Pneumatic tire for heavy load

A technology for pneumatic tires and treads, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc., and can solve problems such as uneven wear of tire heels and tire toes

Inactive Publication Date: 2009-06-10

BRIDGESTONE CORP

View PDF10 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, in order to improve the wet performance, if the sipes are provided approximately along the tire width direction in the entire area of the rib sandwiched by the grooves in the circumferential direction, there will be a problem of uneven wear of the heel and toe from there, and it must be difficult to achieve Coexistence of wet performance and uneven wear resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0062] The present invention will be described below based on examples.

[0063] The heavy-duty pneumatic tires of the first and second embodiments were implemented under the following conditions Image 6 A test for comparative evaluation of a heavy-duty pneumatic tire (conventional example) of the conventional example shown.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

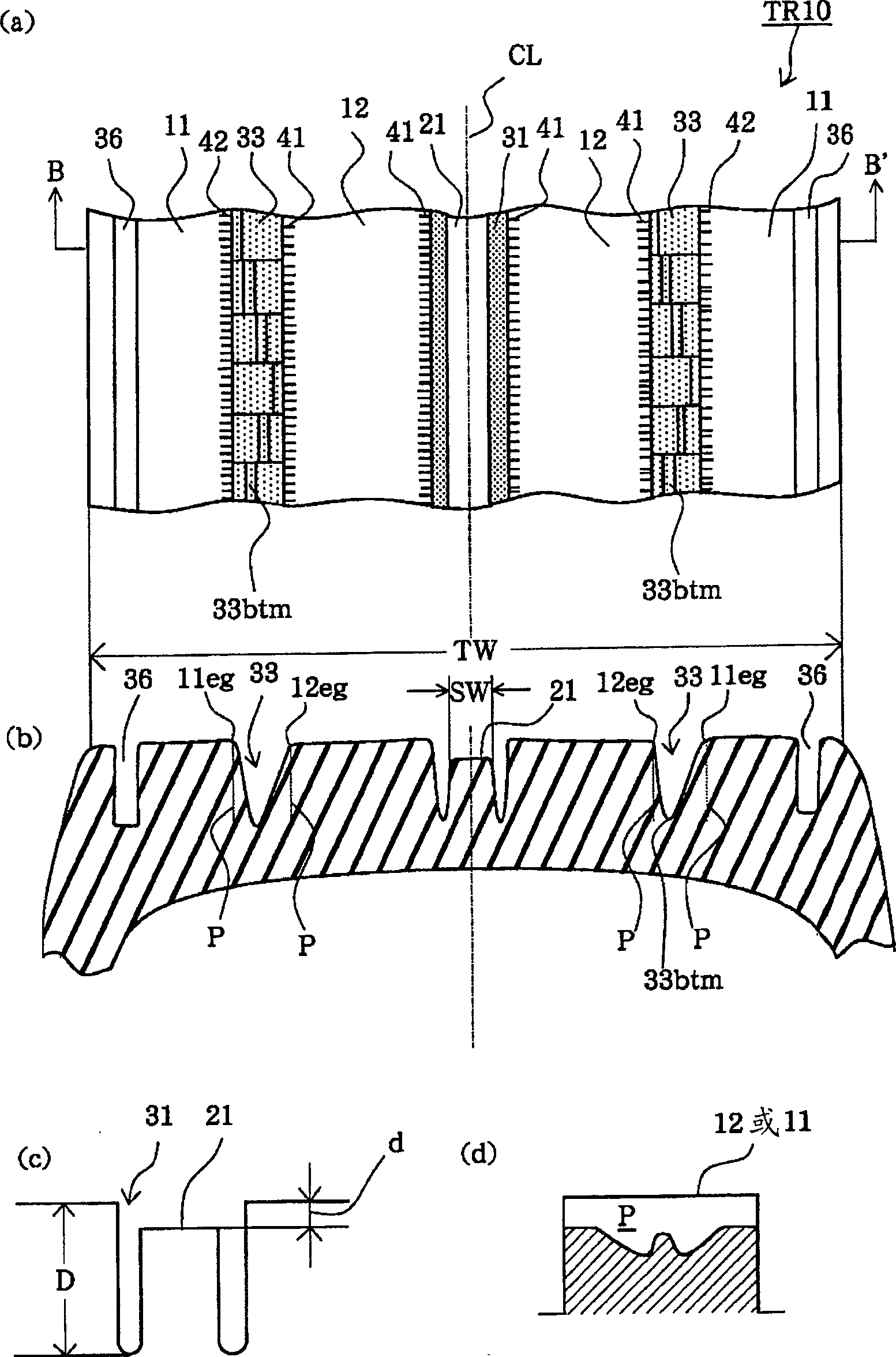

A pneumatic tire for heavy load enabling the co-existence of wet performance and uneven wear resistance performance is provided. The pneumatic tire for heavy load includes three circumferential main grooves 31 and 33 extending on a tread in the circumferential direction, and ribs 11 and 12 defined by these circumferential main grooves 31 and 33. The centerline of the center circumferential main grove 31 among the three circumferential main grooves is positioned on the equator line of the tread, and a thin rib-shaped uneven abrasion sacrificing part (BCR) 21 having a step in a clearance thereof from the surface of the tread is formed only in the center circumferential main groove 31.

Description

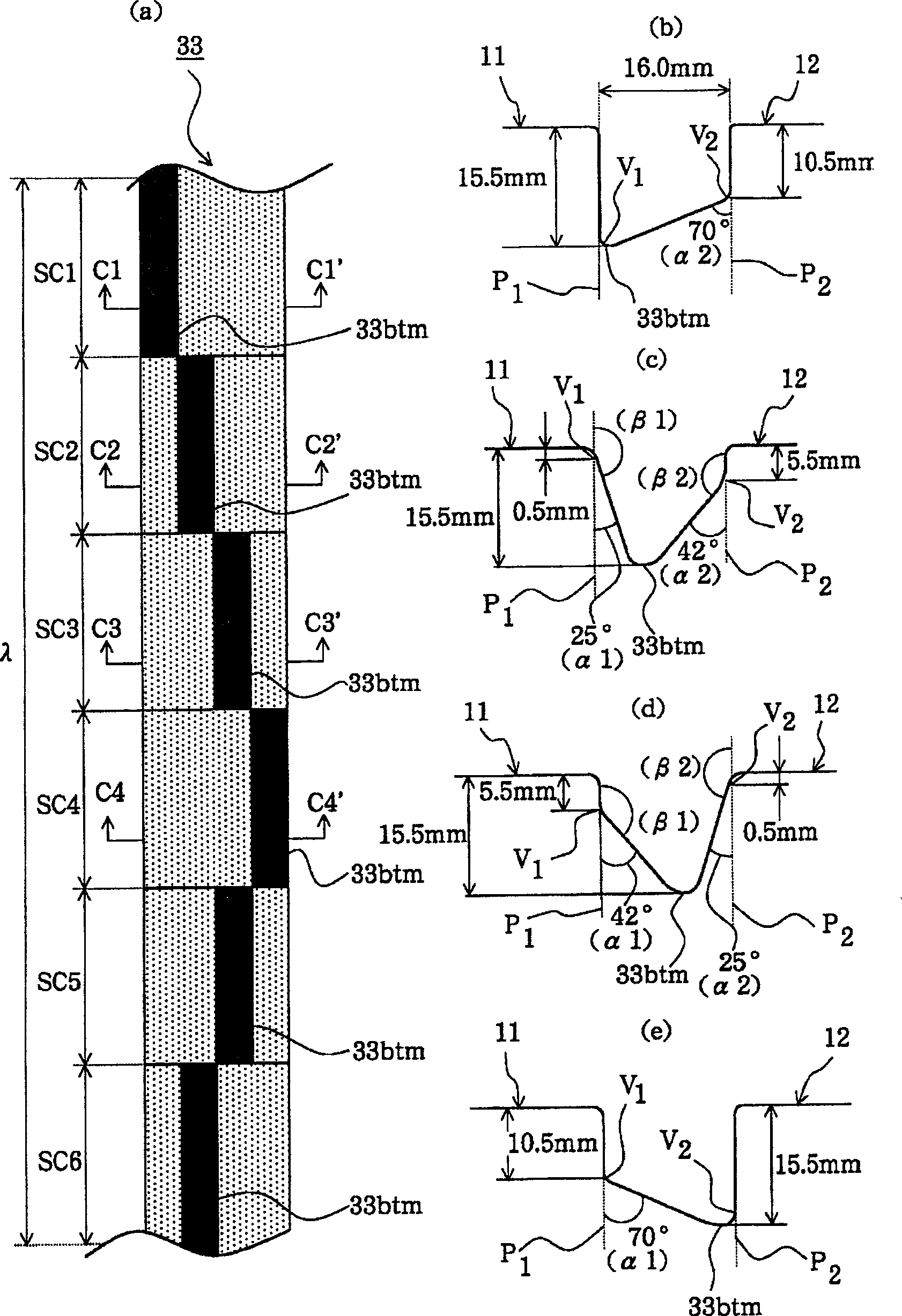

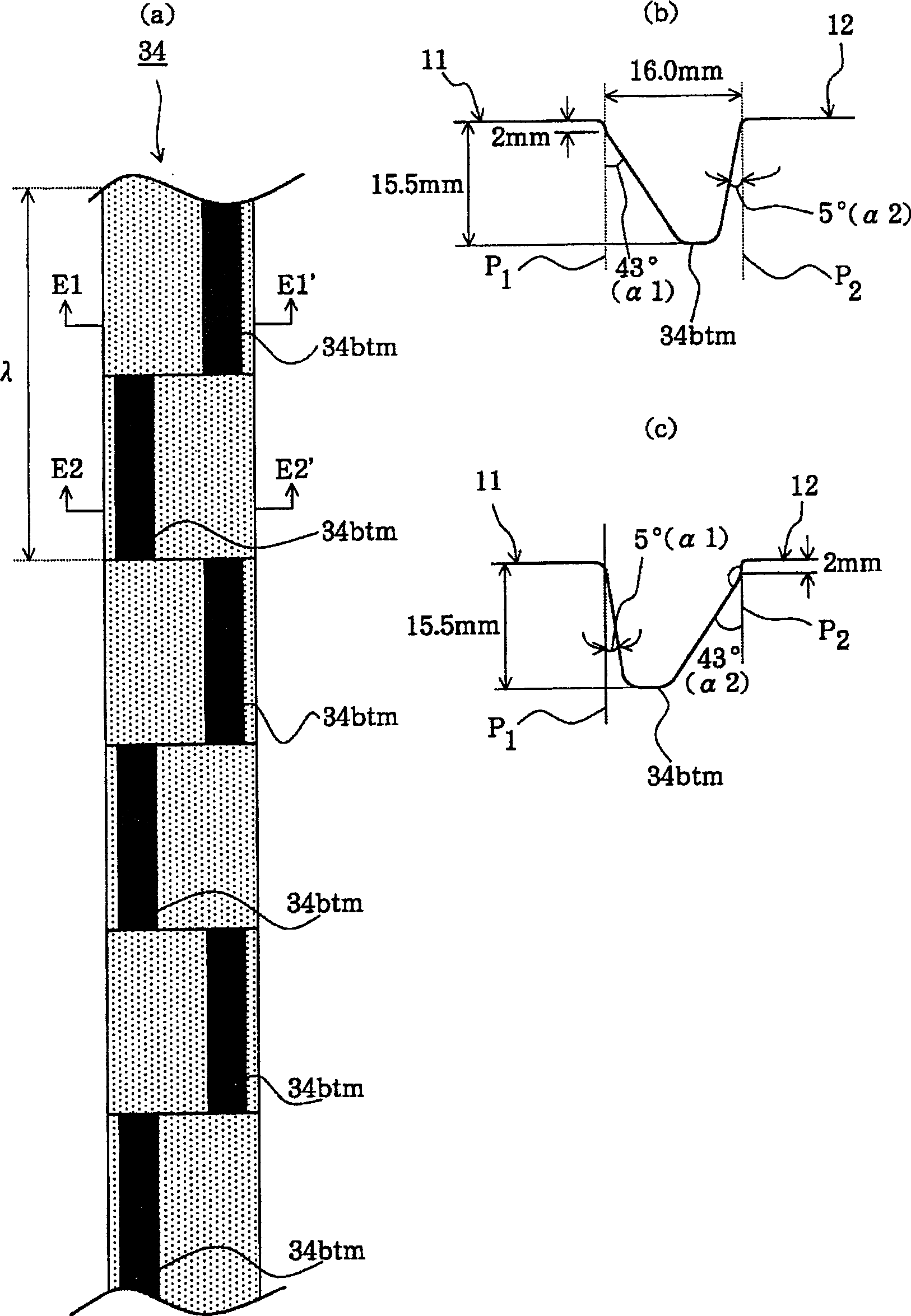

technical field [0001] The present invention relates to a pneumatic tire, in particular, to a heavy-duty pneumatic tire that achieves both uneven wear resistance and drainage performance by improving the tread pattern. Background technique [0002] Conventionally, in order to suppress uneven wear of shoulder ribs in heavy-duty pneumatic tires, a method has been widely used: forming a narrow rib-shaped uneven wear sacrificial sacrifice with a drop from the tread in the main grooves in the circumferential direction. (hereinafter abbreviated as "BCR"), the shear force in the running direction of the edge portion of the shoulder rib body is reduced by generating a shear force in the tread opposite to the running direction of the vehicle by the BCR (refer to the Japanese special Kaihei 2-88311 Bulletin). [0003] here, Image 6 (a) shows a partial plan development view of a heavy duty pneumatic tire tread having a BCR. also, Image 6 (b) yes Image 6 A cross-sectional view of t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B60C11/04B60C11/14B60C11/03

CPCY10S152/901Y10S152/03Y10S152/01B60C11/047B60C11/042B60C11/045B60C11/1315

Inventor 富田明

Owner BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com