Light hydraulic support for cannon sampled thin coal layer

A technology of hydraulic support and thin coal seam, which is applied in the direction of mine roof support, mining equipment, earthwork drilling, etc., to achieve the effect of reducing the weight of the whole frame, facilitating installation and operation, and reducing the thickness of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

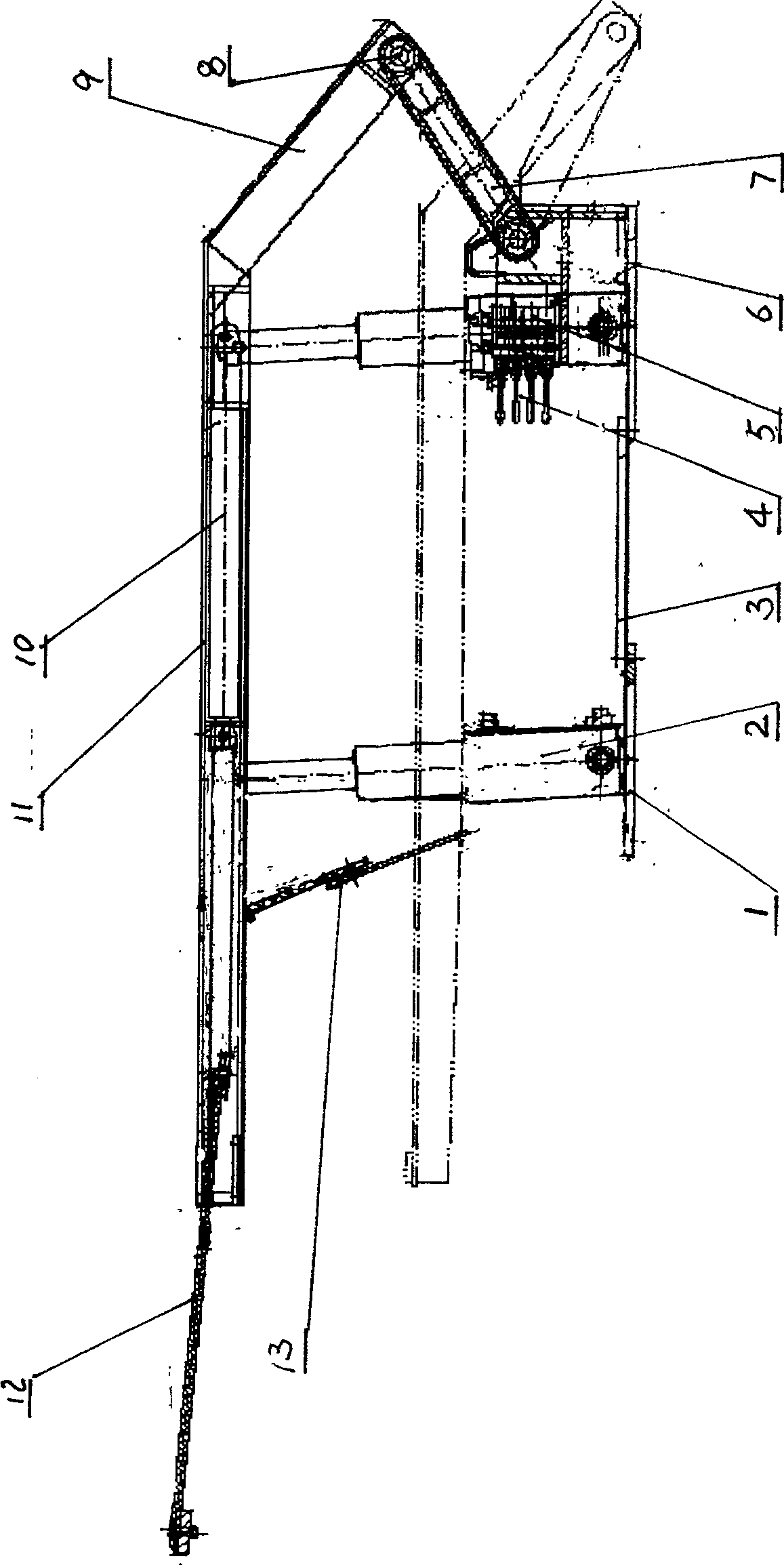

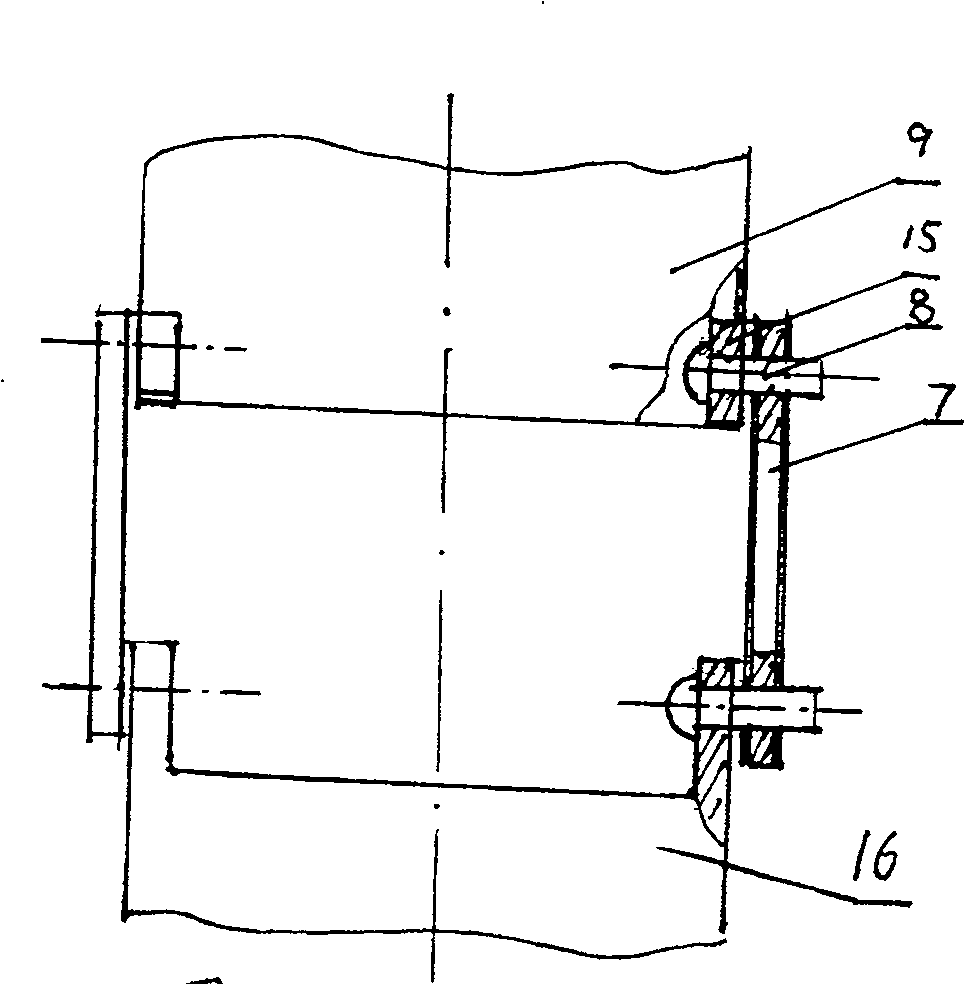

[0017] from figure 1 , figure 2 and image 3 It can be seen that the present invention includes a base on which four front and rear hydraulic props 2 and 5 are installed, and the four hydraulic props 2 and 5 are connected to support the box top beam 11 and the hydraulic operating system 4 . in:

[0018] 1. The structure of the base is a split assembly structure, that is, it is divided into a front chassis 1 and a rear chassis 6. The front chassis 1 is equipped with two left and right hydraulic props 2, and the rear chassis 6 is equipped with left and right hydraulic props 5. The front and rear chassis 1 and 6 are connected into one body with spring steel plate 3.

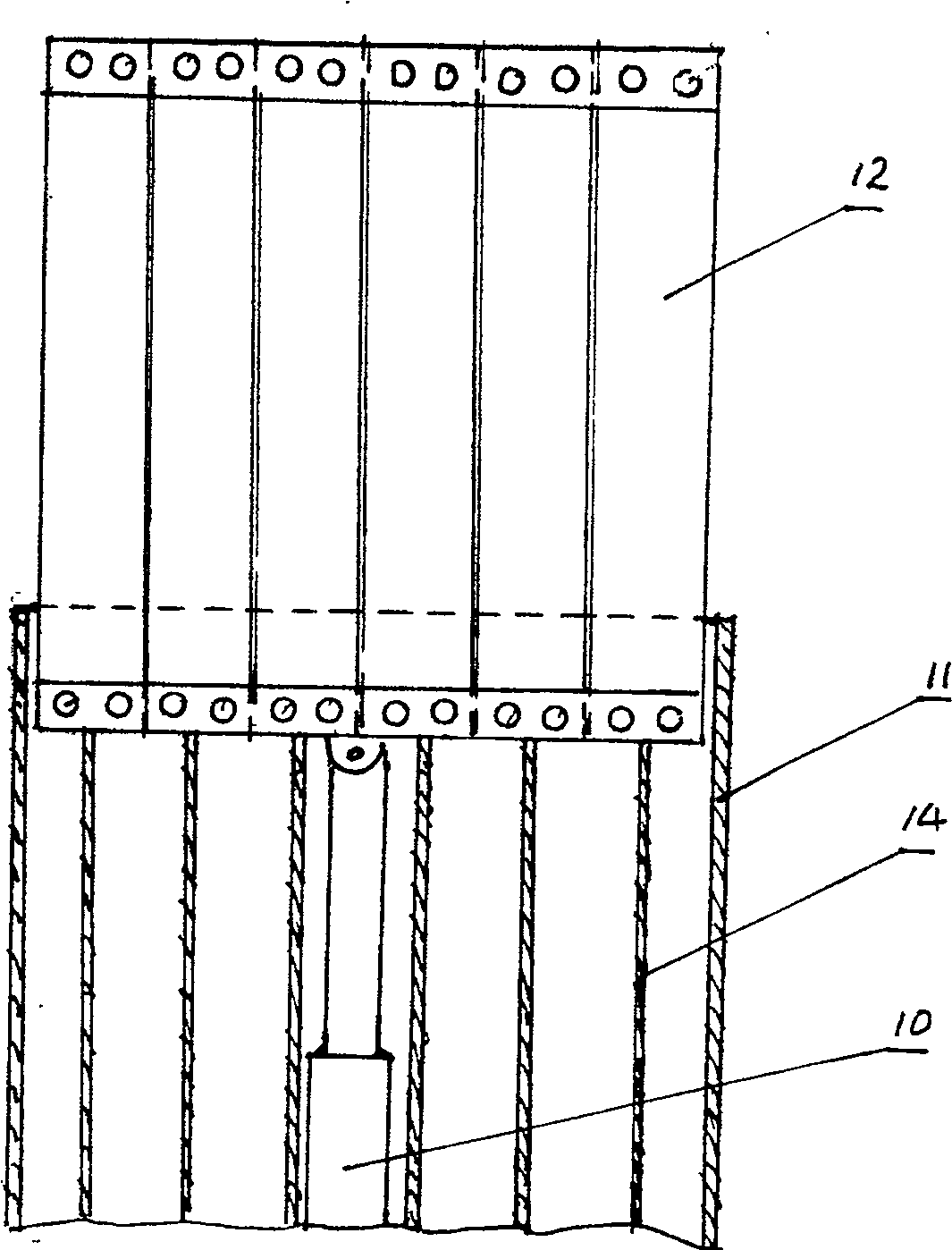

[0019] 2. A box-type roof beam is connected to the top of the four hydraulic pillars. The box-type roof beam 11 is a reinforced box structure, which is welded by upper and lower two-layer steel plates, and reinforcing ribs 14 are welded between the steel plates to improve the overall strength. A jack 10 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com