General explosion-proof pressure-limit air valve for automobile tyre

A technology of automobile tires and nozzles, which is applied to tire inflation valves, tire parts, vehicle parts, etc., can solve the problems of inability to use gas nozzles, and achieve the effects of preventing tire blowout accidents, easy installation, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

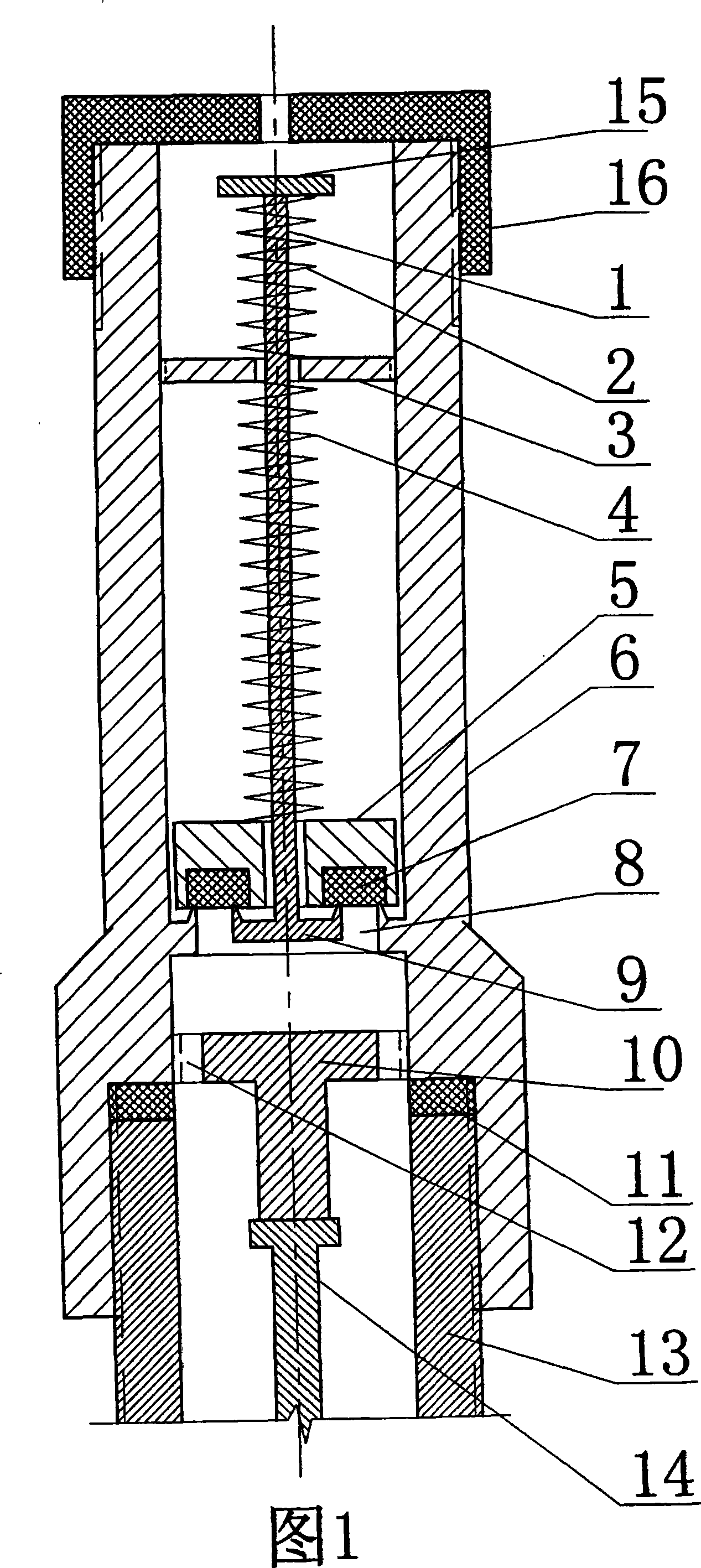

[0020] The present invention consists of pressure rod 1, inflatable spring 2, partition plate 3, compressed air spring 4, compressed air bowl 5, nozzle body 6, air sealing rubber ring 7, air hole 8, air sealing bowl 9, ejector rod 10, combined sealing ring 11. Ventilation hole 12, pressure reed 15 and mouth cap 16. The mouth body 6 is a cylindrical body with a partition inside. There is an air hole 8 on the inner partition. The air pressure bowl 5 is located above the air hole 8, and the air sealing rubber ring 7 is stuck in the annular groove at the bottom of the pressure bowl 5, the air seal bowl 9 is located in the air passage hole 8, the air seal bowl 9 is located at the lower end of the pressure rod 1 and is integrated with the pressure rod 1, and the pressure rod 1 is located between the pressure bowl 5 and the partition The through hole in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com