Grit chamber for wastewater treatment plant, capable of preventing sedimentation of organic material

A technology for grit chambers and sewage ponds, which is applied in the field of grit chambers, and can solve problems such as inability to guarantee reliable operation of grit chambers, abnormal operation, and reduced sewage treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Referring now to the drawings, wherein like reference numerals designate like or like parts throughout the various views.

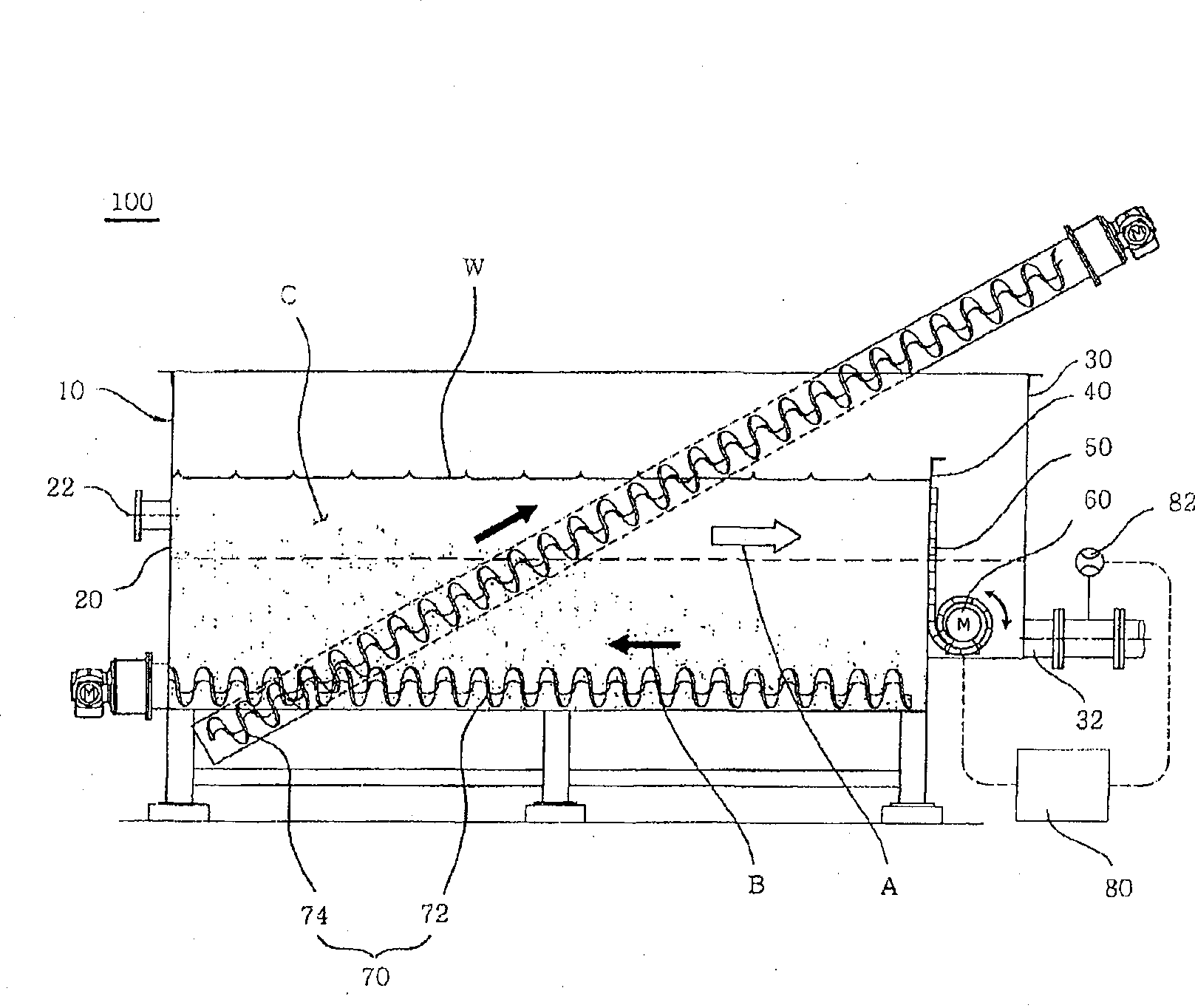

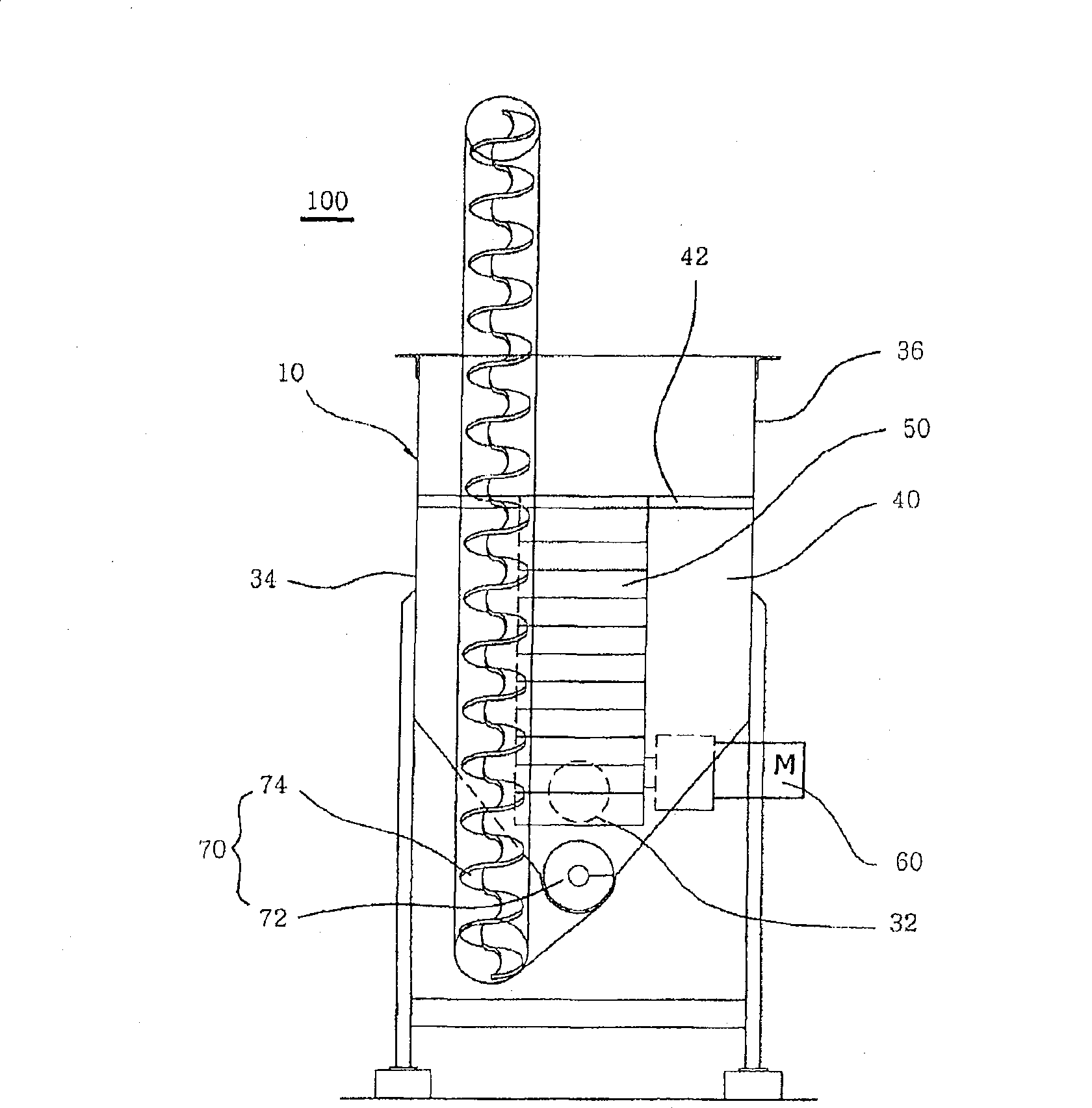

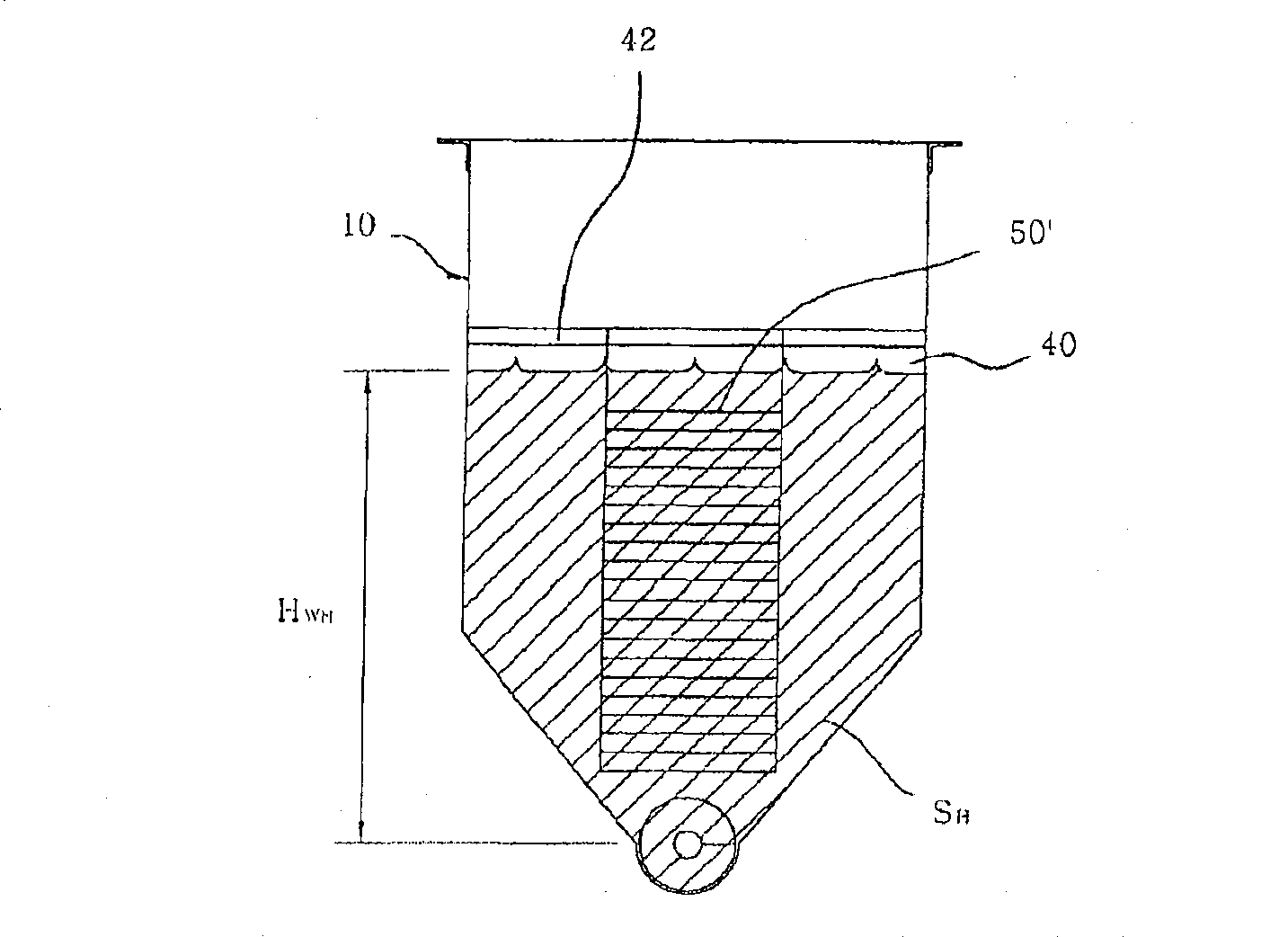

[0021] figure 1 To schematically represent a front view of an embodiment obtained by applying the invention to a mechanical grit chamber. figure 2 for figure 1 side view. refer to figure 1 and figure 2 , like a conventional mechanical grit chamber for treating sewage, a grit chamber 100 according to an embodiment of the present invention has a sewage pond 10 mainly made of steel. The sinkhole 10 has a rectangular configuration. Sinkhole 10 includes a front wall 20 defining a sewage inlet 22, a rear wall 30 facing the front wall 20 and defining a sewage outlet 32, and a pair of side walls 34 and 36 connecting the front wall 20 and the rear wall 30 to each other. Sewage is introduced into the sewage pool 10 through the sewage inlet 22 and discharged out of the sewage pool 10 through the sewage outlet 32. In order to prolong the retention time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com