Electromagnetic fuel injection valve

A fuel injection valve, electromagnetic technology, applied in the direction of fuel injection device, charging system, machine/engine, etc., can solve the problem of poor initial running-in condition of the inner surface of the guide hole, change of fuel flow characteristics, and easy change of sliding surface width, etc. problem, to achieve the effect of good responsiveness, reduced wear and good flow characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

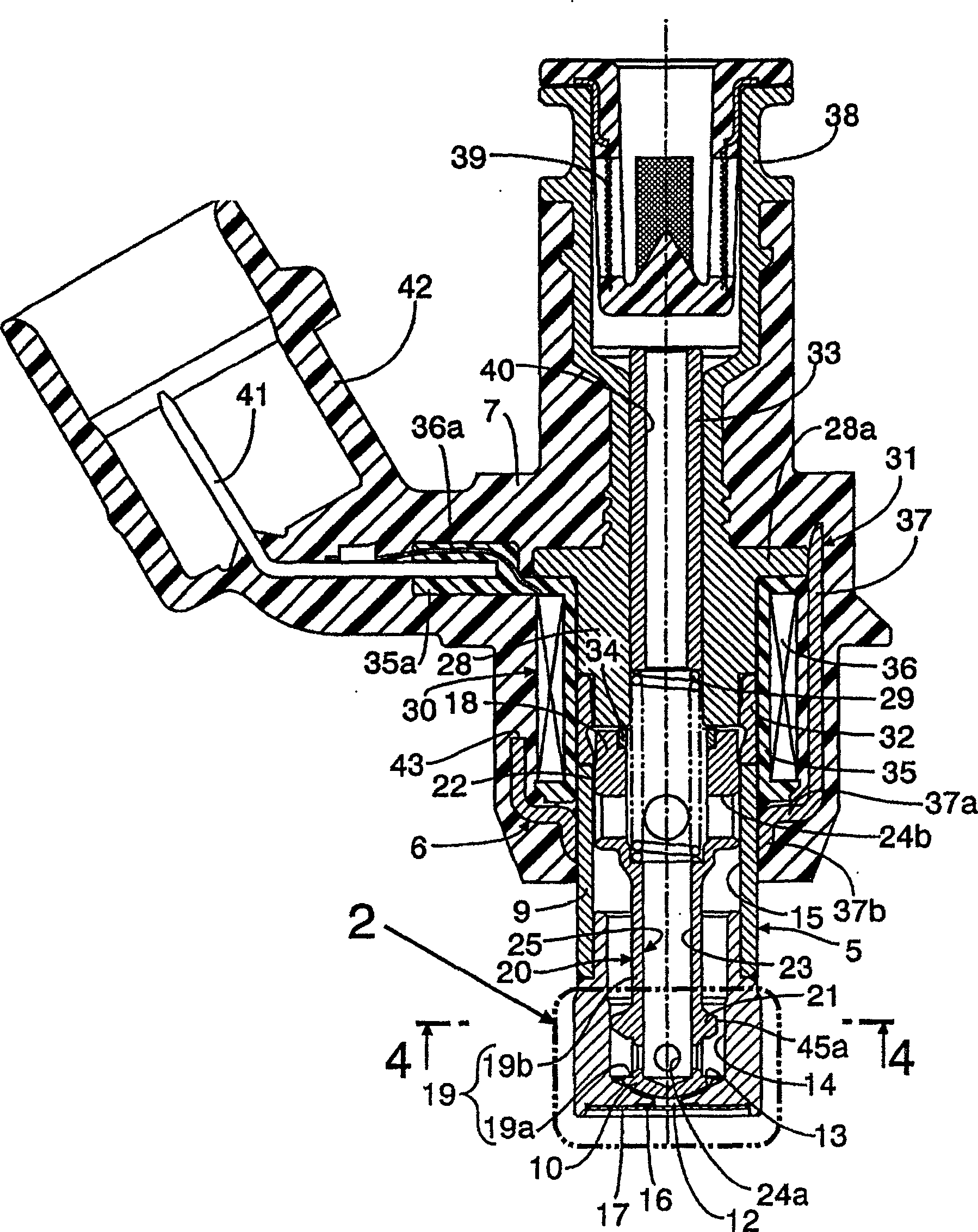

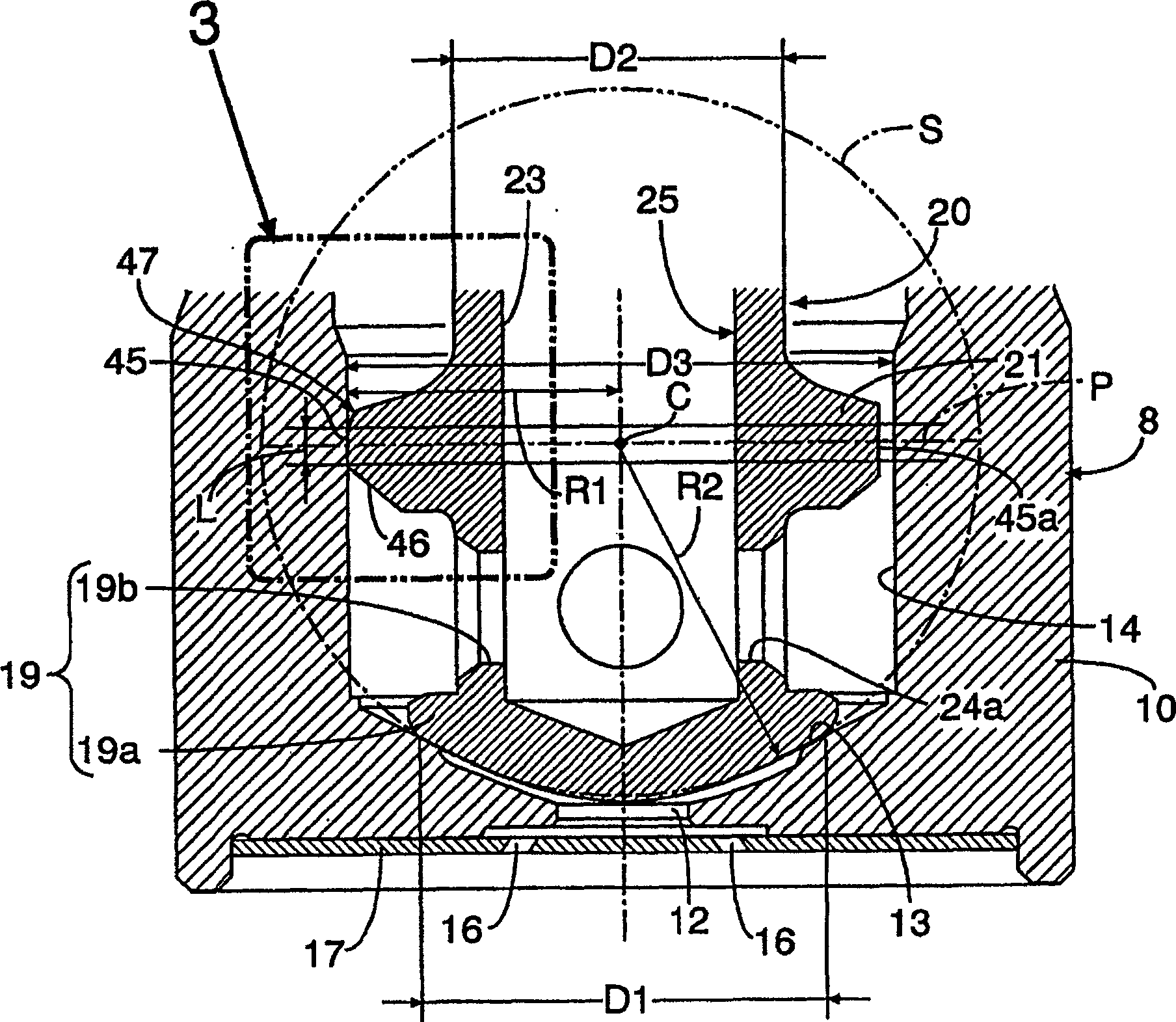

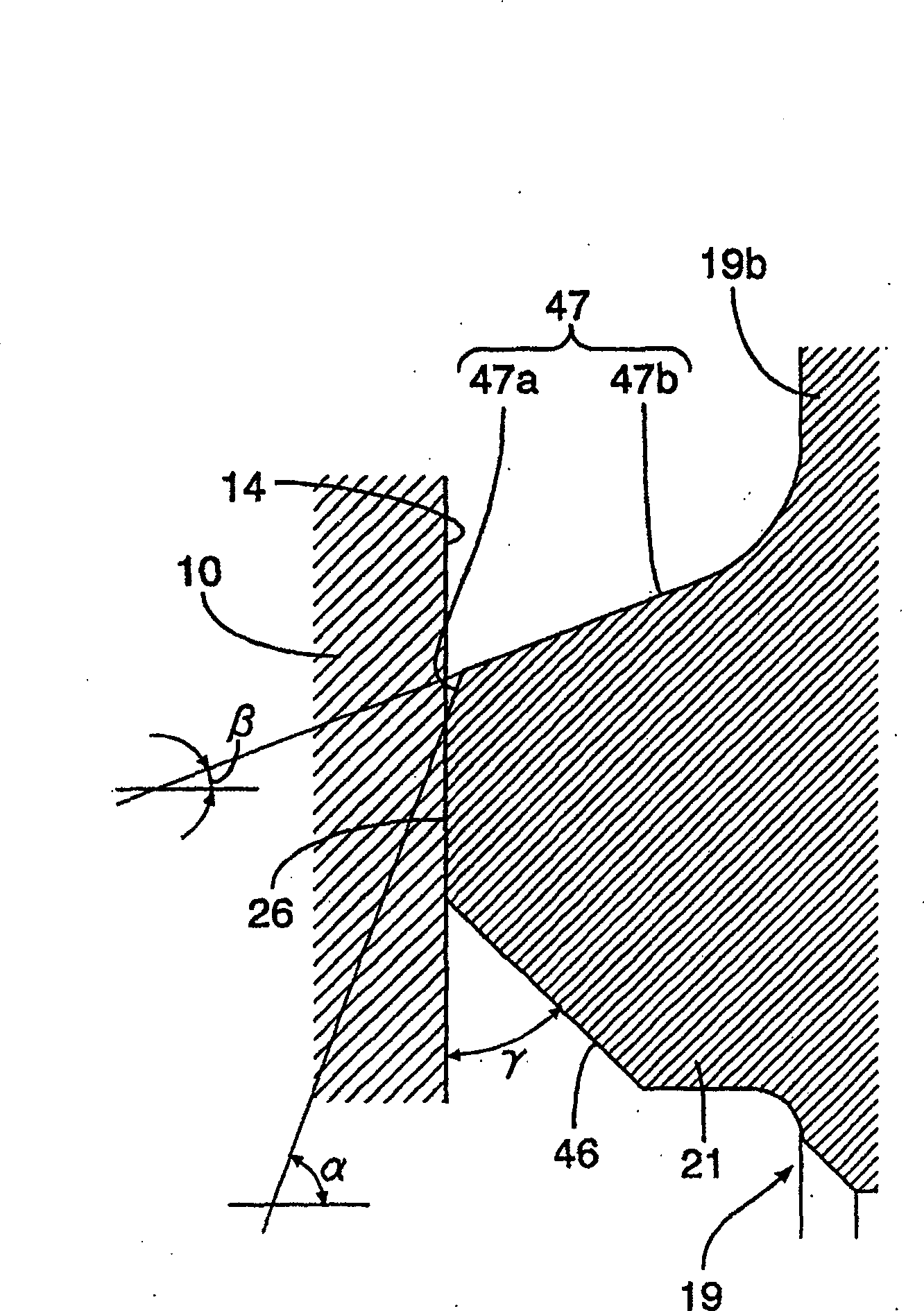

[0043] Hereinafter, an embodiment of the present invention will be described based on an embodiment of the present invention shown in the drawings.

[0044] Figure 1 to Figure 4 One embodiment of the invention is shown.

[0045] first,figure 1 Among them, an electromagnetic fuel injection valve for injecting fuel into an unillustrated engine has a valve operating part 5 that accommodates a valve assembly 20 in a valve sleeve 8 having a valve seat 13 at the front end thereof. The valve assembly 20 receives spring force in the direction of seating on the valve seat 13; the solenoid part 6, the solenoid part 6 accommodates the coil assembly 30 in the solenoid sleeve 31 connected to the valve sleeve 8 Inside, the coil assembly 30 can generate electromagnetic force to drive the valve assembly 20 to the side away from the valve seat 13; the covering part 7, the covering part 7 is made of synthetic resin, and integrally has a connection The connecting terminal 41 ... the exposed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com