Centrifugal fan and structure of stator thereof

A centrifugal fan and stator structure technology, which is applied to non-variable volume pumps, non-displacement pumps, components of pumping devices for elastic fluids, etc. 1 Problems such as inability to operate and being easily pulled away from the motor to achieve the effect of improving the ability to resist pulling by external forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

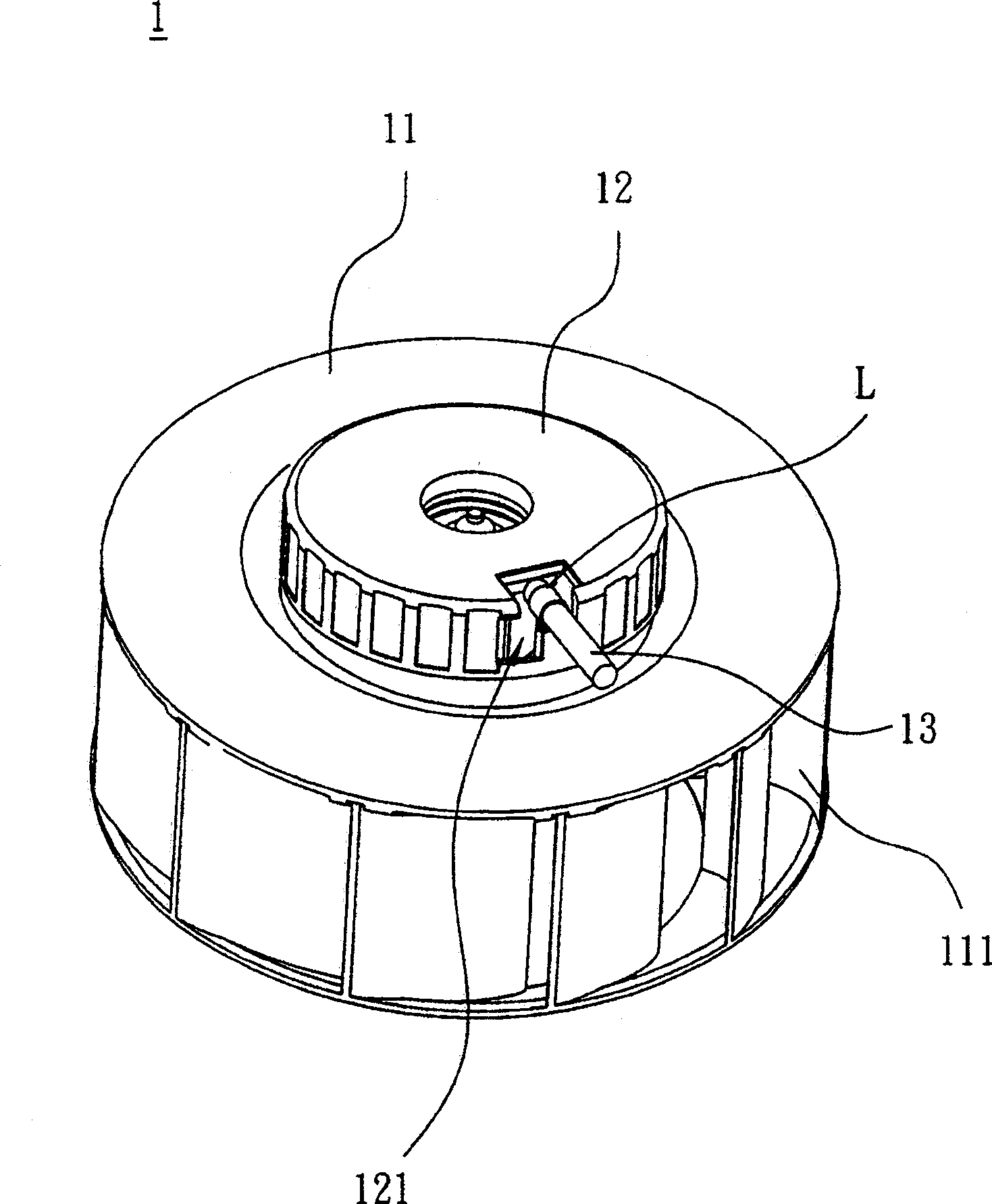

[0019] A centrifugal fan and its stator structure and base structure according to preferred embodiments of the present invention will be described below with reference to the accompanying drawings, wherein the same elements will be described with the same reference numerals.

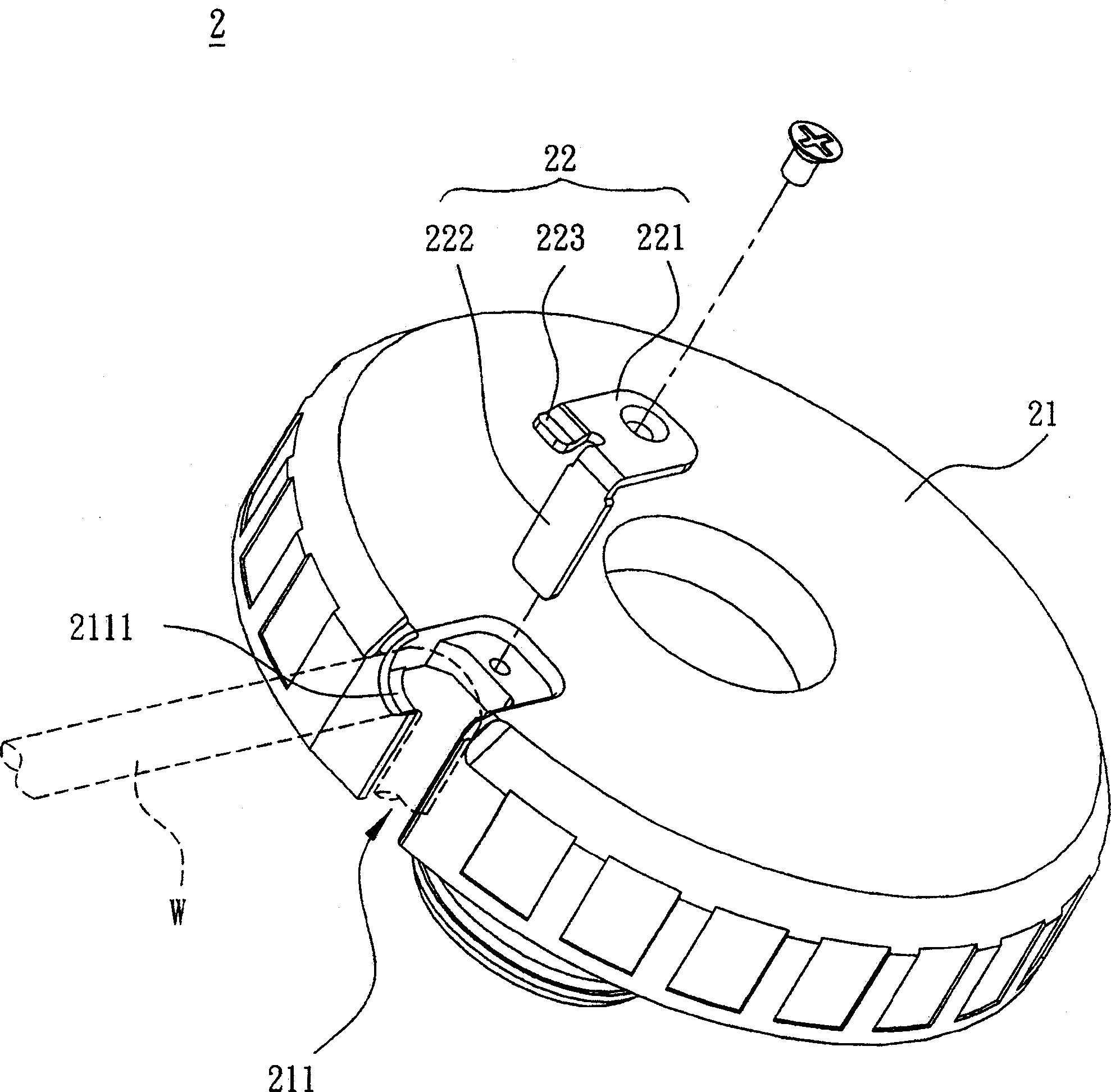

[0020] refer to figure 2 , a centrifugal fan seat structure 2 according to a preferred embodiment of the present invention can fix a wire W, and the seat structure 2 includes a body 21 and a fixing member 22 . A groove 211 is formed on the periphery of the body 21 , and the wire W can easily pass through the groove 211 to be placed in a positioning portion 2111 of the groove 211 .

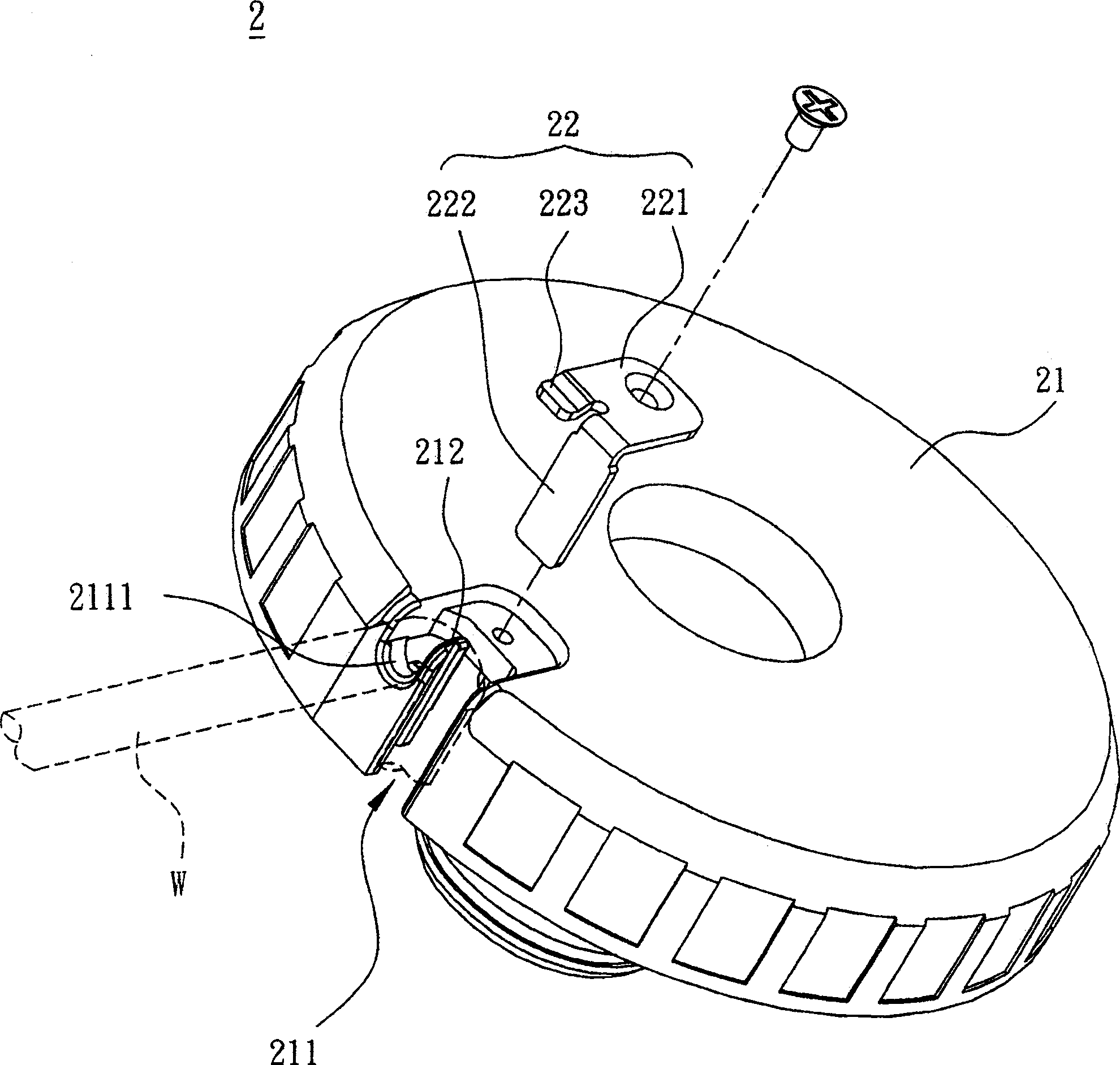

[0021] refer to image 3 In order to align and fix the wire W on the positioning part 2111 more accurately, the body 21 also has a stopper part 212, which protrudes from the groove 211 and adjoins the positioning part 2111, and is used to limit the positioning of the wire W. Section 2111. The material of the body 21 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com