A making method of cathode material for lithium ion battery

A technology for lithium ion batteries and cathode materials, which is applied in the field of preparation of cathode materials for lithium ion batteries, can solve the problems that powder particles are difficult to achieve spherical effect, pollute the natural environment, and are difficult to recycle, and achieve convenient doping and simple operation. , the effect of easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

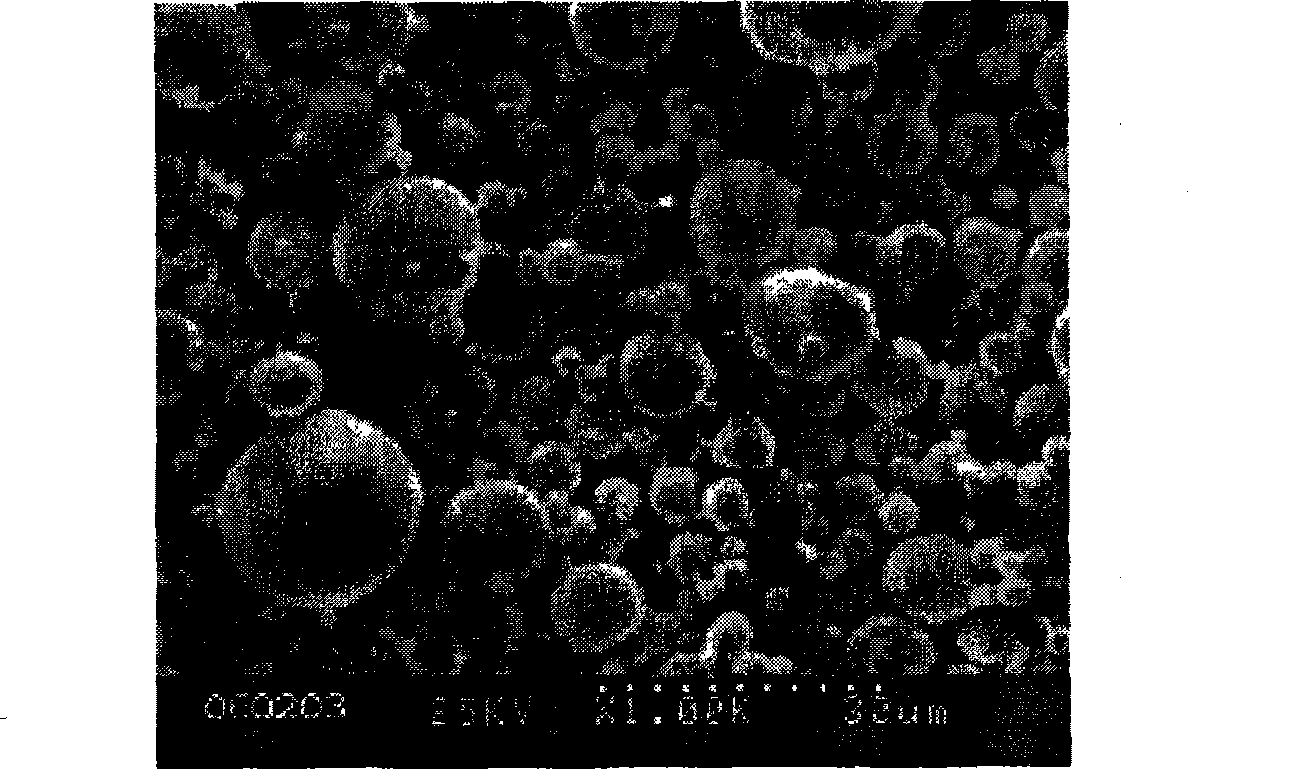

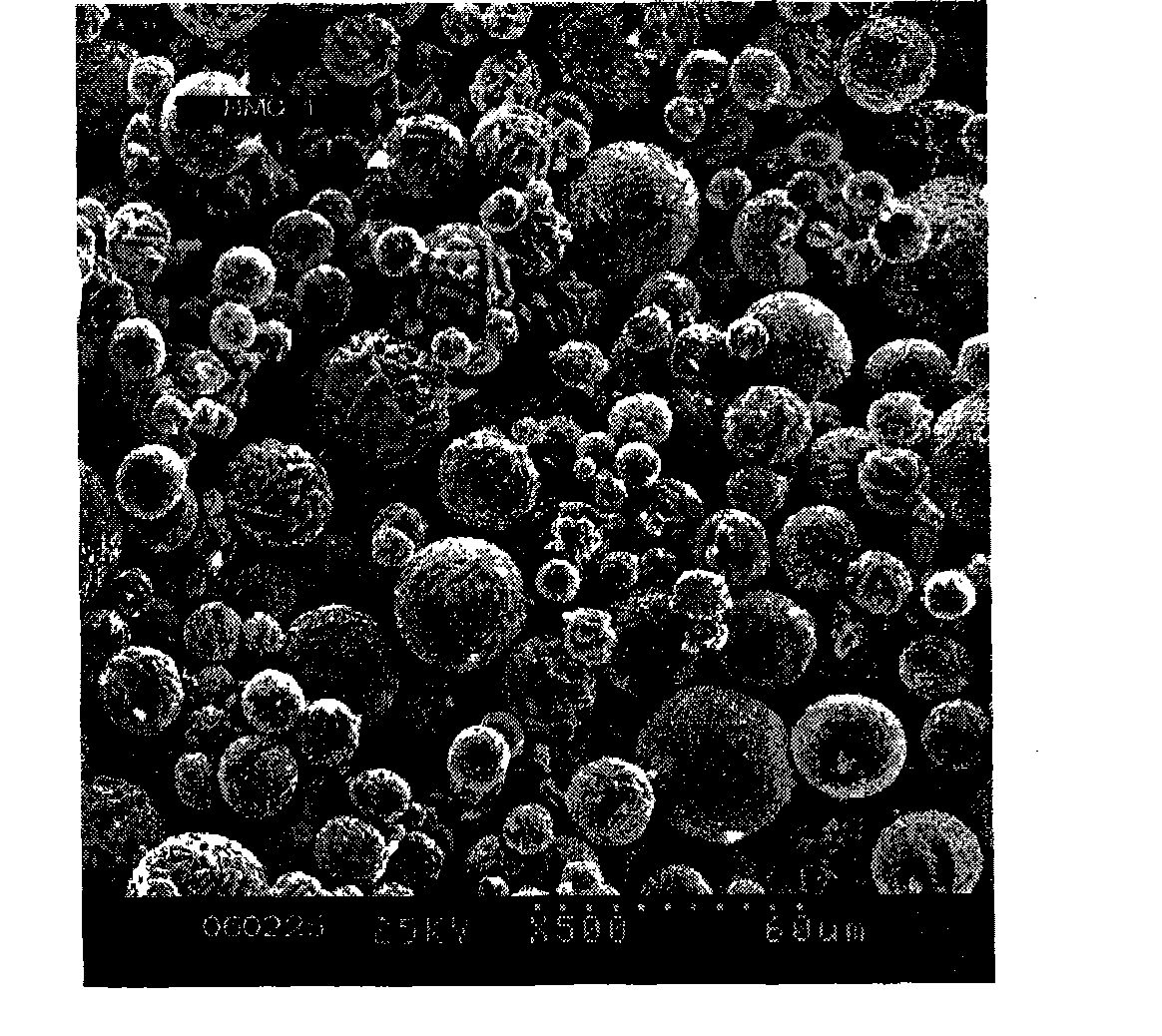

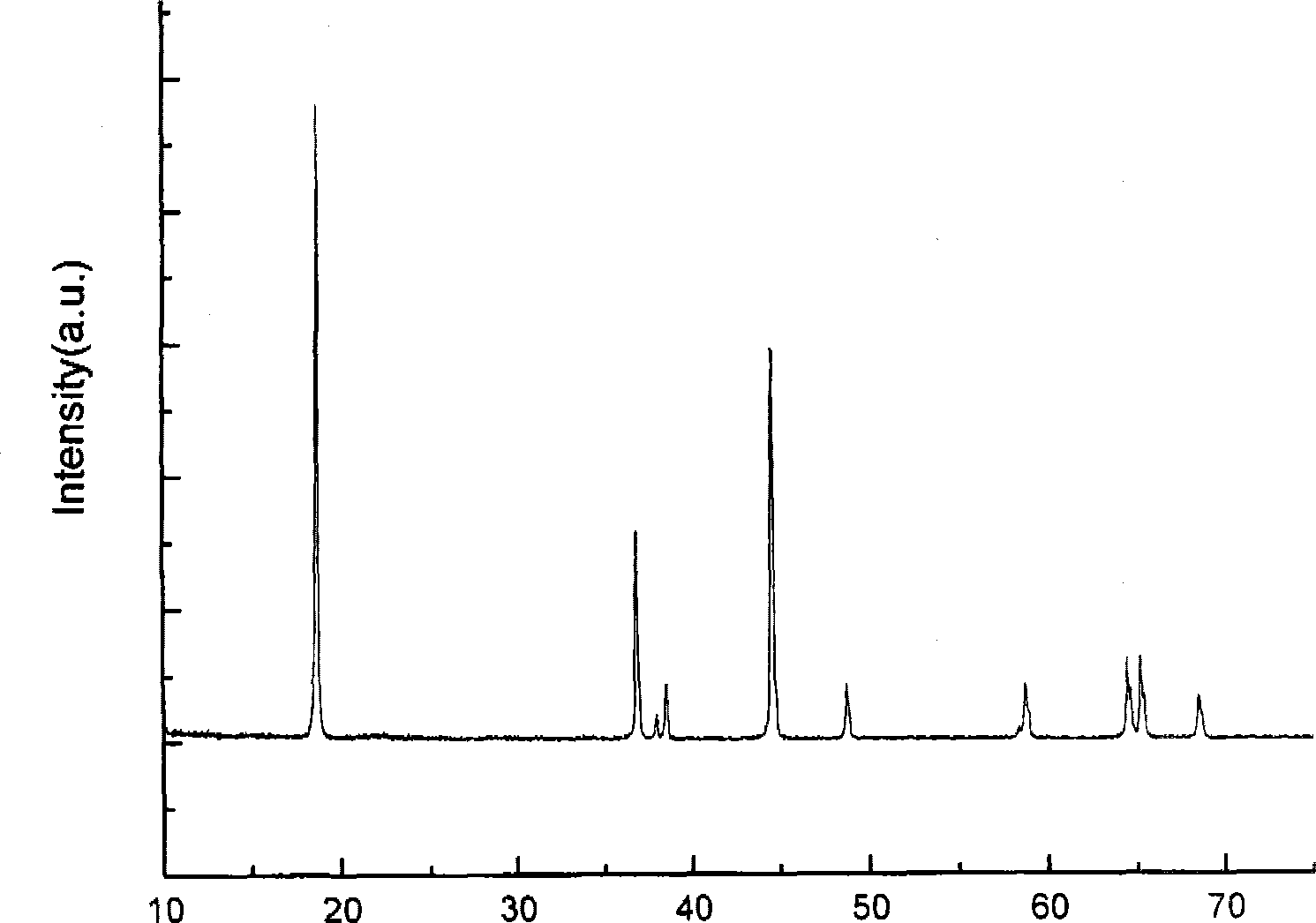

[0020] Prepare 100 kg of mixed metal according to the mass ratio of Ni, Mn, and Co at 1:1:1, add it to an intermediate frequency furnace and heat it to melt it, and when the temperature reaches 1600-1680°C, inject the molten metal into the atomizing device and start the high-pressure water pump , the water pressure is controlled at 27±1Mpa, and the high-pressure spray acts on the metal liquid flow to prepare Ni with a median particle size D50 of 10.2μm 1 / 3 co 1 / 3 mn 1 / 3 alloy powder, figure 1 SEM photograph of the powder. The powder was calcined in a muffle furnace at 500°C to obtain a composite metal oxide Ni 1 / 3 co 1 / 3 mn 1 / 3 o 2 . Will Li 2 CO 3 with the Ni obtained above 1 / 3 co 1 / 3 mn 1 / 3 o 2 According to the molar ratio Li / NiMnCo=1.03, it is fully mixed and then calcined at 900°C for 20 hours to obtain LiNi, a cathode material for lithium-ion batteries with a high vibration ratio. 1 / 3 co 1 / 3 mn 1 / 3 o 2 , figure 2 It is the SEM photo of the material, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com