PE electric-melting pipeline valve

A pipeline valve, electrofusion technology, applied in the direction of pipeline connection layout, sliding valve, valve details, etc., can solve the problem that the standard of PE steel wire pipe cannot be used for 50 years, the cost of installation and use is increased, and the price of non-ferrous metals is expensive, etc. problems, to achieve the effect of reduced dimensional accuracy requirements, reduced sealing difficulty, and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

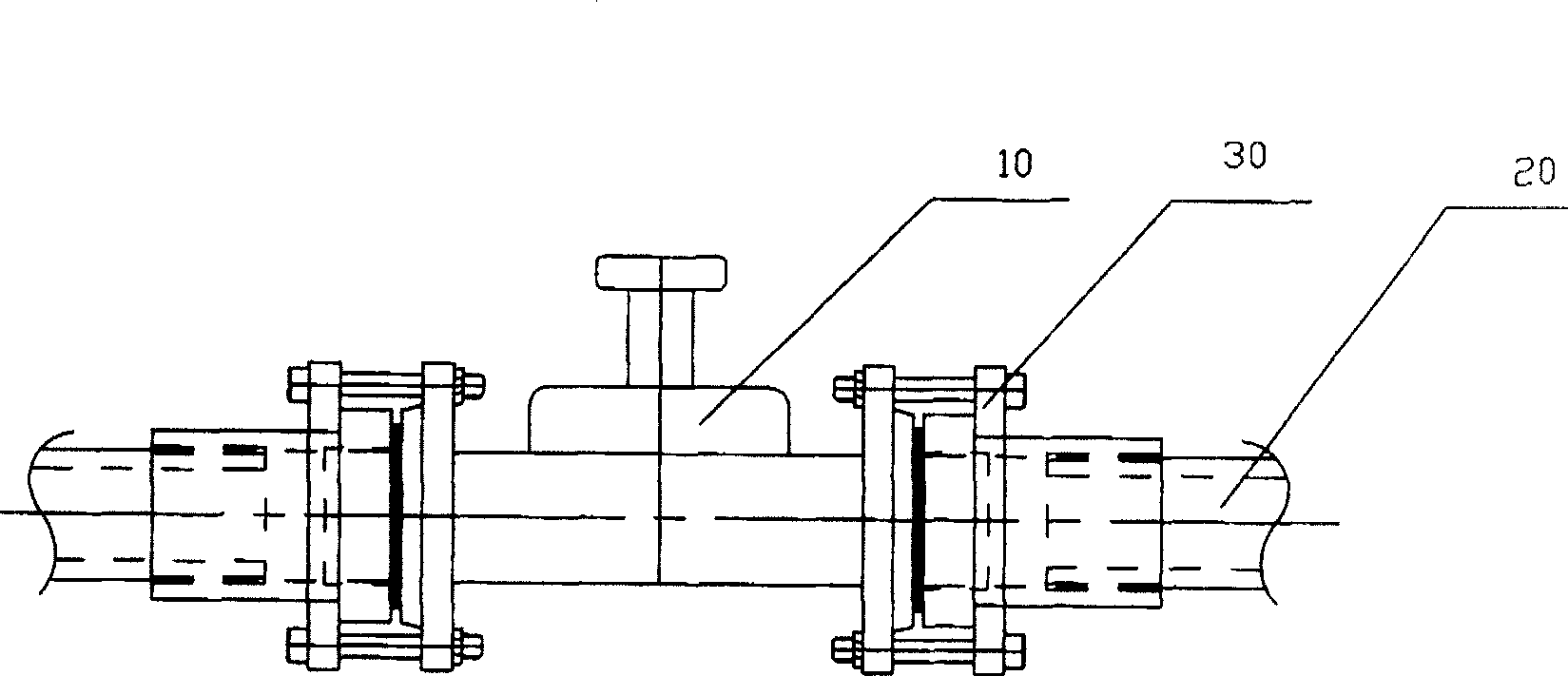

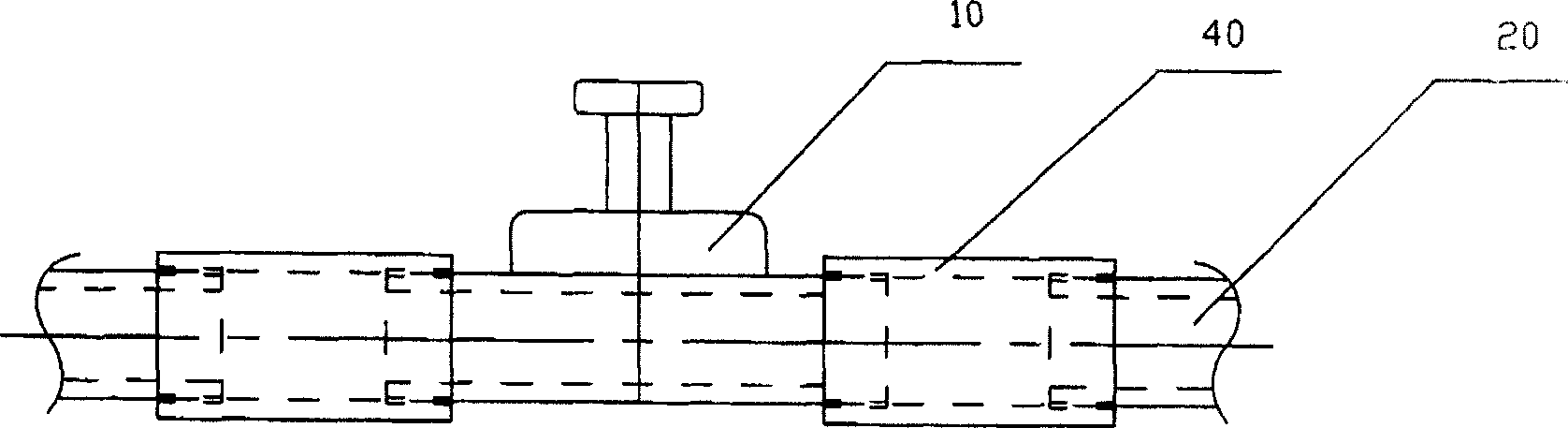

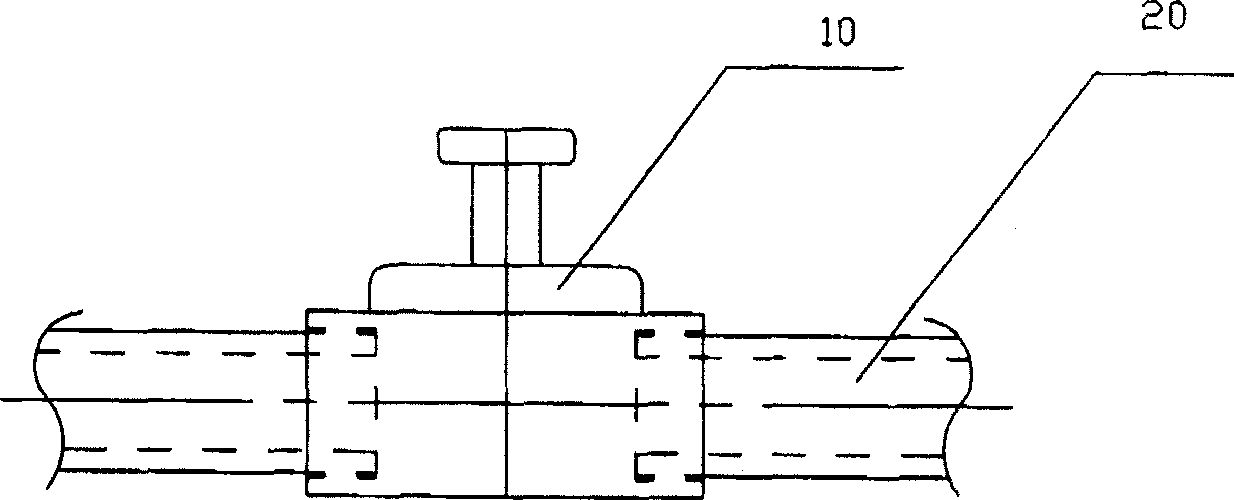

[0028] Such as Figure 4 As shown, a PE electrofusion pipeline valve of the present invention includes a valve body and a valve core. The lower part of the valve core is the sealing part of the valve core. A groove 2.

[0029] The inner walls of the pipes 6 at both ends of the valve body of the present invention are compounded with heating wires 5, the heating wires are two low-carbon steel heating wires juxtaposed, the heating wires are softened by annealing, surface polished, multi-layer copper plating anti-corrosion, Anti-oxidation treatment and plastic treatment, after plastic treatment, two parallel heating wires are directly wound and compounded on the inner wall at both ends of the valve body of the PE pipe valve.

[0030] Such as Figure 4 As shown, the tapered surface of the valve core sealing part of the present invention is composed of a left tapered surface 11 and a right tapered surface 12, and the taper of the left tapered surface is greater than that of the ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com