Cold rolling steel coil inter semi-film whole-closed water-proof moisture-proof seal packing method

A packaging method and moisture-proof sealing technology, applied in the directions of packaging, paper product packaging, transportation and packaging, etc., to achieve the effect of easy operation, simple packaging method, and solving the problem of waterproof and moisture-proof.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

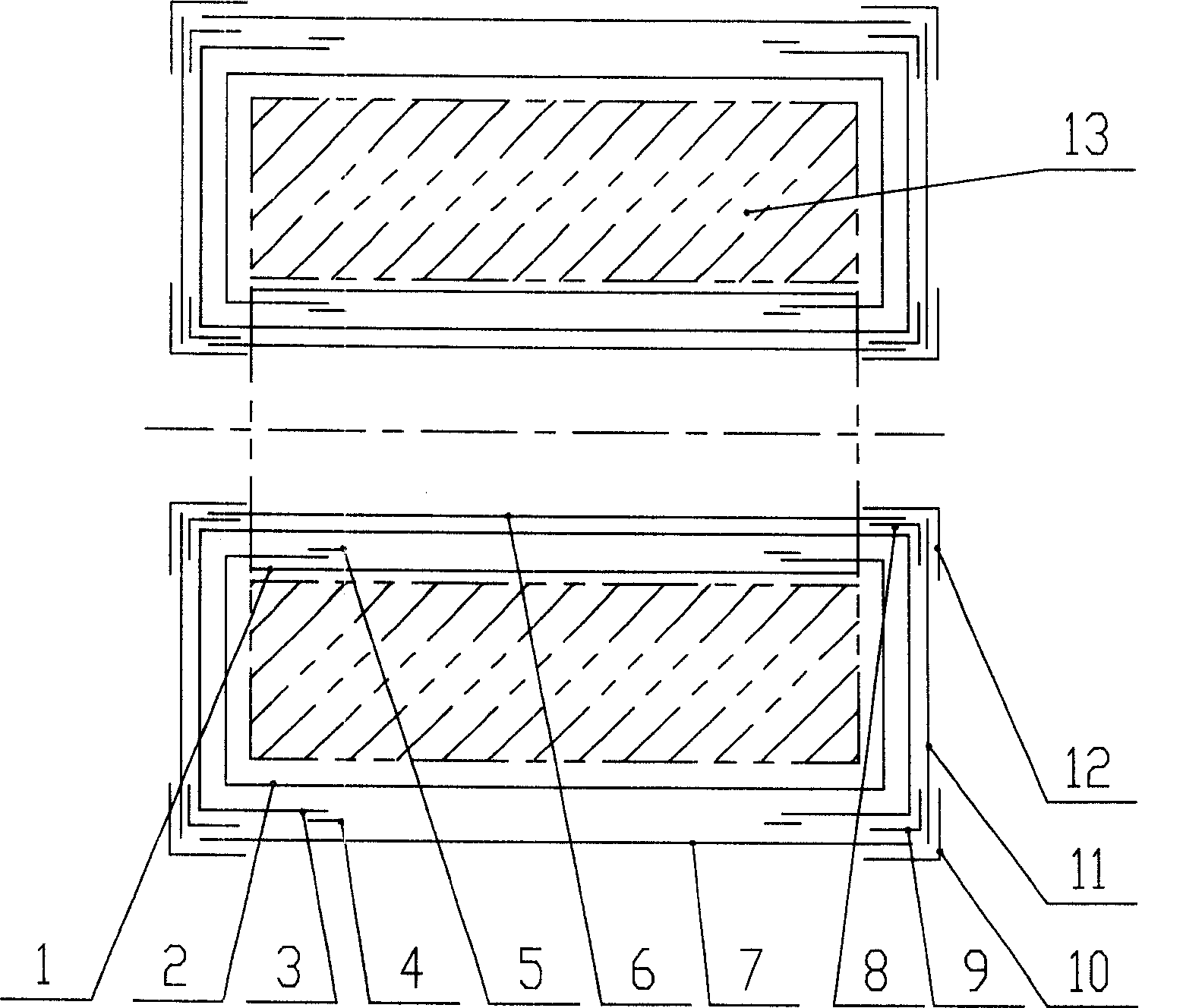

Image

Examples

Embodiment

[0011] Example: Our company has used the "Cold-rolled Steel Coil Internal Half-Membrane Fully Sealed Waterproof and Moisture-proof Sealing Packaging Method" of the present invention to carry out steel coil packaging tests for more than a year, and the steel coils that have been drenched by rain have not experienced water ingress in the steel coils. At the same time, our company conducts watering tests on steel coils after online packaging three times a week, and no water ingress incidents have occurred in steel coils.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com