Compound alkali metal hydrate dissolvent synthesis method for metallic sulfide nano crystal material

A metal sulfide and nanocrystal technology, applied in the direction of alkali metal sulfide/polysulfide, etc., to achieve the effect of less controllable parameters and low synthesis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

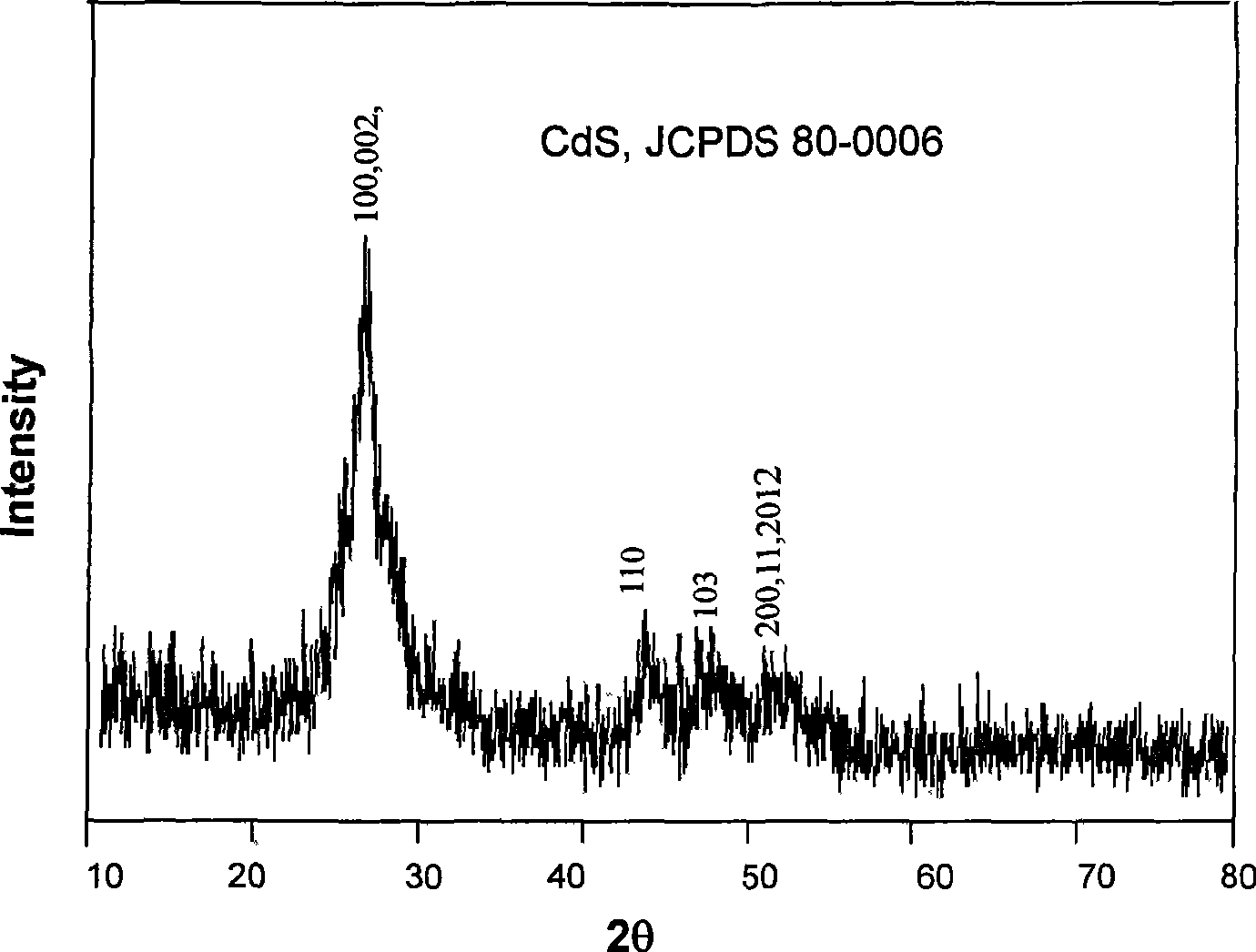

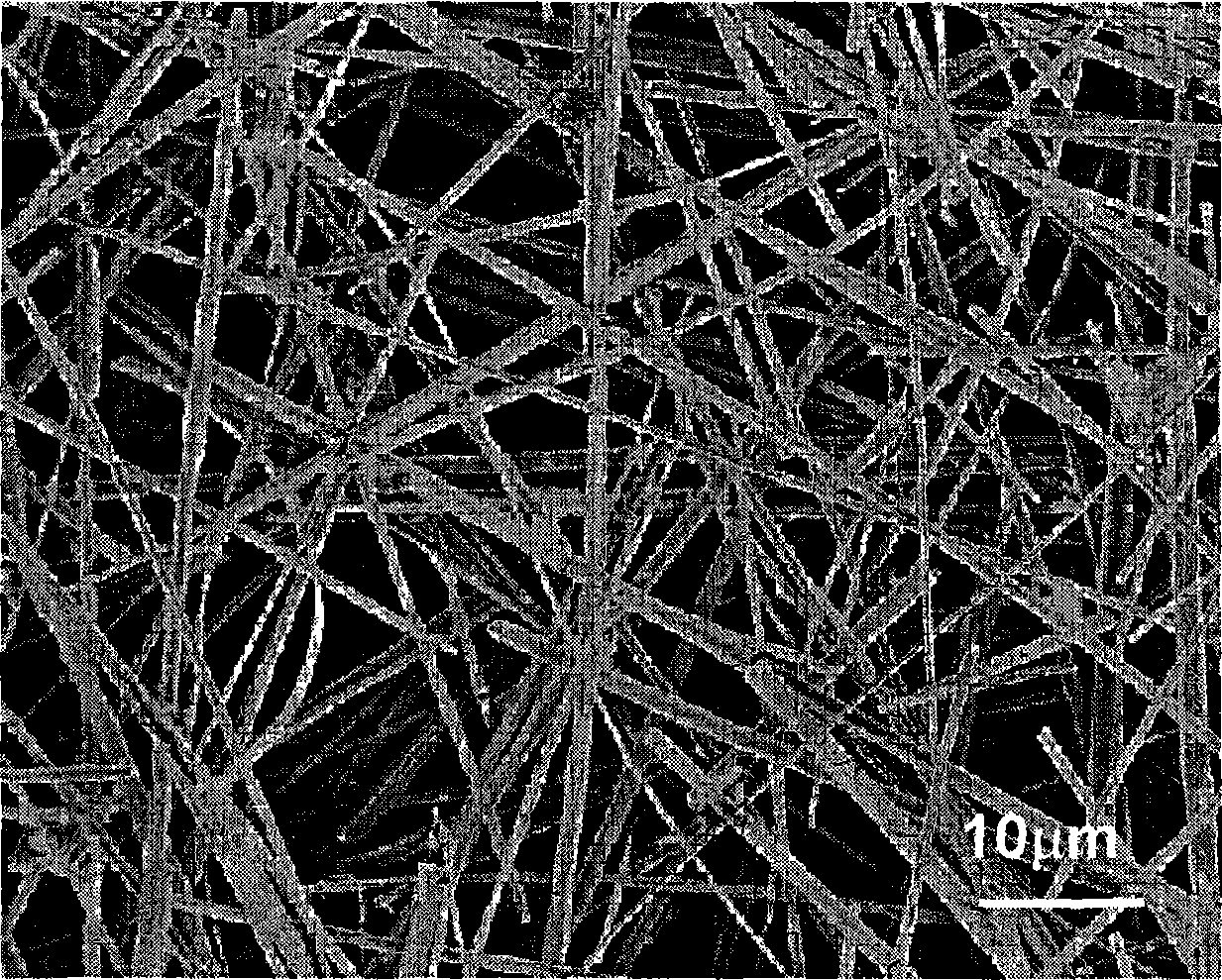

[0026] The specific synthetic method of cadmium sulfide (CdS) nanocrystal material

[0027] 1. KOH=57% and NaOH=43% are weighed and mixed as the reaction solvent according to weight percentage.

[0028] 2. According to cadmium chloride (CdCl 2 ) and the weight percent of sulfur powder are respectively 23% and 77% weighing as reactant. The weight percent of reactants to reactants+reaction solvent was 2.2%.

[0029] 3. Put the reaction raw materials in the above step 2 and the reaction solvent in the above step 1 into a polytetrafluoroethylene reaction container, then seal the polytetrafluoroethylene container and place it in a constant temperature muffle furnace with a temperature of 200°C. After the reaction vessel is kept warm in the furnace for 40 minutes, the reaction vessel is opened and stirred to uniformly mix the molten reaction solvent and the reactants. The reaction vessel was sealed again with a cover, and kept at a constant temperature of 200° C. for 24 hours.

...

Embodiment 2

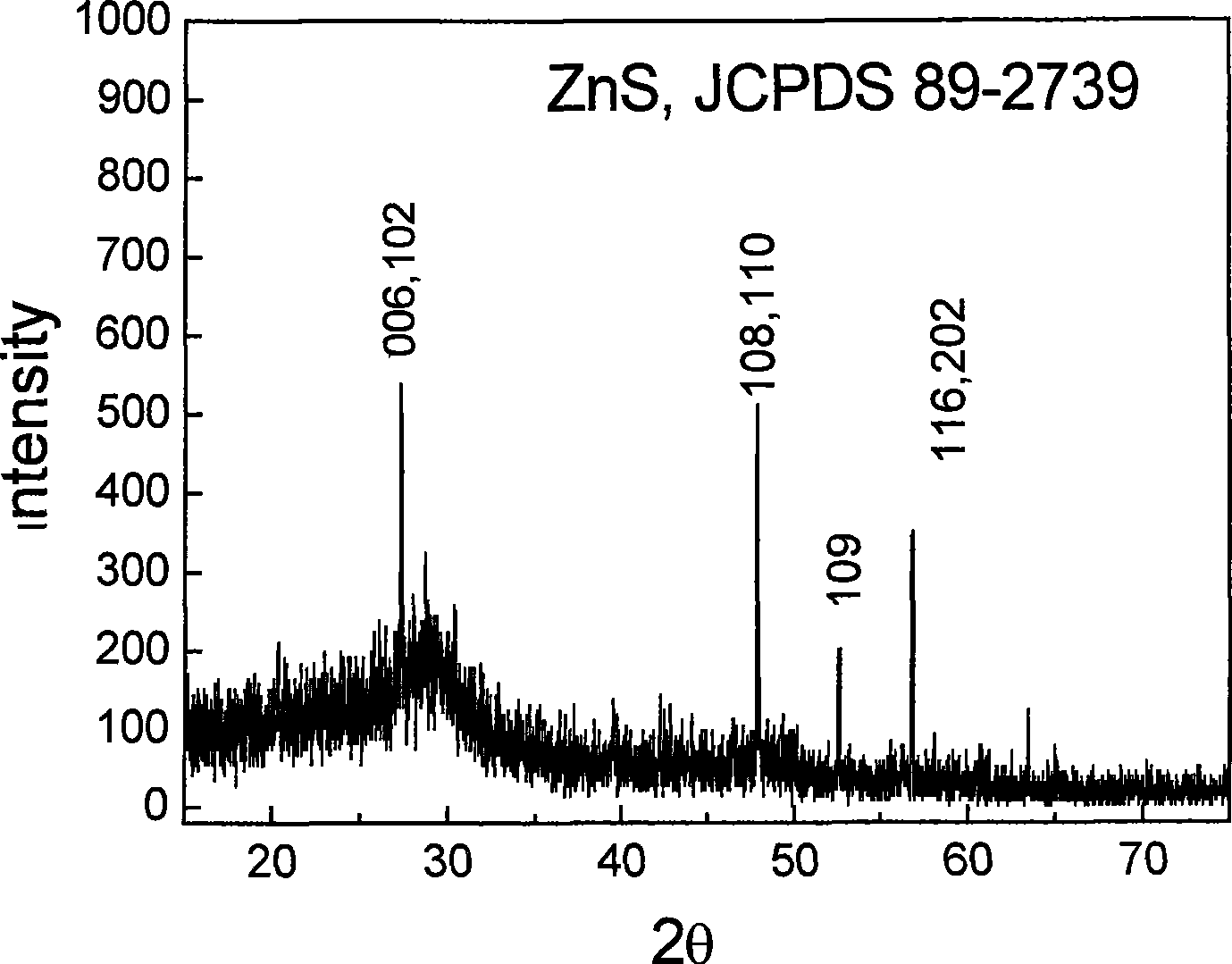

[0034] Synthesis of Zinc Sulfide (ZnS) Nanocrystalline Structure

[0035] 1. Weigh and mix KOH=57% and NaOH=43% by weight as the reaction solvent.

[0036] 2. According to zinc acetate (Zn(CH 3 COO) 2· 2H 2 O) and sodium sulfide (Na 2 S.9H 2 O) weight percentages of 16% and 84% were weighed as reactants. The weight percentage of reactant to reactant+reaction solvent is 10%.

[0037] 3. Put the reaction raw materials in the above step 2 and the reaction solvent in the above step 1 into a polytetrafluoroethylene reaction container, then seal the polytetrafluoroethylene container and place it in a constant temperature muffle furnace with a temperature of 200°C. After the reaction vessel is kept warm in the furnace for 40 minutes, the reaction vessel is opened and stirred to uniformly mix the molten reaction solvent and the reactants. The reaction vessel was capped again and kept at a constant temperature of 200° C. for 41 hours.

[0038] 4. Take the reaction vessel out of...

Embodiment 3

[0042] Synthetic method of lead sulfide (PbS) nanocrystal material

[0043] 1. Weigh and mix KOH=57% and NaOH=43% by weight as the reaction solvent.

[0044] 2. According to lead nitrate (Pb(NO 3 ) 2 ) and sodium sulfide (Na 2 S.9H 2 O) weight percentages of 42% and 58% were weighed as reactants. The weight percent of reactants to reactants+reaction solvent was 1.3%.

[0045] 3. Put the reaction raw materials in the above step 2 and the reaction solvent in the above step 1 into a polytetrafluoroethylene reaction container, then seal the polytetrafluoroethylene container and place it in a constant temperature muffle furnace with a temperature of 165°C. After the reaction vessel is kept warm in the furnace for 40 minutes, the reaction vessel is opened and stirred to uniformly mix the molten reaction solvent and the reactants. The reaction vessel was sealed again with a cover, and kept at a constant temperature of 165° C. for 12 hours.

[0046] 4. Take the reaction vessel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com