Steel structure assisted layered installation and construction method for superhigh PRC partition plate

A construction method and steel structure technology, applied to walls, building components, building structures, etc., can solve the problems of difficult construction of super high partition walls, and achieve the effect of simple construction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

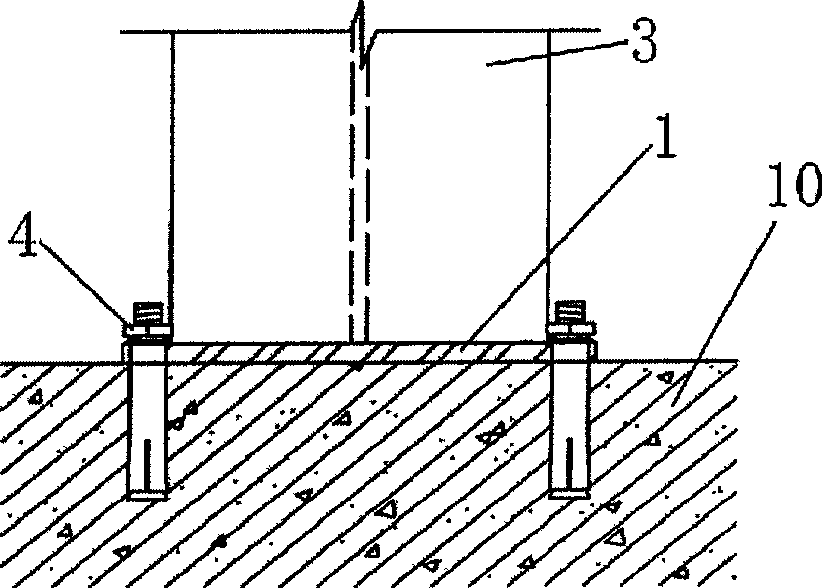

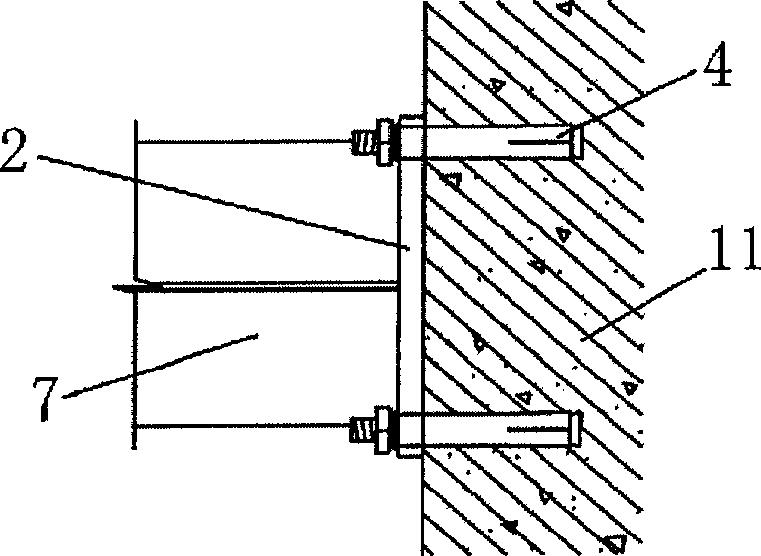

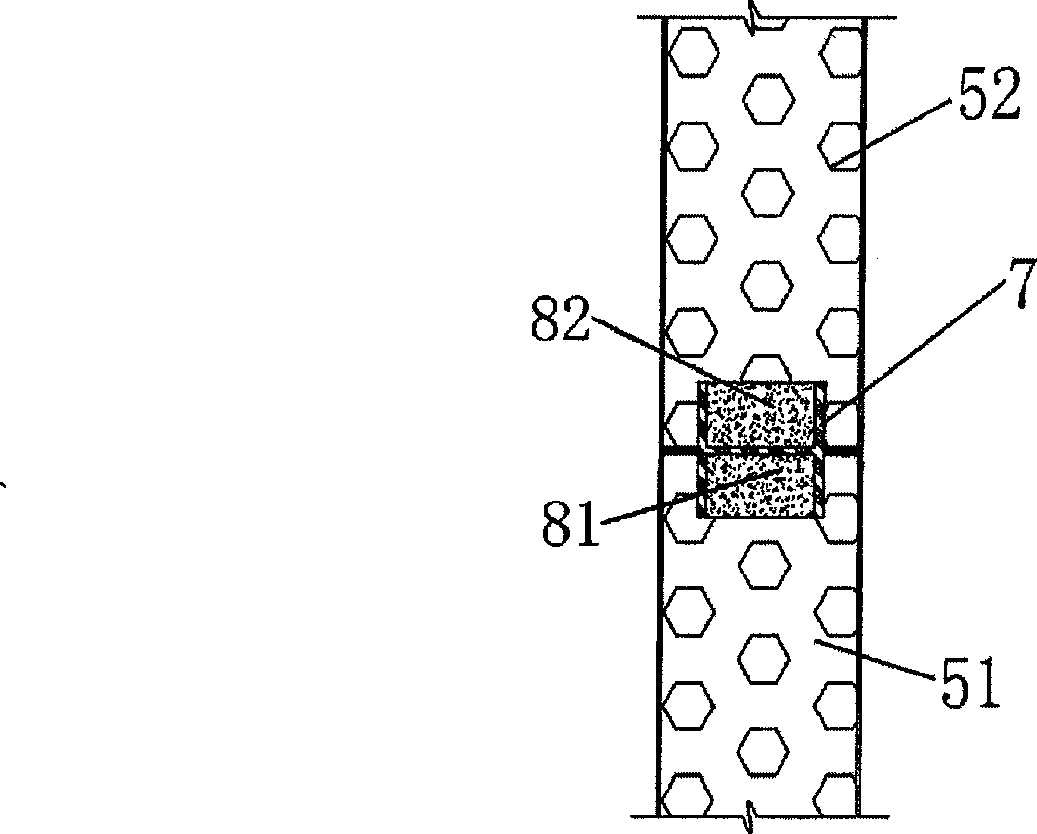

[0049] Examples see Figure 1-5 , when the PRC lightweight composite partition board is installed, for walls with a height of more than 5.5 meters, the installation is planned to be installed by the steel structure auxiliary layered installation method, that is, a steel structure is installed every 4 meters along the length of the wall Column 3, a steel structure beam 7 is installed every 5 meters or so along the height direction of the wall body. The positions of the steel structure columns 3 and the steel structure beams 7 can be adjusted appropriately according to the actual size of the wall and the specifications of the PRC lightweight composite partition wall panels.

[0050] The specific construction process of super-high and super-long PRC partition wall steel structure auxiliary layered installation is as follows:

[0051] Step 1: Determine the position of the steel structure column feet and beam connectors according to the drawings and on-site setting-out conditions;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com