Process for producting petruleum resin by hot polymerizing

A petroleum resin and thermal polymerization technology, applied in the field of thermal polymerization to produce petroleum resin, can solve the problems affecting product quality and chromaticity, the influence of thermal polymerization petroleum resin product application scope, and the high kettle temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

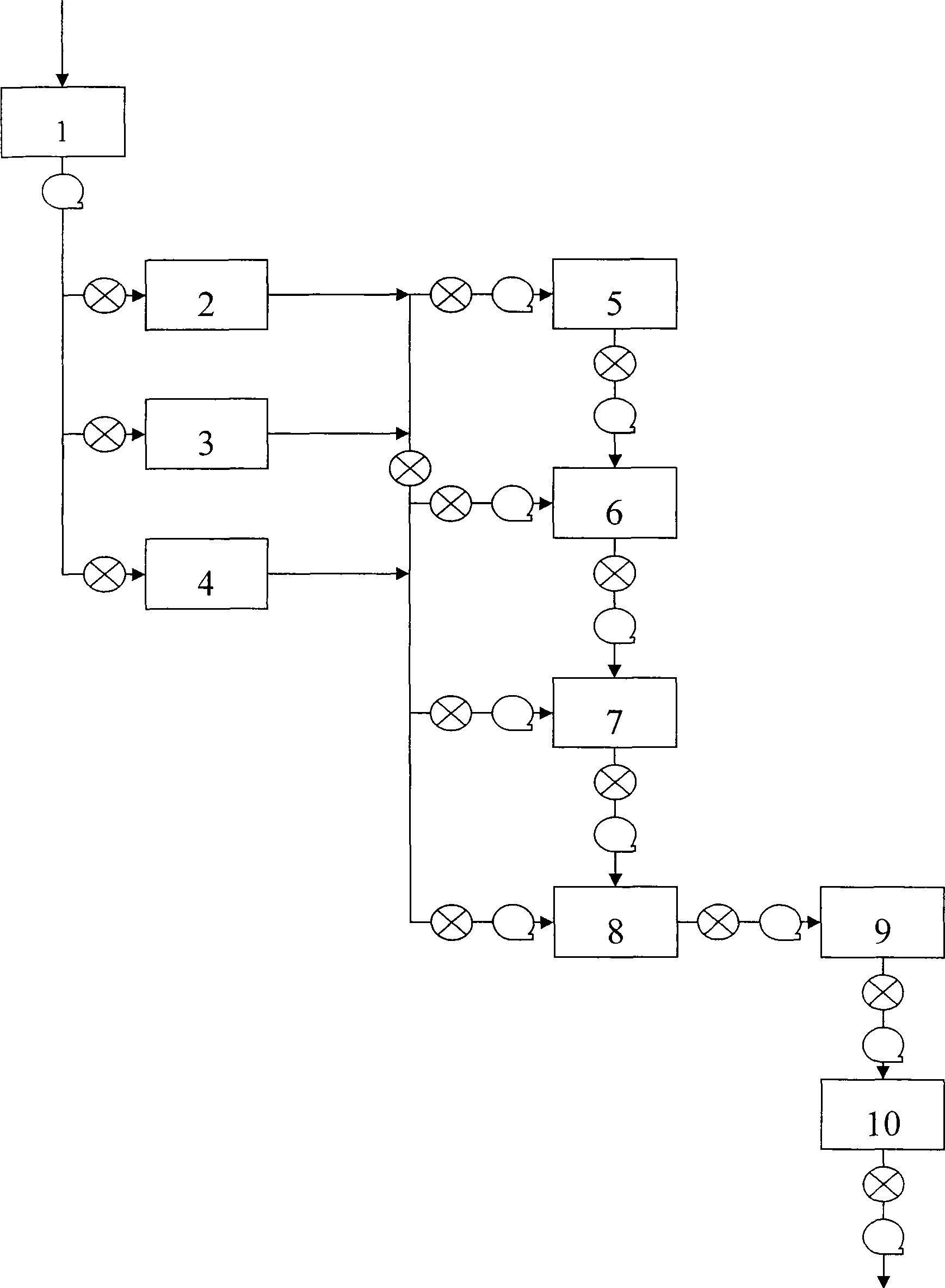

[0022] See attached figure 1 , the I, II, and III obtained by distillation of the C9 raw material are all passed into the thermal polymerization kettle 1 (5), the temperature of the reactor 1 is controlled at 240°C, the pressure is 0.5MPa, and the residence time is 6h; the material in the thermal polymerization kettle 1 enters the thermal polymerization kettle 2(6), control the temperature of thermal polymerization kettle 2 to 250°C, pressure 1.0MPa, and residence time 6h; the material in thermal polymerization kettle 2 enters thermal polymerization kettle 3(7), control the temperature of thermal polymerization kettle 3 to 260°C, and pressure 1.5MPa , the residence time is 6h; the material in the thermal polymerization kettle 3 enters the thermal polymerization kettle 4 (8), and the temperature of the thermal polymerization kettle 4 is controlled at 280°C, the pressure is 2.1MPa, and the residence time is 6h. The material that comes out from thermal polymerization kettle 4 ent...

Embodiment 2

[0024] See attached figure 1, put I and III into the thermal polymerization kettle 1 (5), II into the thermal polymerization kettle 4 (6), control the temperature of the thermal polymerization kettle 1 at 210°C, the pressure of 0.2MPa, and the residence time of 4h; the material in the thermal polymerization kettle 1 Enter thermal polymerization kettle 2 (6), control thermal polymerization kettle 2 temperature 220°C, pressure 0.5MPa, residence time 4h; material in thermal polymerization kettle 2 enters thermal polymerization kettle 3 (7), control thermal polymerization kettle 3 temperature 230°C , pressure 0.8MPa, residence time 4h; material in thermal polymerization kettle 3 enters thermal polymerization kettle 4 (8), controls temperature of thermal polymerization kettle 4 to 230°C, pressure 1.0MPa, residence time 4h. The material coming out from the thermal polymerization kettle 4 enters the secondary falling film evaporator, falling film evaporator 1 (9) temperature 115 ° C,...

Embodiment 3

[0026] See attached figure 1 , pass I, III into thermal polymerization kettle 1 (5), and add the peracetic acid of raw material amount 0.01% in thermal polymerization kettle 1 as initiator, II pass into thermal polymerization kettle 3 (7), control thermal polymerization kettle 1 The temperature is 230°C, the pressure is 0.3MPa, and the residence time is 5h; the material in the thermal polymerization kettle 1 enters the thermal polymerization kettle 2 (6), and the temperature of the thermal polymerization kettle 2 is controlled at 240°C, the pressure is 0.8MPa, and the residence time is 5h; the thermal polymerization kettle 2 The material in the thermal polymerization kettle 3 (7), the temperature of the thermal polymerization kettle 3 is controlled at 250 ° C, the pressure is 1.2 MPa, and the residence time is 5h; the material in the thermal polymerization kettle 3 enters the thermal polymerization kettle 4 (8), and the thermal polymerization kettle 4 is controlled. The temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com