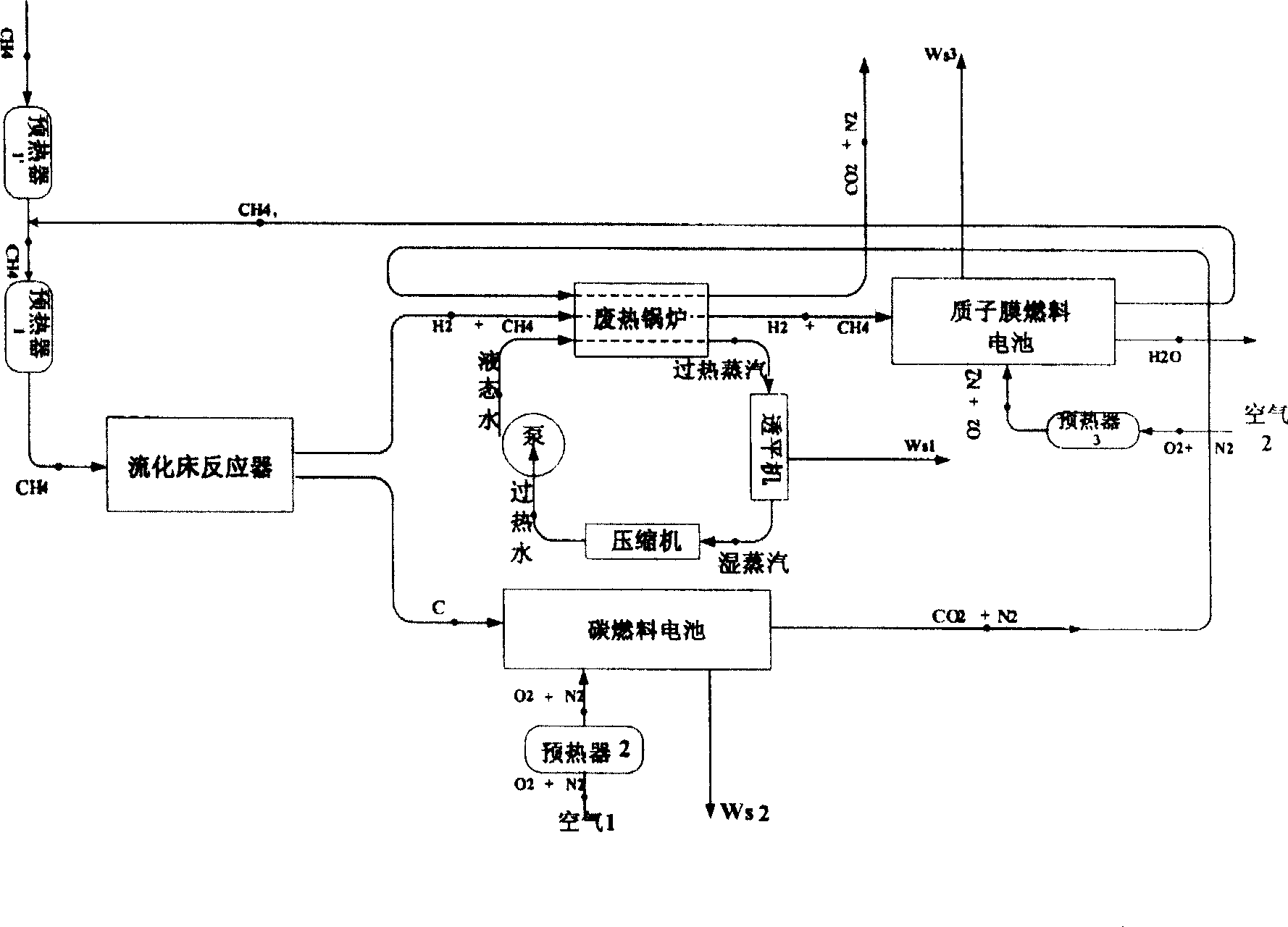

Power system based on methane cracking and fuel battery

A fuel cell and energy system technology, applied in the field of energy systems, can solve problems such as complex reaction processes, and achieve the effects of simple and easy processes, broad market prospects, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The methane preheating is carried out in two stages. The first stage heats the fresh methane from normal temperature (25°C) and normal pressure (latm) to 100°C through the preheater 1′, and the second stage heats the fresh methane from the preheater 1′ to 100°C. Methane is heated from 100°C to 600°C through preheater 1. Enter the fluidized catalytic cracking reactor, catalytic cracking at 600 ° C into nano-carbon fibers and hydrogen. The high-purity hydrogen recovers heat through the waste heat boiler, cools down to 100°C, and passes into the proton membrane fuel cell. At the same time, the oxidant air is heated to 100°C through the preheater 3, and then passes into the proton membrane fuel cell. It reacts with hydrogen to generate water at 100°C, which can be used as a living Sold with water. High-temperature nano-carbon fibers (600°C) are directly passed into the carbon fuel cell, while oxygen and nitrogen are heated from normal temperature to 650°C through the prehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com