Reciprocating driver

A driving device, reciprocating technology, applied in the directions of rider driving, transportation and packaging, vehicle parts, etc., can solve the problems of easy damage of central axis parts, weak fixing and self-locking, waste of angular travel, etc., to achieve a more structural and efficient Superior riding performance and improved transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

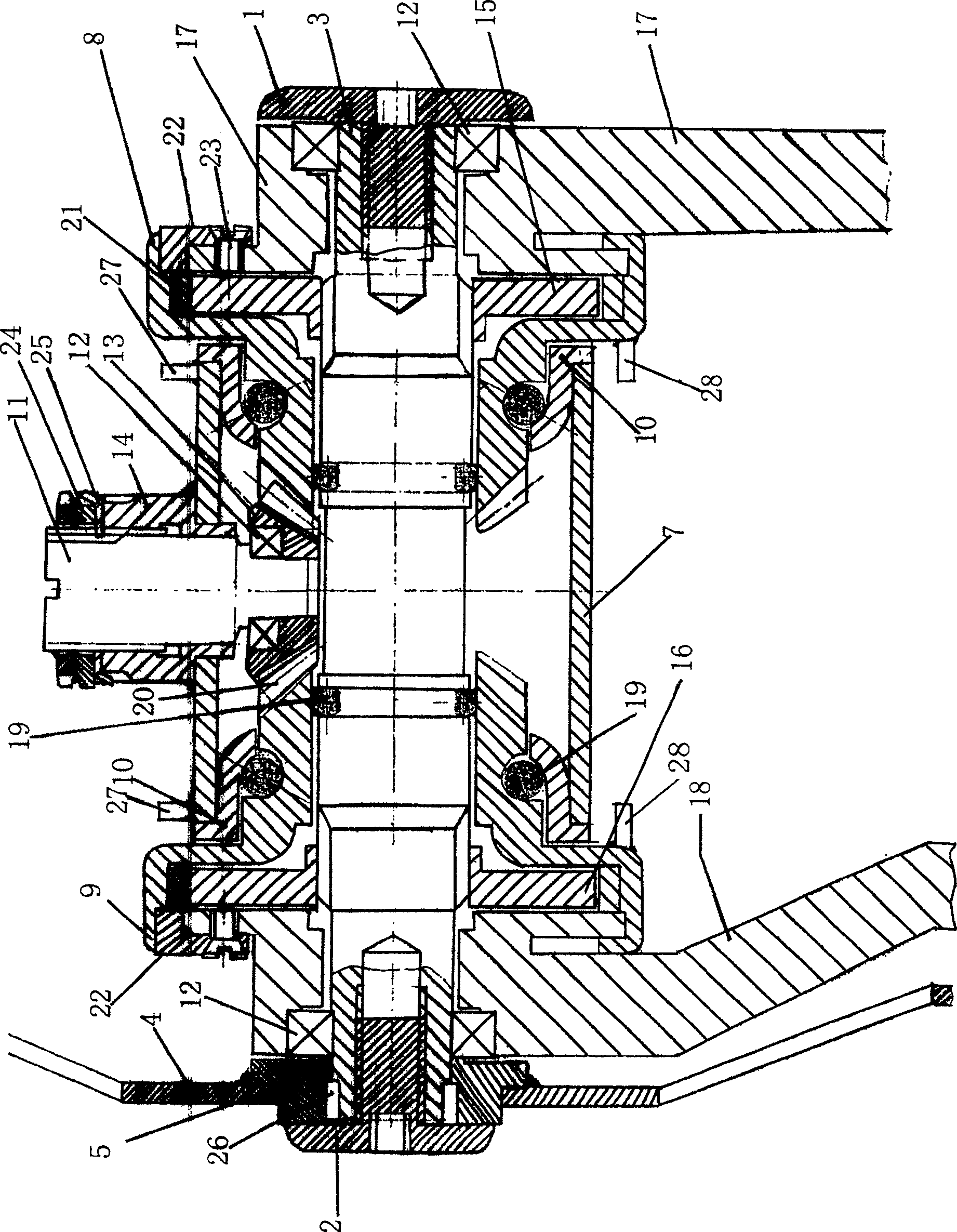

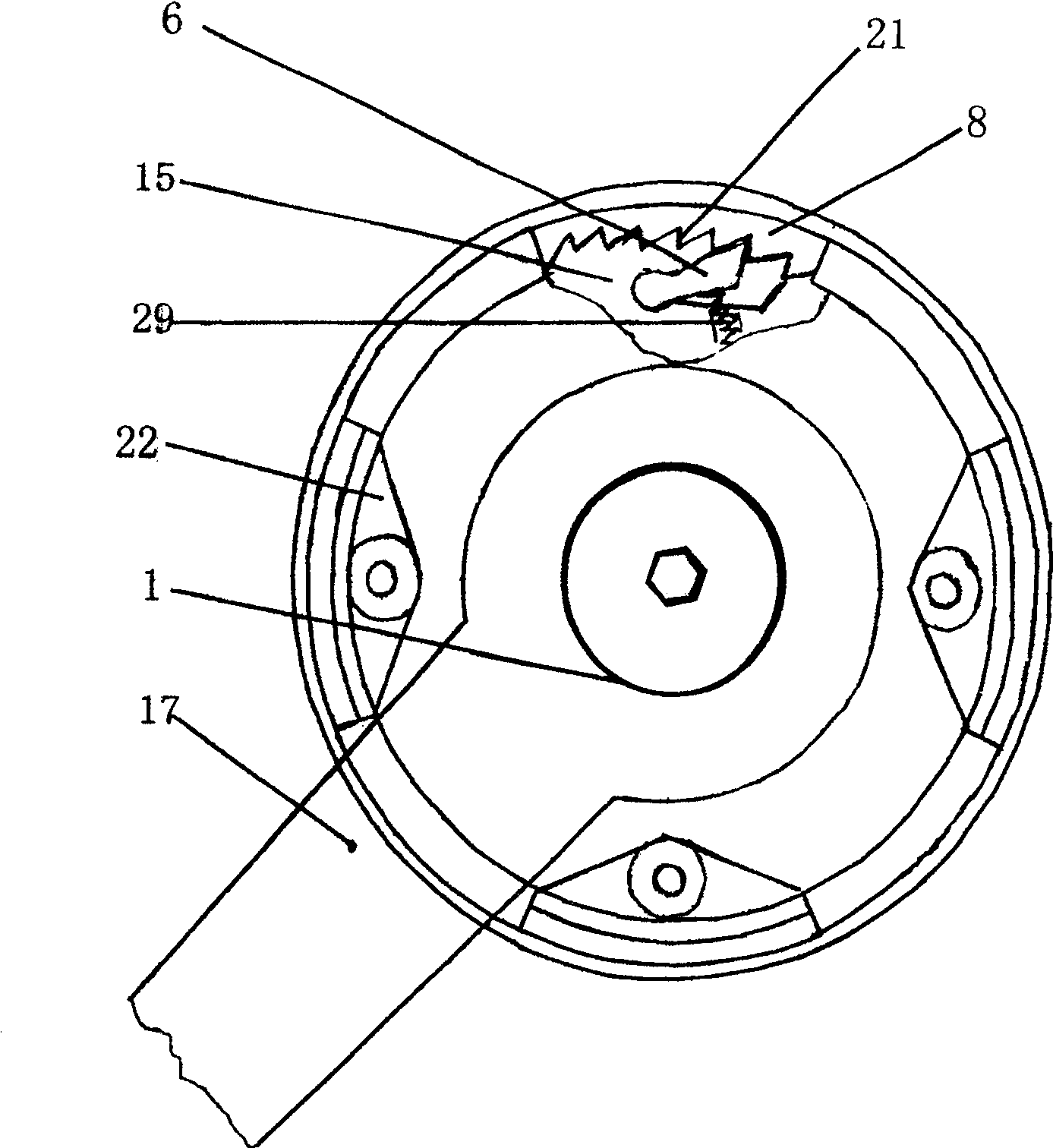

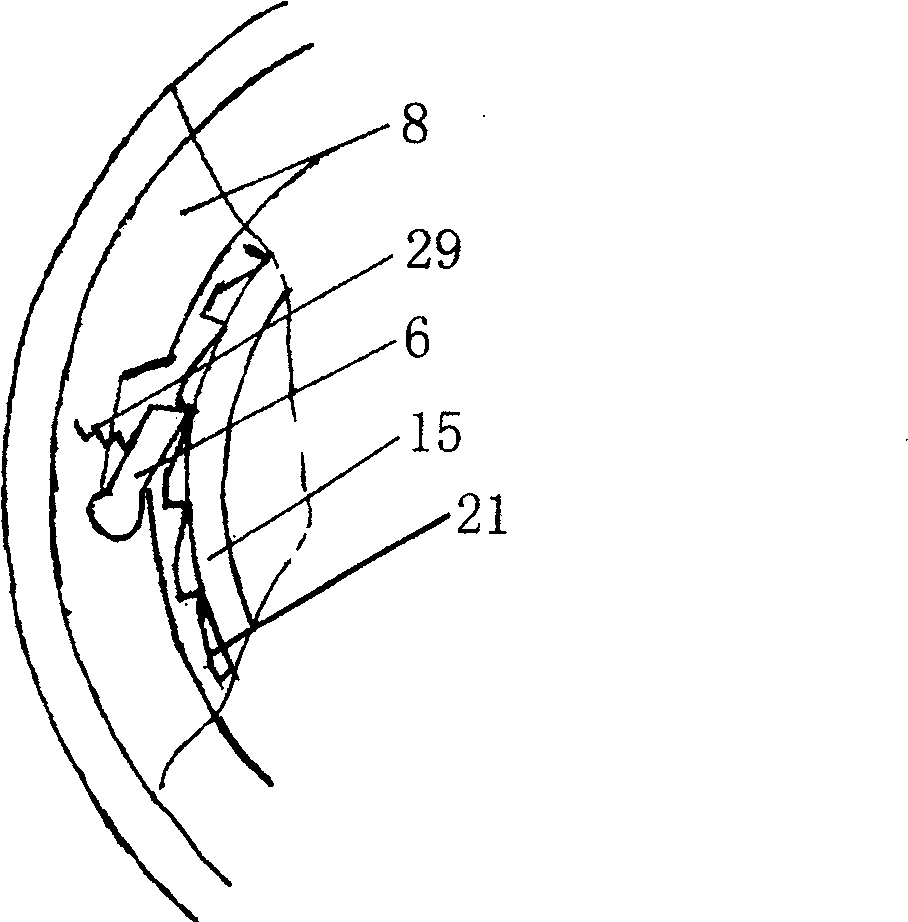

[0023] Such as figure 1 and figure 2 The reciprocating driving device shown includes left and right end covers 1 and 2, a central shaft 3, a sprocket 4, a sprocket seat 5, a pawl 6, and a central joint 7. The central shaft 3 is inside the central joint 7, and the central shaft 3 There are left and right pendulum rings 8 and 9 on the upper sleeve, and the center shaft bowl 10 is overlaid on the left and right pendulum rings 8 and 9, and a mediation shaft 11 is provided between the left and right pendulum rings 8 and 9, and the bottom of the mediation shaft 11 is provided with a bearing 12 and an intermediate joint. Wheel 13, middle connecting wheel 13 meshes with left and right pendulum rings 8 and 9 bevel teeth 20, mediation shaft 11 is located in mediation seat 14, left and right ratchets 15 and 16 on the central axis are housed in left and right pendulum rings 8 and 9, in The outsides of the left and right ratchets 15 and 16 are provided with left and right axle handles 17...

Embodiment 2

[0034] The balls in Embodiment 1 are replaced by rollers, needle rollers, bearings or oil bearings. There are three mediation shafts and three pawls. On the pendulum ring, the periphery of the left and right ratchet wheels is a ratchet, and the cross-sectional shape of the right crank is elliptical, semicircular or triangular, and the left and right pendulum rings and the left and right cranks are fixed by expansion rings.

[0035] There are 1-5 mediation shafts, which are eccentric shafts with an eccentricity of 0.1-1mm, and 1-10 ratchets.

[0036] Working principle of the present invention:

[0037] The left and right cranks installed on the central shaft are fixedly combined with the left and right swing rings respectively. Because the left and right cranks swing to drive the left and right swing rings to swing, the swing ring positioning blocks on the left and right swing rings alternately collide with the middle joint positioning blocks during driving to obtain the best ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com