Spring element for rail vehicles

A spring element, elastic technology, applied in the field of "laminated springs, can solve the problems of rubber friction, wear and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

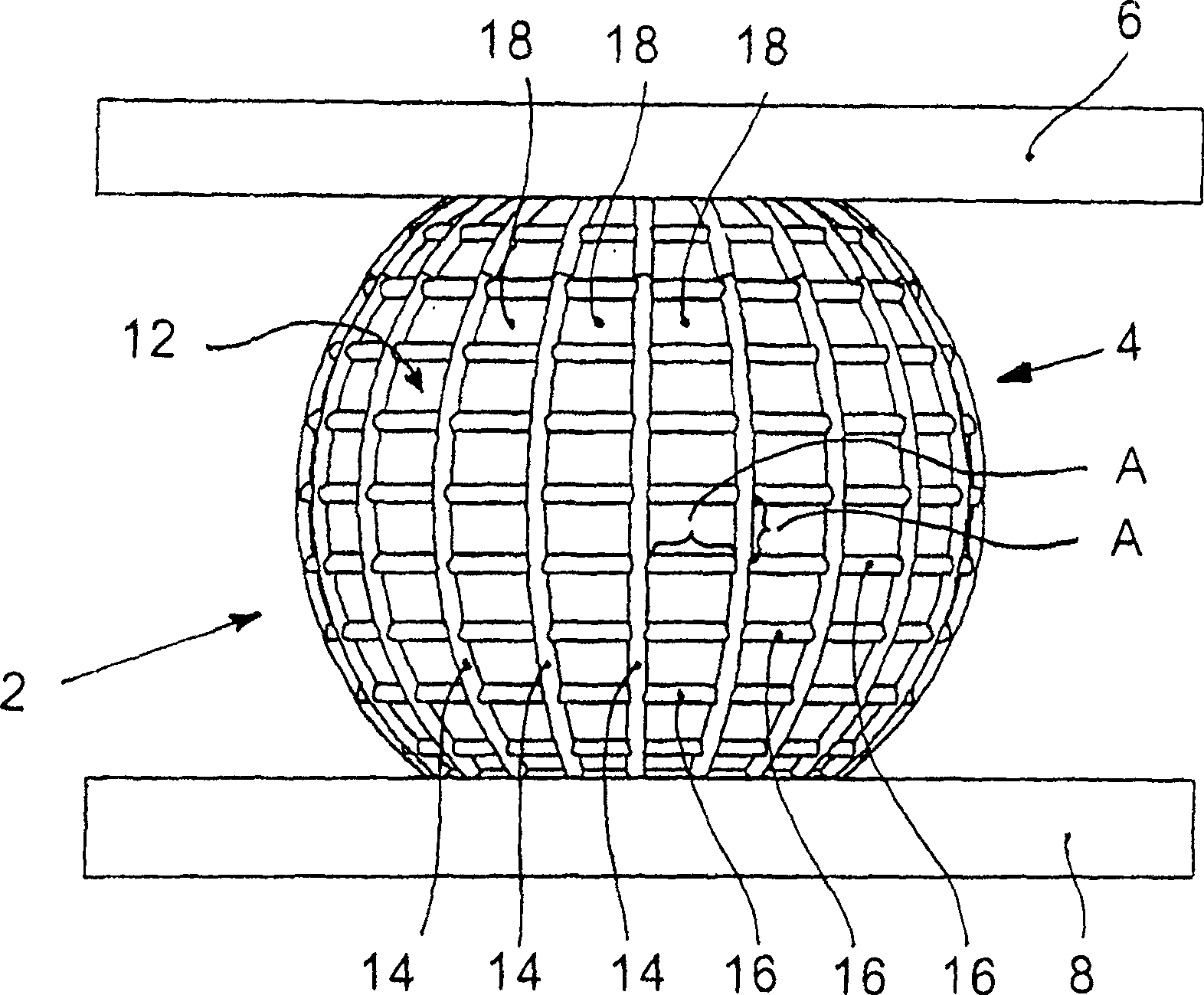

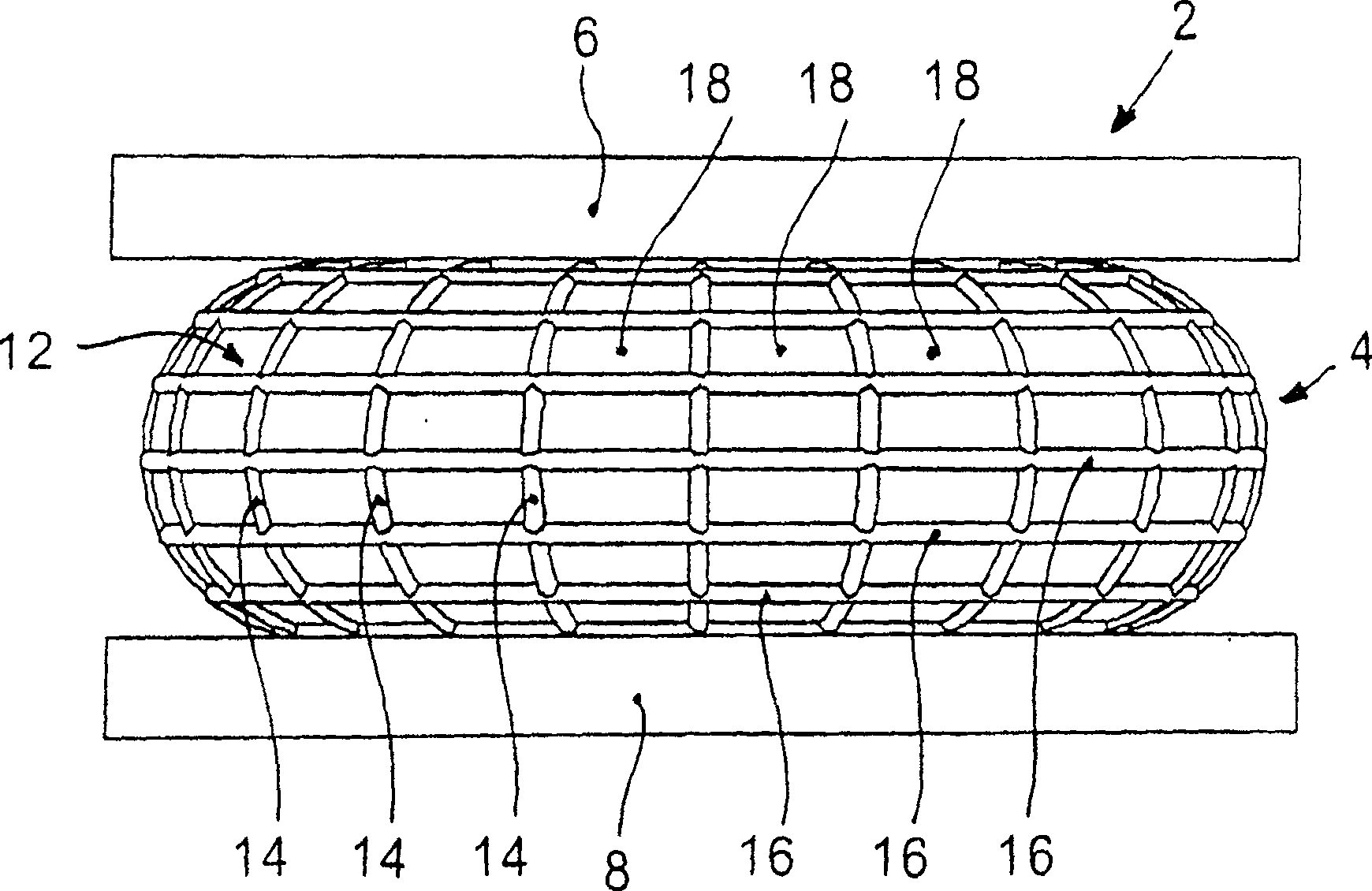

[0018] The spring element 2 shown in the figure is a so-called "leaf spring", which can be used both as a separate support spring and as an additional spring in combination with a pneumatic spring for supporting the bodywork of a rail vehicle.

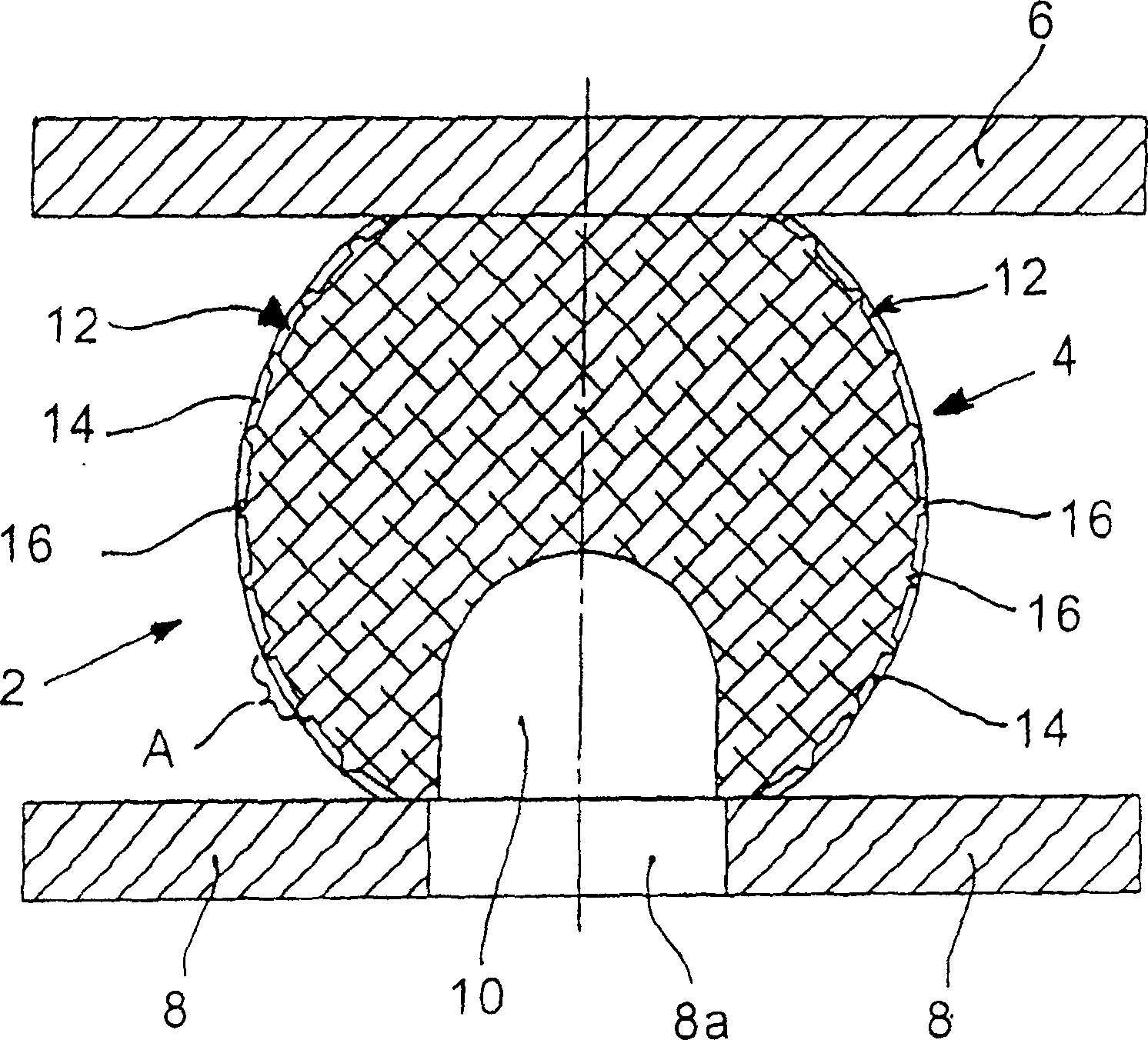

[0019] The spring element 2 is essentially formed by an elastic spring body 4 . It is fixed between two rigid end members 6 , 8 arranged at a variable distance from each other.

[0020] The spring body 4 has a rotationally symmetrical cross section. Longitudinal section ( figure 2 and Figure 4 ) represents a generally biconvex surface line. Owing to the cavity 10 overall a U-shaped longitudinal section results.

[0021] The spring body 4 is made of rubber or an elastic material with comparable elasticity.

[0022] Of the rigid end elements 6 , 8 , the "upper" element 6 is designed as a disc and the "lower" element 8 is designed as a ring. That is to say, the "lower" end piece 8 has a hole 8a in the middle, whereby the cavity 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com