Double-pipe relative measurement method and device for microflow of liquid

A technology of relative measurement and micro-flow, which is applied in the direction of measuring devices, fluid flow, hydrodynamic tests, etc., can solve problems such as the inability to improve the accuracy of pipe diameter measurement, and achieve the goal of improving relative measurement accuracy, eliminating the influence of geometric errors, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

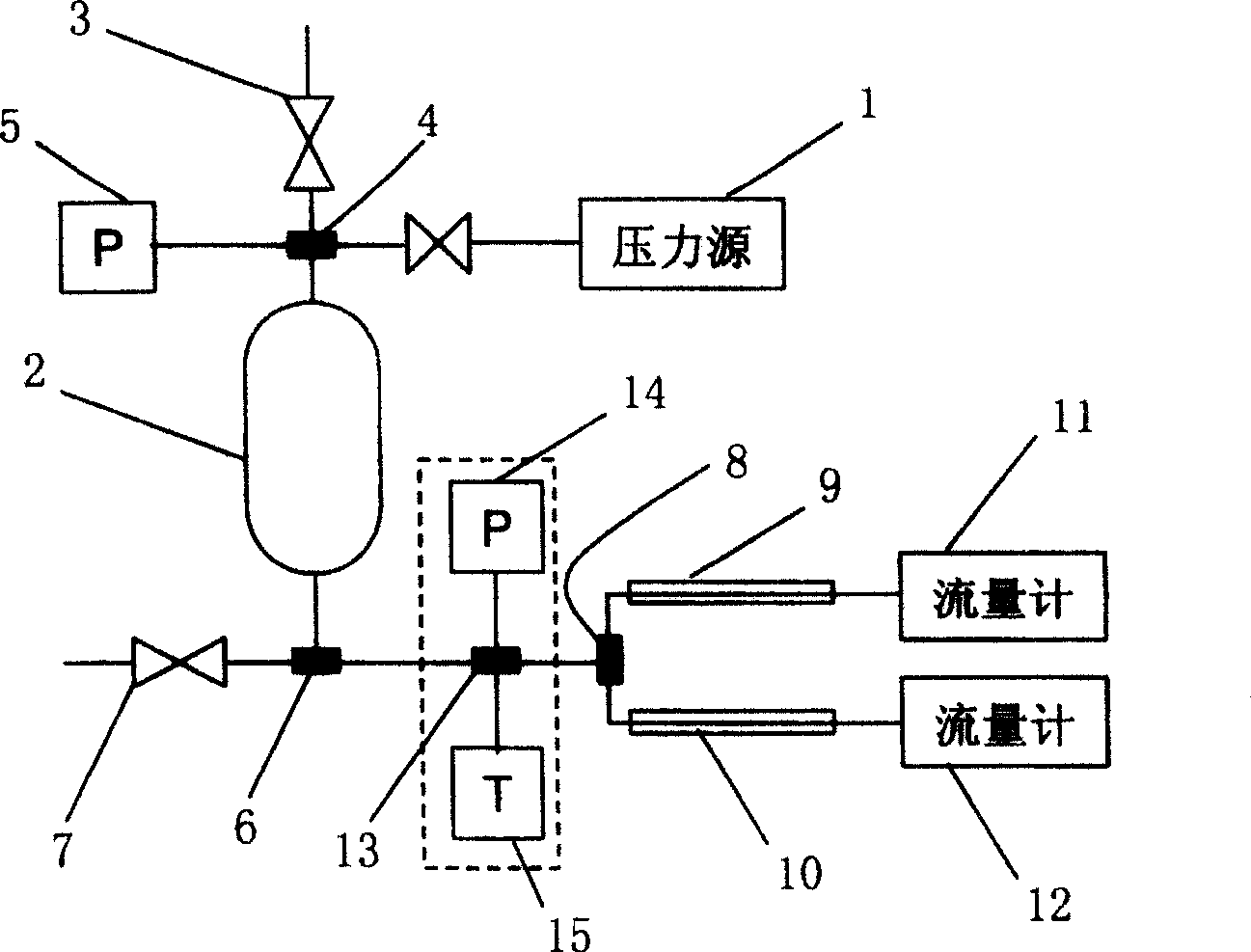

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0037] Measuring principle of the present invention is as follows:

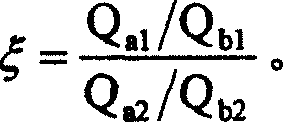

[0038] Take the measurement of the wall effect of water in a micropipe as an example. Two parallel capillary micro-channels a and b are used as the experimental objects, one of them, for example, the inner surface of tube a is treated with OTS molecular film to become a hydrophobic surface, and the inner wall of the other capillary micro-channel b is not treated, so that the two Under the same pressure and temperature, a capillary microtube is tested for the flow characteristics of water, and the following can be obtained:

[0039] Q a - water = π d a 4 P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com