Opening roller for rotor spinning machines

A rotor spinning machine and opening roller technology, applied in the field of steel wire saw racks, can solve the problems of increased pollution risk, unfavorable fiber damage, etc., and achieve the effect of improving the carrying function and preventing fiber damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

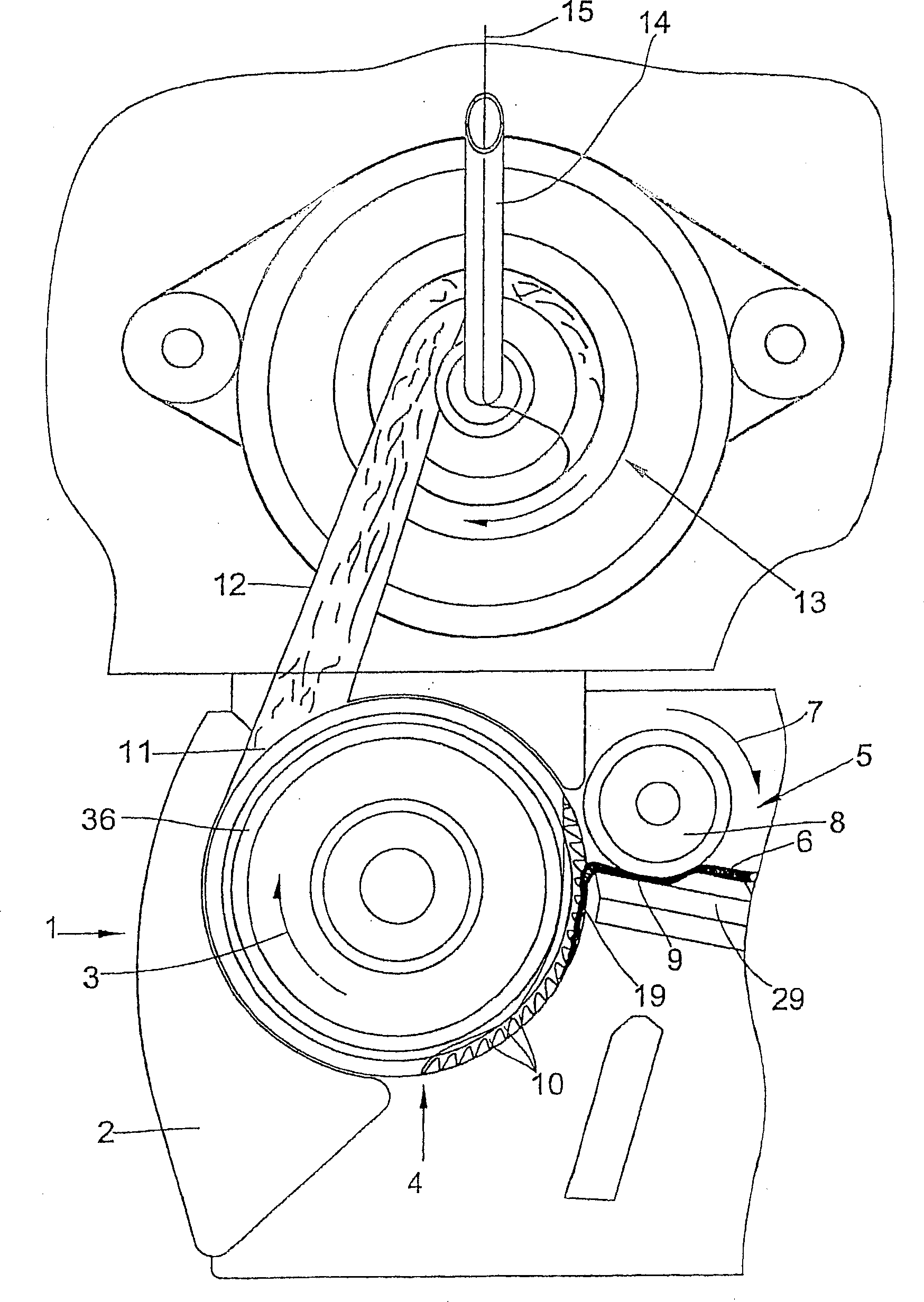

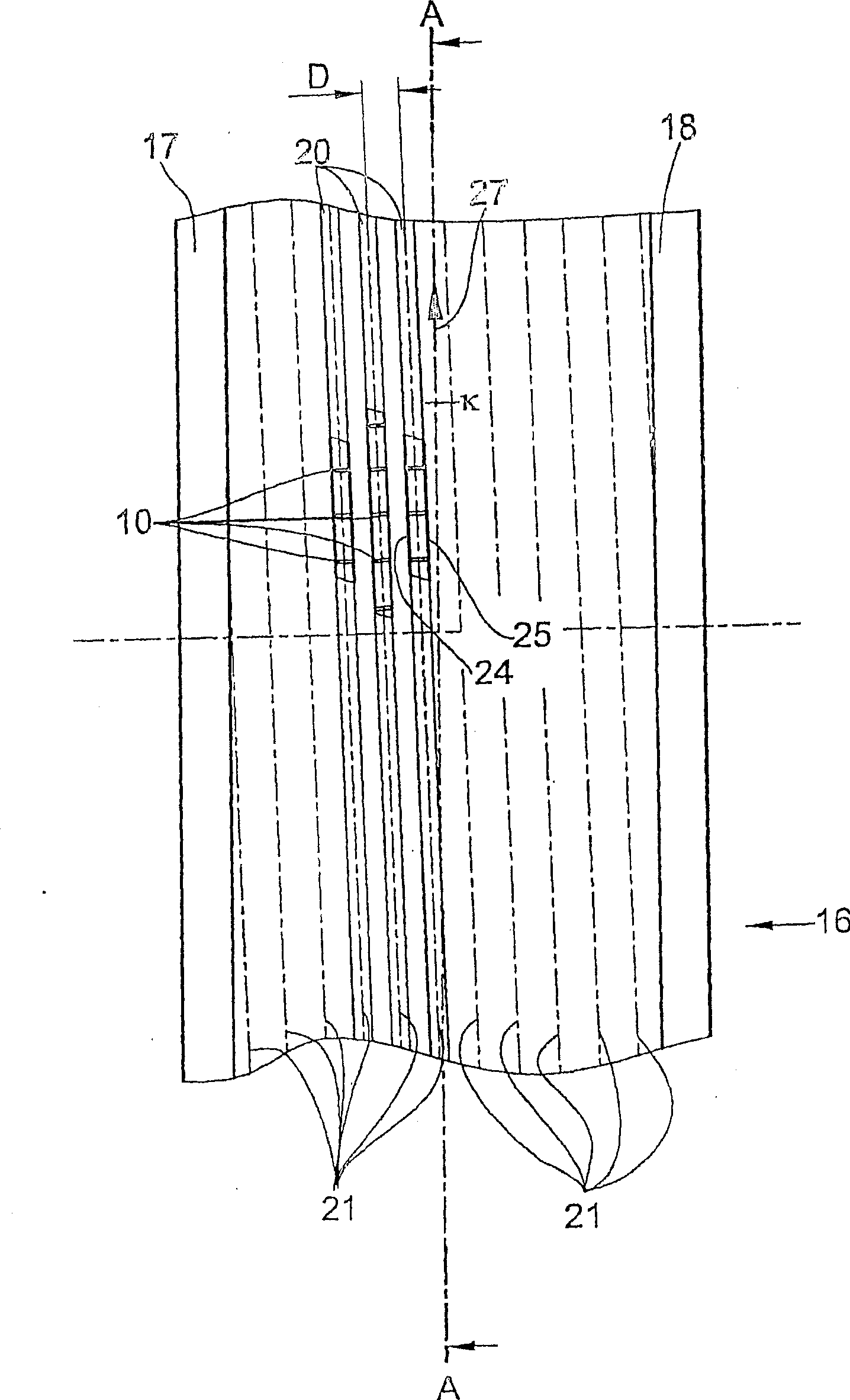

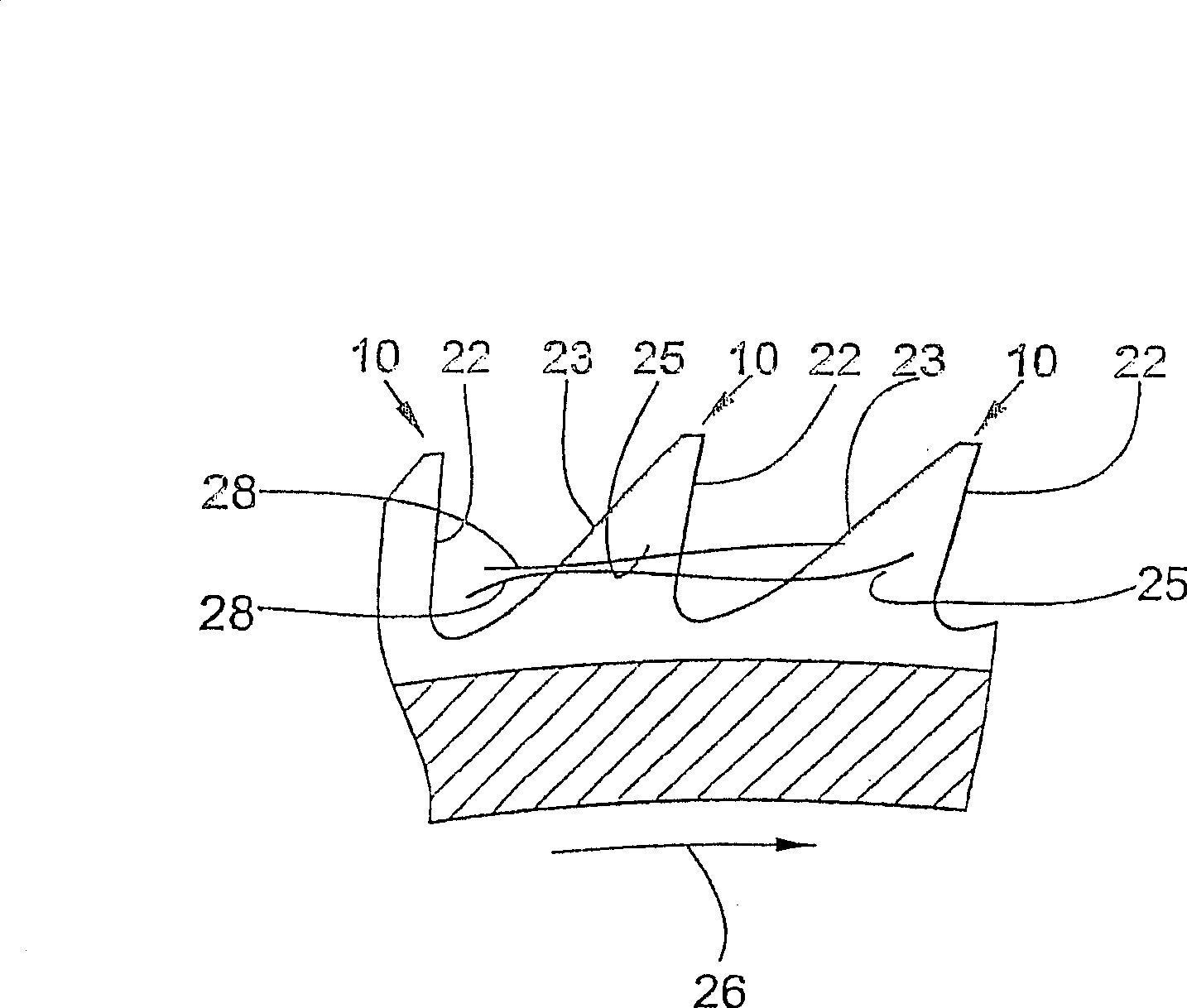

[0021] figure 1 The separating device 1 shown in includes an opening roller 4 which rotates in a housing 2 in the direction indicated by the arrow 3 . A feed device 5 is arranged upstream of the separating device 1 , by means of which the fiber web 6 is fed to the opening roller 4 . The feeding device 5 comprises a feed roller 8 which rotates very slowly relative to the opening roller 4 in the direction indicated by the arrow 7, which cooperates with a feed table 29 and is formed together with the feed table for the fiber Clamping position 9 for belt 6 . The supply roll 8 rotates continuously and conveys the fibers of the fiber strip 6 to the opening roll 4 . The opening roller 4 has a plurality of outwardly protruding teeth 10 on its circumference. The teeth can be produced, for example, by winding a wire saw tooth bar on the base body 36 of the opening roller 4 . If the fiber material of the fiber strip 6 reaches the range of action of the teeth 10 , a so-called fiber ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com