Method for producing substrates

A substrate and deviation technology, applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit components, etc., can solve problems such as circuit board defects, different deformation characteristics, and insufficient overlapping of connection surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

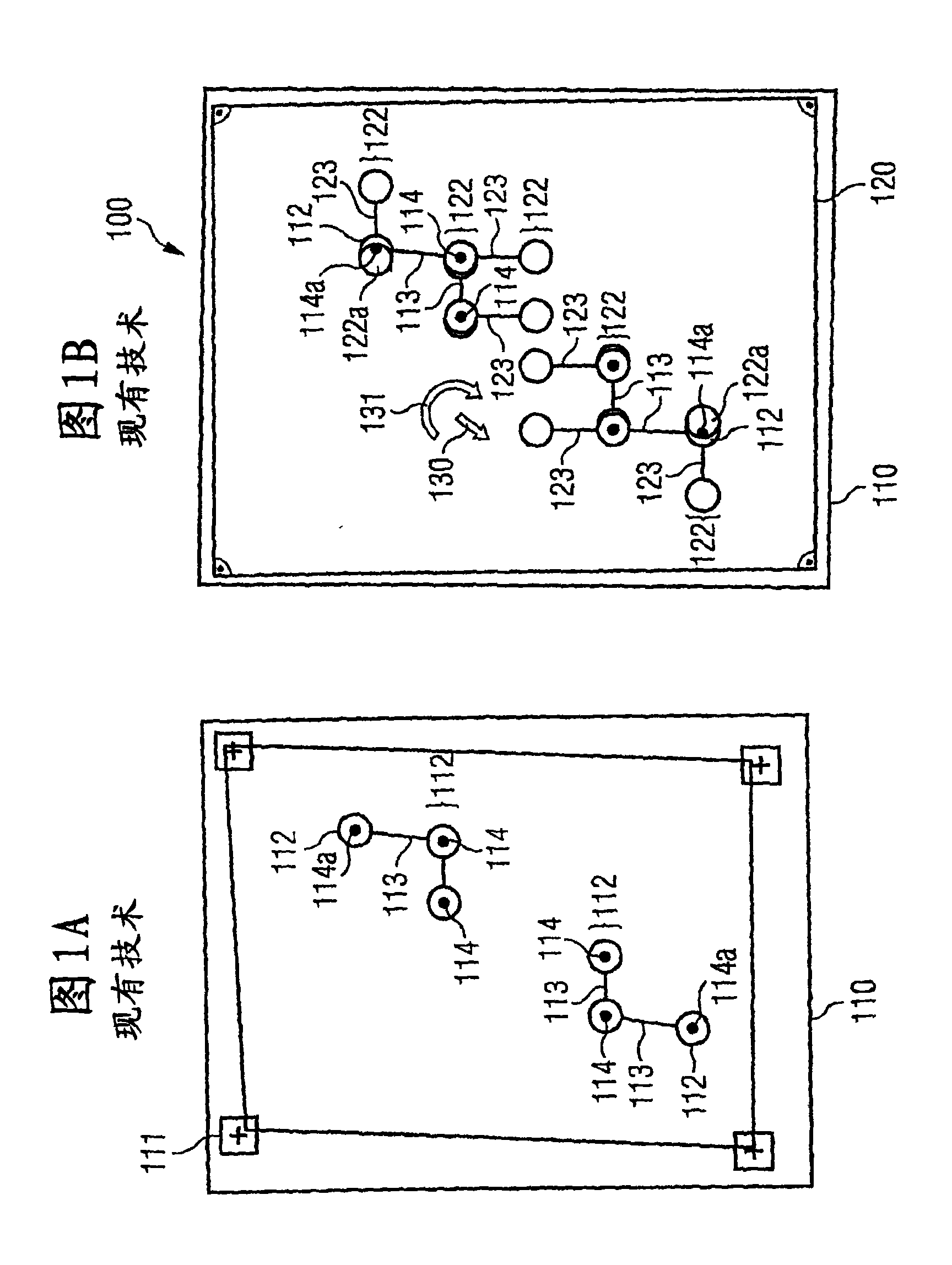

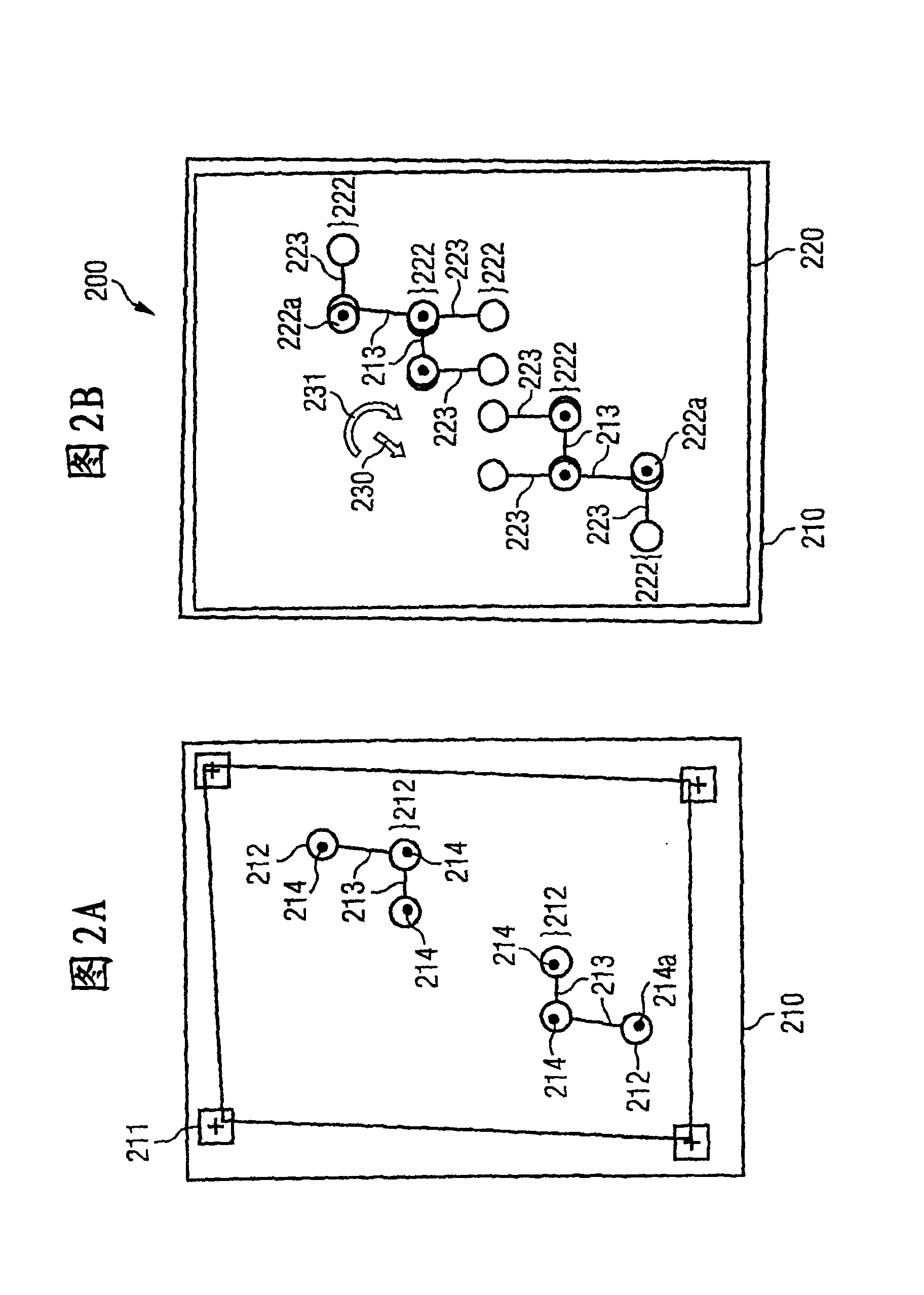

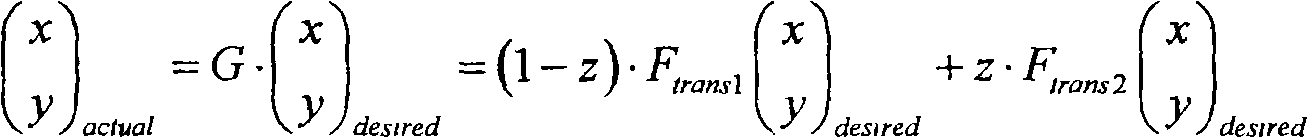

[0027] Figures 1a and 1b illustrate the manufacture of a circuit board 100 structured in layers according to the prior art. The construction of the circuit board 100 begins with a first layer 110 with four markings 111 applied thereto. The positions of these markers are measured and a transformation according to Equation 1 is determined from the deviation between the actual position and the respective ideal position, by means of which transformation the deformation of all grid points of the first layer 110 is determined. Usually, this deformation can be easily obtained for all grid points.

[0028] According to the presently shown embodiment, the printed wire structure formed on the first layer 110 includes a total of six first connection surfaces 112, and these six connection surfaces are divided into two groups, and each group includes three first connection surfaces 112 . The connection areas 112 in each of the two groups are connected via two first conductor tracks 113 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com