Detection method and apparatus for barrel type steel ball grinder load based on multiple sensor fusion

A technology of multi-sensor fusion and load detection, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problem of difficult load detection of cylindrical steel ball mills, and achieve low cost, comprehensive load information, and easy maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

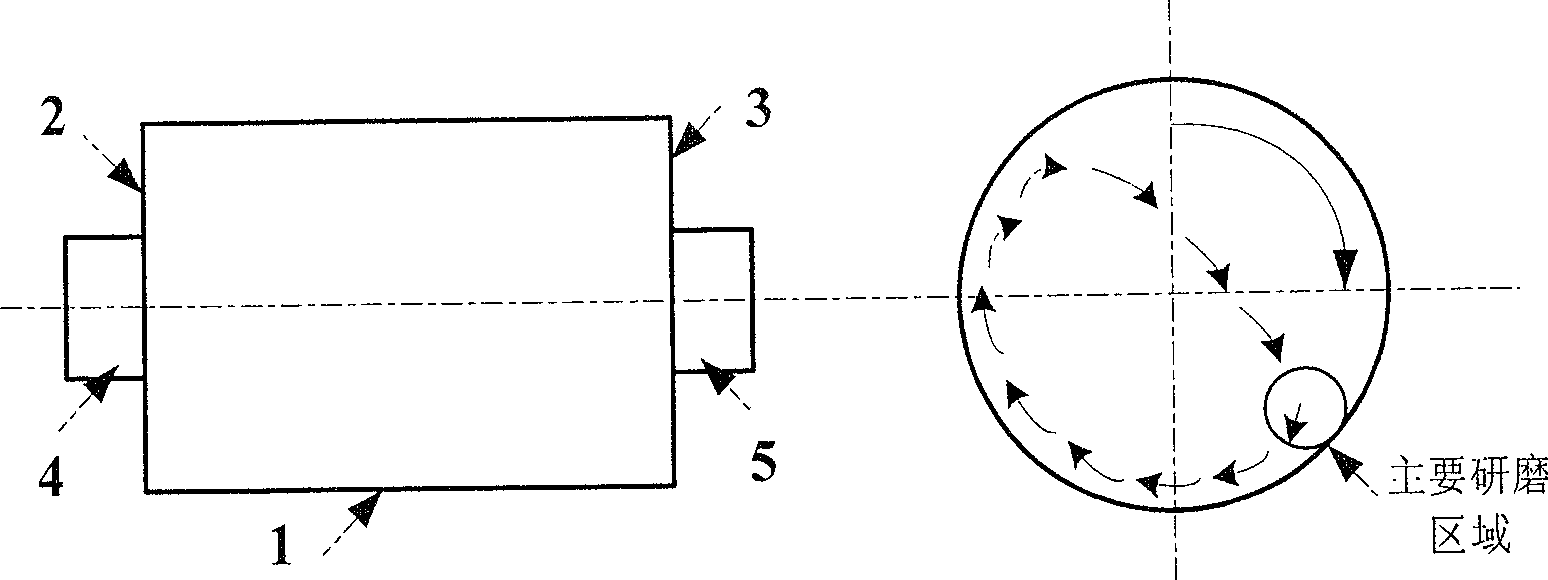

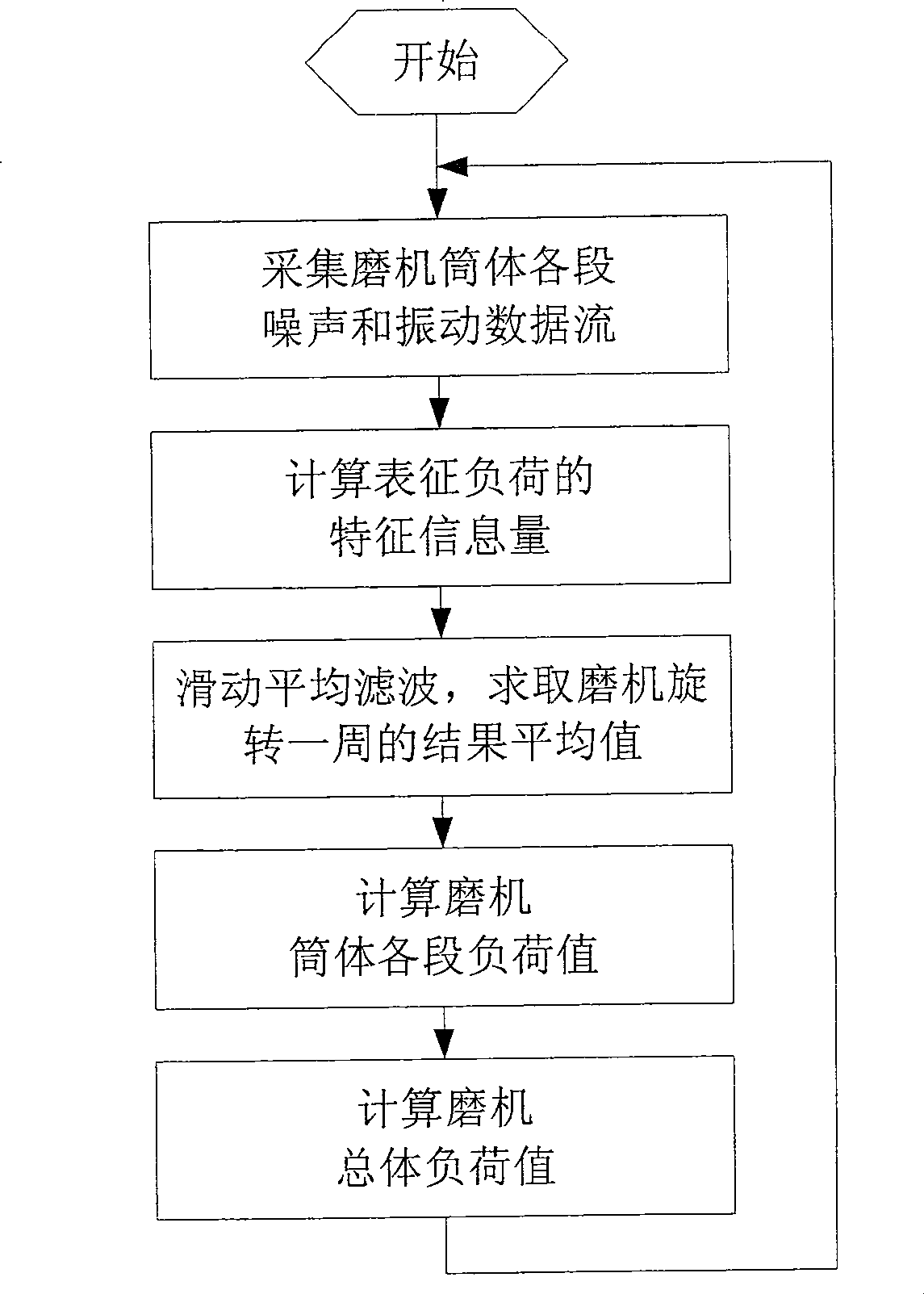

[0038] The present invention proposes a load detection method based on multi-sensor fusion for a drum ball mill, and its overall flow is as follows figure 2 As shown, it specifically includes the following steps:

[0039] 1) Install multiple sound sensors and vibration sensors in each section of the cylinder ball mill, and collect the noise and vibration information of each section of the cylinder ball mill at the same time, and obtain the noise and vibration data stream;

[0040] Among them, the sound sensor chooses a capacitive unidirectional microphone, and the response frequency is 20Hz-10kHz. For a single-chamber steel ball mill, install three sound sensors, which are respectively located at 1 / 4, 1 / 2, and 3 / 4 of the entrance of the cylinder; for a multi-chamber steel ball mill, the number of sound sensors installed is equal to the barrel The number of chambers of the steel ball mill is installed in the middle of each chamber of the steel ball mill; the sound sensor poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com