Method for producing a threaded pipe joint, and suit assembly and sealing ring used therefor, and threaded pipe joint

A technology for sealing rings and threaded pipes, which is applied in the direction of threaded connections, connecting components, pipes/pipe joints/fittings, etc. It can solve the problems of increased pipe end thickness, increased cost, and cracks on the sealing surface, achieving simple sealing rings and simple The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

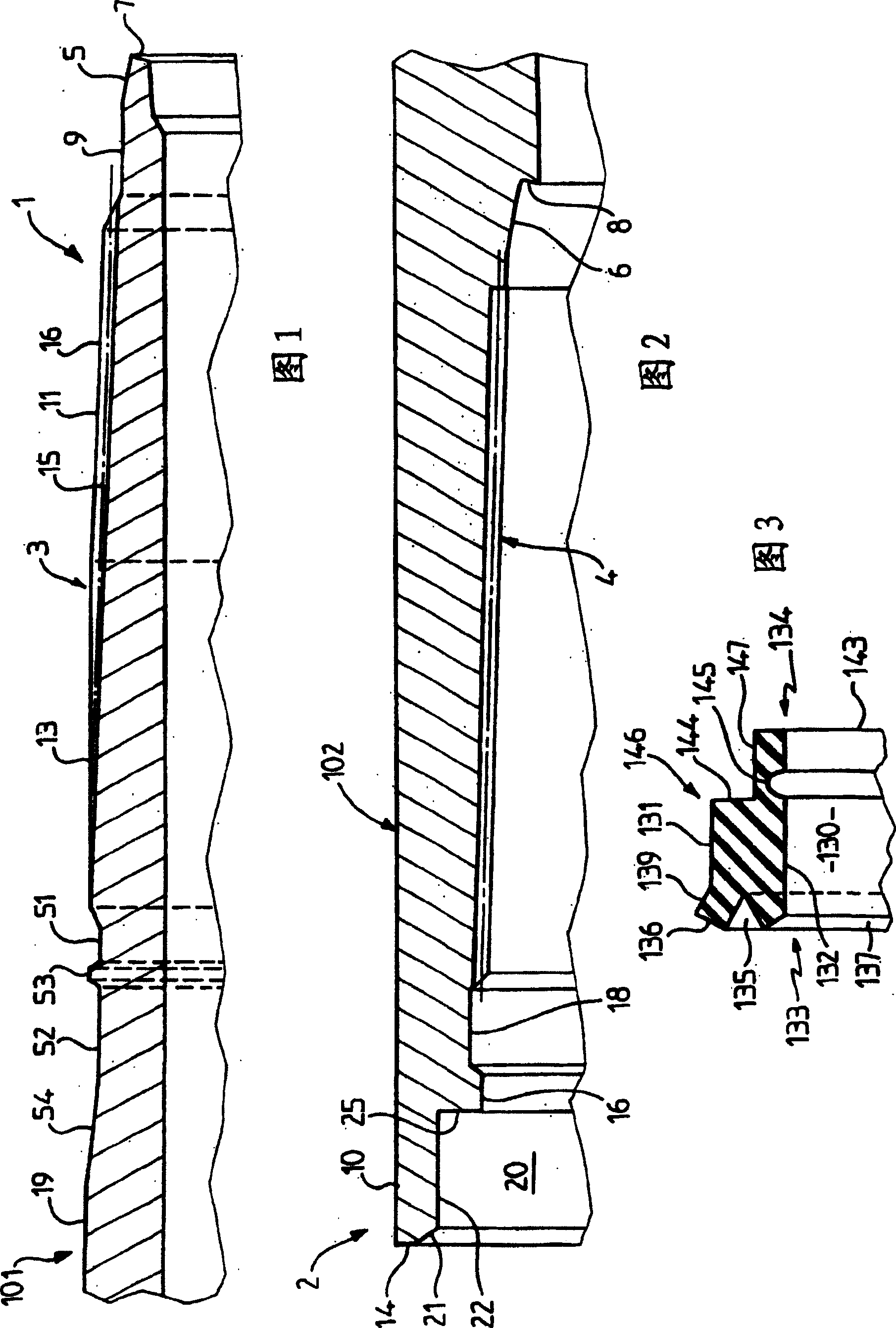

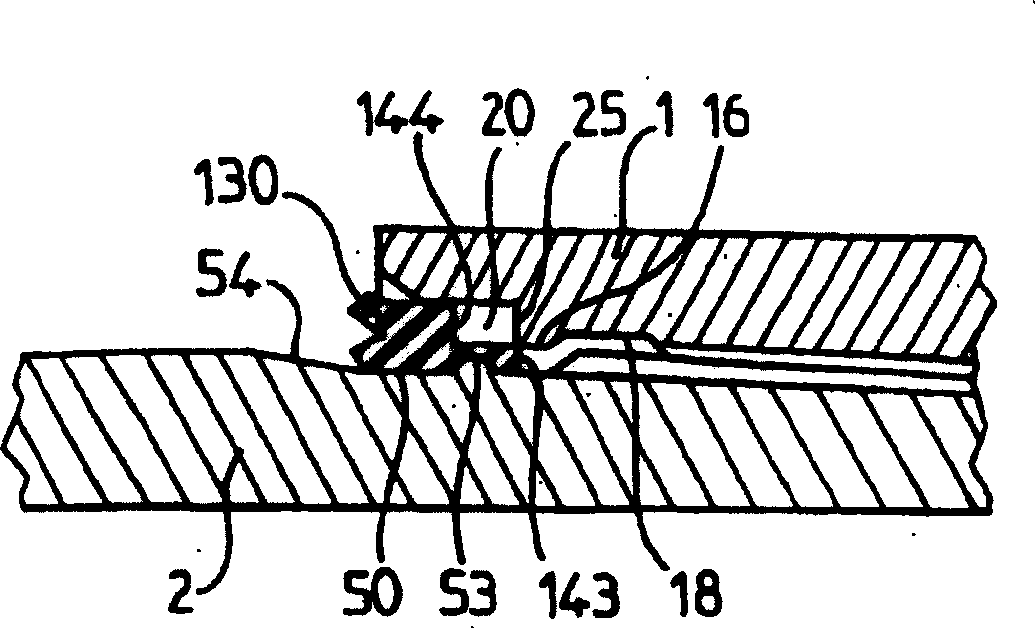

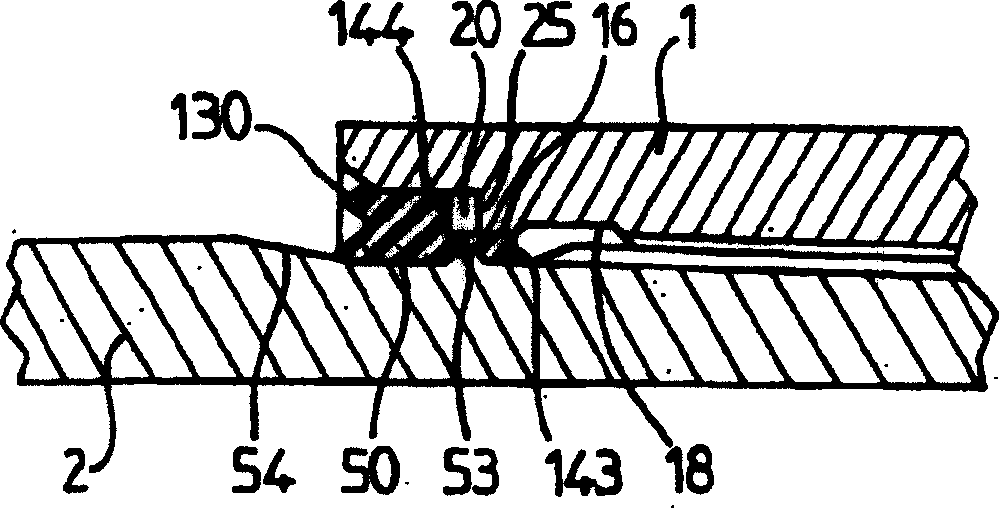

[0052] The drawings include the essentials of the character. Therefore, they are not only used to provide a better understanding of the description, but also help to define the invention when necessary.

[0053] The threaded male fitting or rod of Figure 1 is formed at one end of a very long tube 101, ie several meters long. It comprises a trapezoidal continuous tapered external thread 3 . Over a region 11 of its length, the thread 3 is formed by a complete thread with a constant thread height equal to the nominal value between the thread root envelope 15 and the thread crest envelope 16, both root and crest truncated cone. In the remaining area 13 of the thread, the thread is incomplete, or is the end of the thread, the envelope of the root of the frusto-conical thread extends to the envelope of the complete thread, the envelope of the top of the thread is defined by the cylindrical outer surface of the pipe 101 Surface 19 constitutes.

[0054] The tube 1 includes a male ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com