layer 3; a φ0.5mm thermal conductive aluminum wire is embedded in the middle rubber layer 2 and the contact rubber layer 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com