Nano wave-absorbing plastic material , and method for producing products made from the material

A technology of plastic materials and nano-materials, which is applied in the field of preparation of nano-absorbing composite plastic materials and their products, can solve problems such as poor performance, secondary electromagnetic pollution, and less absorption, and achieve high electromagnetic wave absorption rate, disease prevention, and major The effect of social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

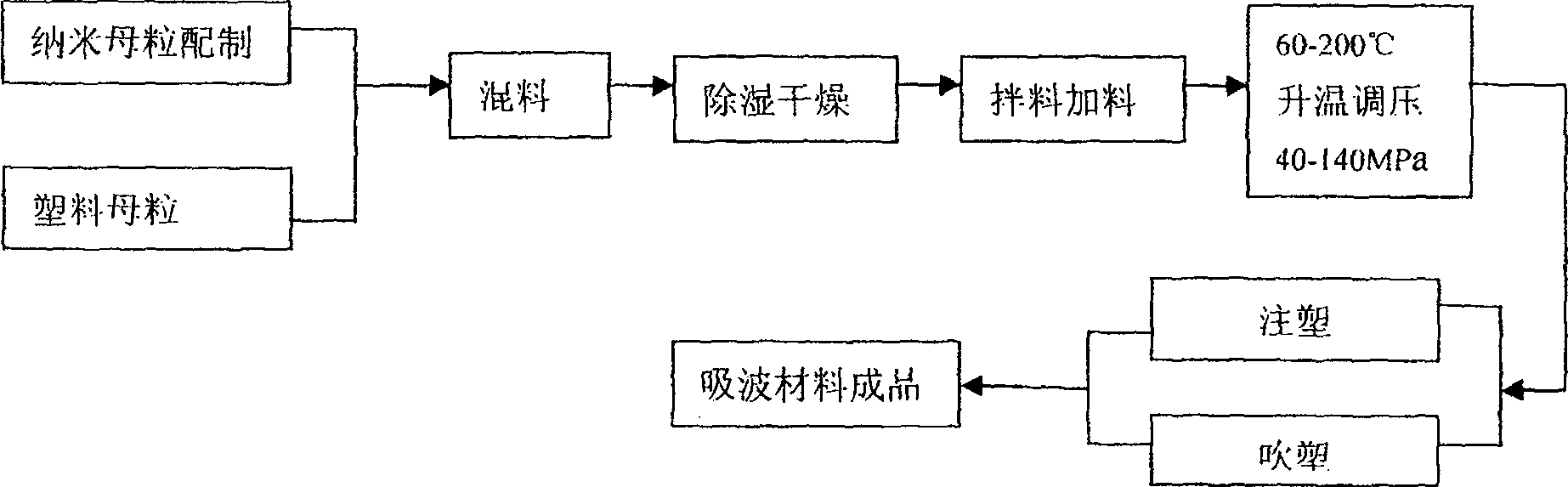

[0041] A preparation method of a nano wave-absorbing plastic material is carried out in the following steps:

[0042] a. Weigh the required weight of the plastic masterbatch according to the weight percentage and pour it into the mixer and stir evenly for later use;

[0043] b. Preparation of nano-masterbatch: Weigh the required weight of nano-β-silicon carbide, nano-nickel powder and liquid polyaniline according to the weight percentage and pour it into another mixer, ultrasonically oscillate evenly, dry and granulate for later use;

[0044] c. Take the required weight of the prepared nano-masterbatch and plastic masterbatch according to the weight percentage and pour it into the mixer and stir evenly. The mixing weight ratio is: nano-masterbatch: plastic masterbatch=1~2.8:1.3~ 5.6;

[0045] d. Dehumidification and drying;

[0046] e. Process flow

[0047] ①, nano masterbatch + plastic masterbatch mixing;

[0048] ②, 60 ℃ ~ 65 ℃ dehumidification and drying;

[0049] ③ St...

Embodiment 1

[0076] The nano wave-absorbing plastic material contains 58% of acrylonitrile-butadiene-styrene copolymer plastic masterbatch, 33% of nano-β-silicon carbide, 1% of nano-nickel powder, and 8% of polyaniline.

Embodiment 2

[0078] The method for preparing product is carried out successively according to the following steps:

[0079] a. Weigh the required weight of the plastic masterbatch according to the weight percentage and pour it into the mixer and stir evenly for later use;

[0080] b. Preparation of nano-masterbatch: Weigh the required weight of nano-β-silicon carbide, nano-nickel powder and liquid polyaniline according to the weight percentage and pour it into another mixer, ultrasonically oscillate evenly, dry and granulate for later use;

[0081] c. Take the required weight of the prepared nano-masterbatch and plastic masterbatch according to the weight percentage and pour it into the mixer and stir evenly. The mixing weight ratio is: nano-masterbatch: plastic masterbatch=1~2.8:1.3~ 5.6;

[0082] d. Dehumidification and drying;

[0083] e. Process flow

[0084] ①, nano masterbatch + plastic masterbatch mixing;

[0085] ②, 60 ℃ ~ 65 ℃ dehumidification and drying;

[0086] ③ Stir even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com