Large-sized low-speed heavy-loaded gear box fault diagnosis method

A low-speed, heavy-duty, fault diagnosis technology, applied in machine gear/transmission mechanism testing, mechanical component testing, machine/structural component testing, etc., can solve problems such as problems that cannot be effectively solved for large-scale low-speed heavy-duty gearbox diagnosis , to achieve the effect of improving the fault diagnosis rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049]Provide following embodiment in conjunction with the content of the inventive method:

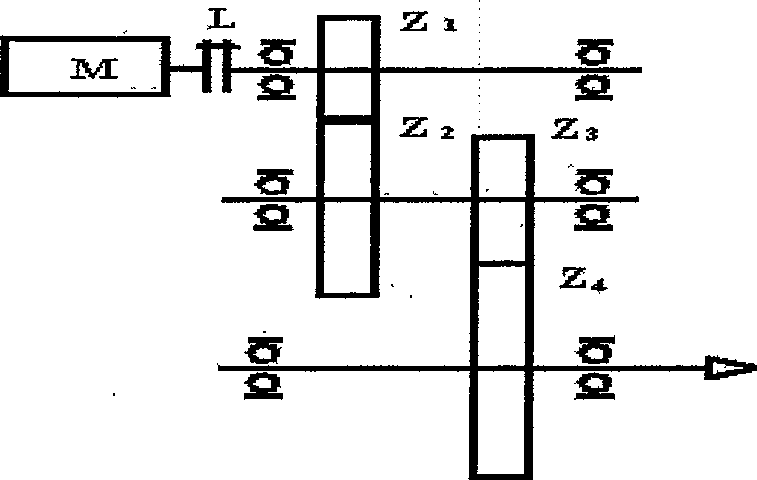

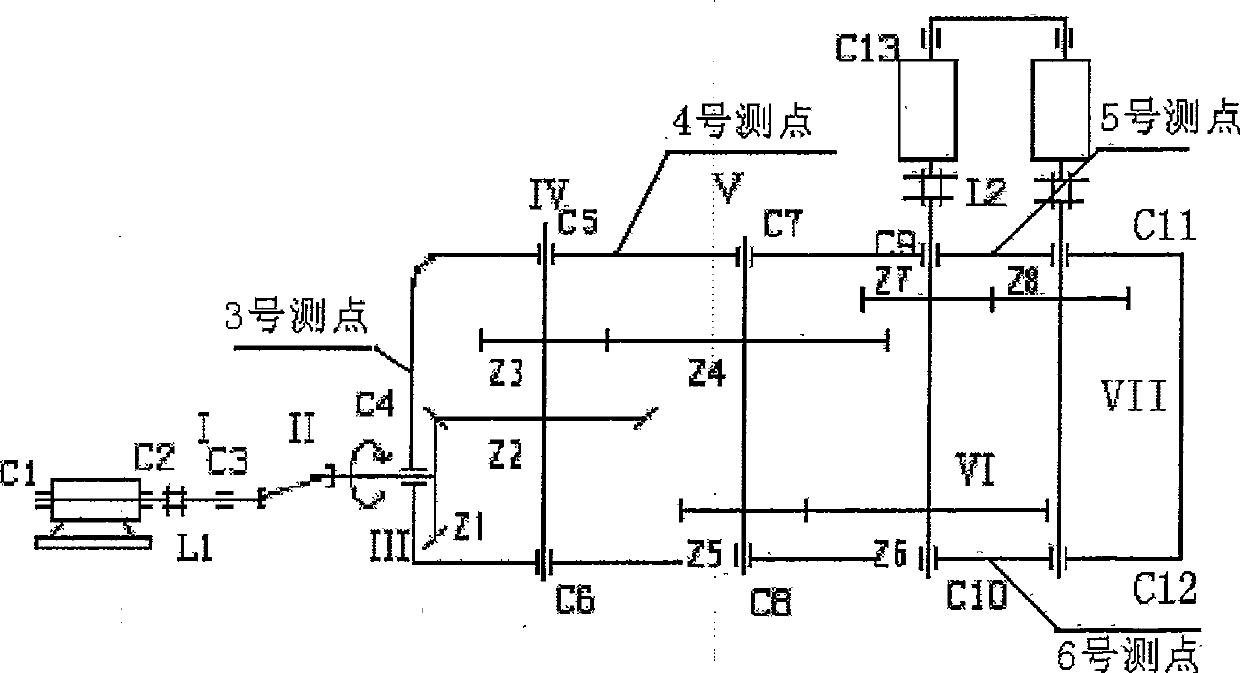

[0050] image 3 It is the gearbox transmission diagram of the blooming mill of a steel mill. A set of monitoring system is assembled on the gear box of the blooming mill, and six measuring points are respectively arranged in different parts of the gear box. Due to external influences such as heavy load and impurities, the rolling elements of the C10 bearing suffered from pitting, wear and loosening. Until 18:45 on May 6, 2003, the outer ring ruptured under the sudden impact of rolling force during steel rolling. When the bearing is broken, the bottom of the shaft VI loses its support and cannot rotate on its center of rotation, resulting in unbalanced operation, the transmission relationship of the gears on it is destroyed, and the force on the tooth surface is uneven. Finally, under the action of various complex forces, Teeth on multiple gears were broken off.

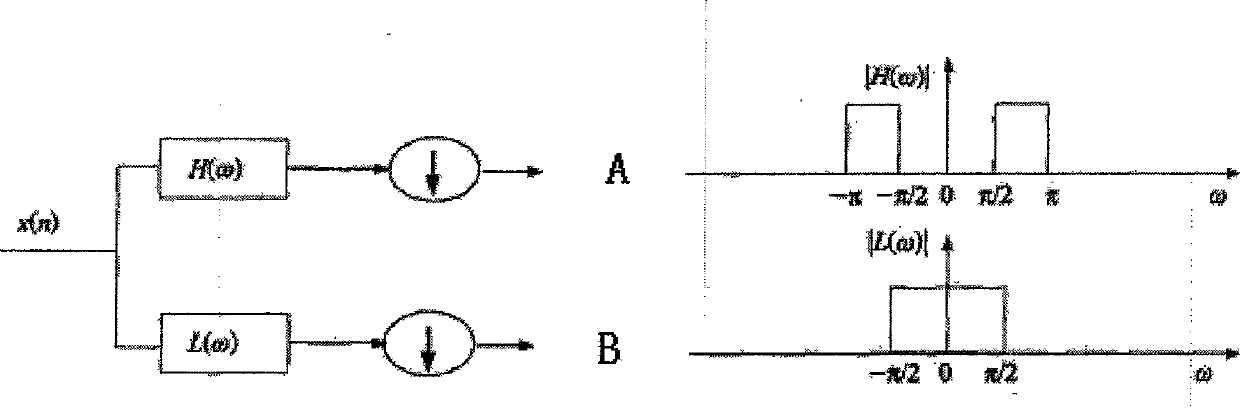

[0051] (1) Use a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com