Method for setting up a warp knitting machine

A technology for start-up, warp knitting machines, applied in warp knitting, textile and papermaking, knitting, etc., capable of solving problems such as rising, first and second needle collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

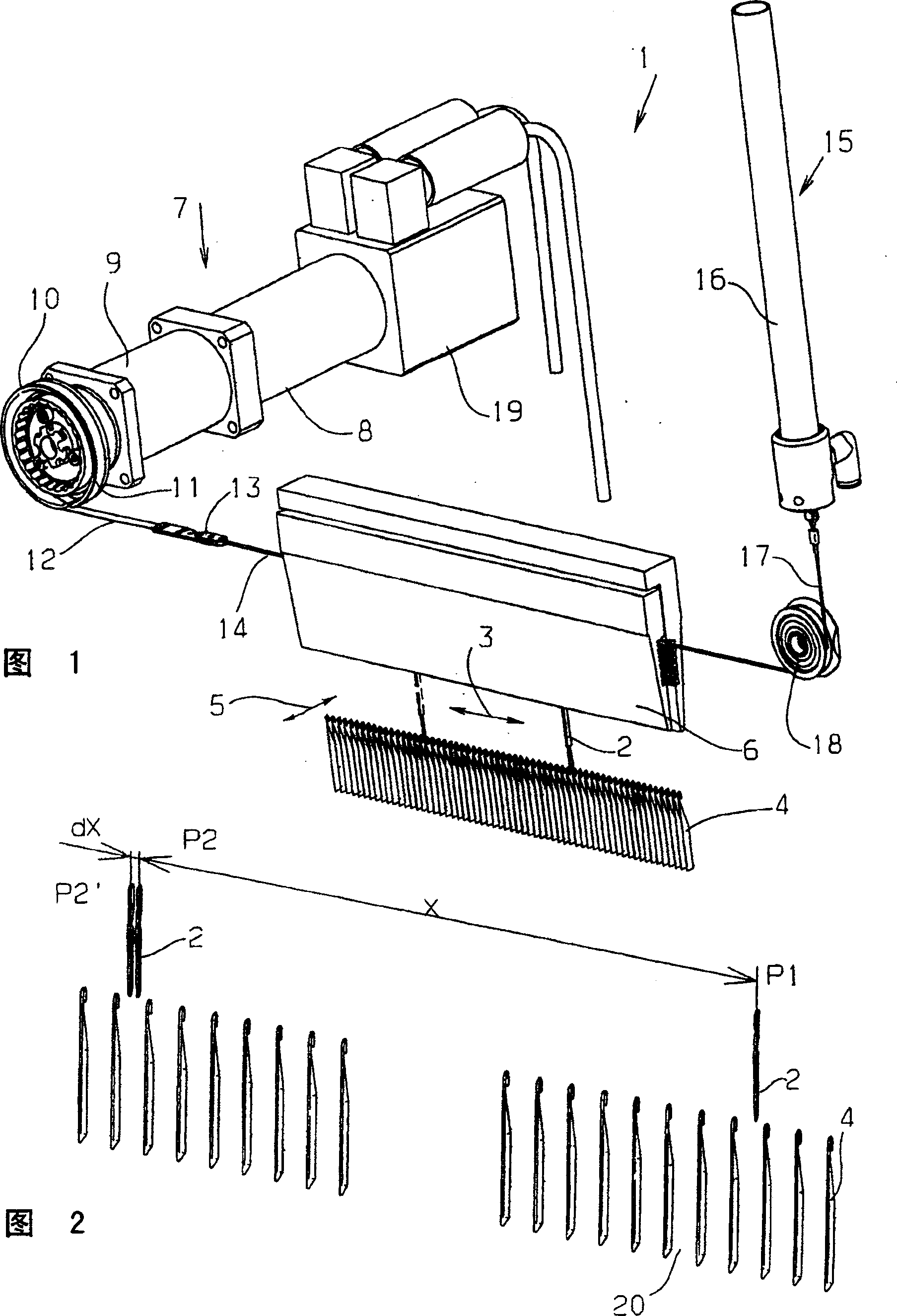

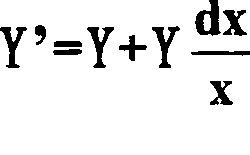

[0023] The warp knitting machine 1 shown only schematically in a partial view in FIG. 1 has first needles 2 , for example guide needles, which can counteract second needles 4 , for example crochet needles, in the traverse direction 3 . traverse. After the end of the movement in the traversing direction 3, the first needle 2 and the second needle 4 can also be moved relative to each other in the direction of the double arrow 5 in order to end the stitching process. In this case, the first needle 2 is generally moved relative to the second needle 4 .

[0024] In order to be able to move all first needles 2 identically, first needles 2 are fastened to a bar 14 which is guided in a guide 6 . A plurality of slots for the bars 14 are provided in the guide 6 . For reasons of clarity, however, only one bar 14 is shown. In practice the bar 14 generally carries more first needles than are shown in the different positions. The guide 6 essentially extends over the working width of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com