Chainless type maize harvesting and stalk returning device

A corn and straw technology, applied in the field of chainless corn harvesting and straw returning devices, can solve the problems of poor adaptability of row spacing, difficulty in front-loading, serious soil breaking, etc., and achieves increased working width, high safety and reliability, and adaptable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

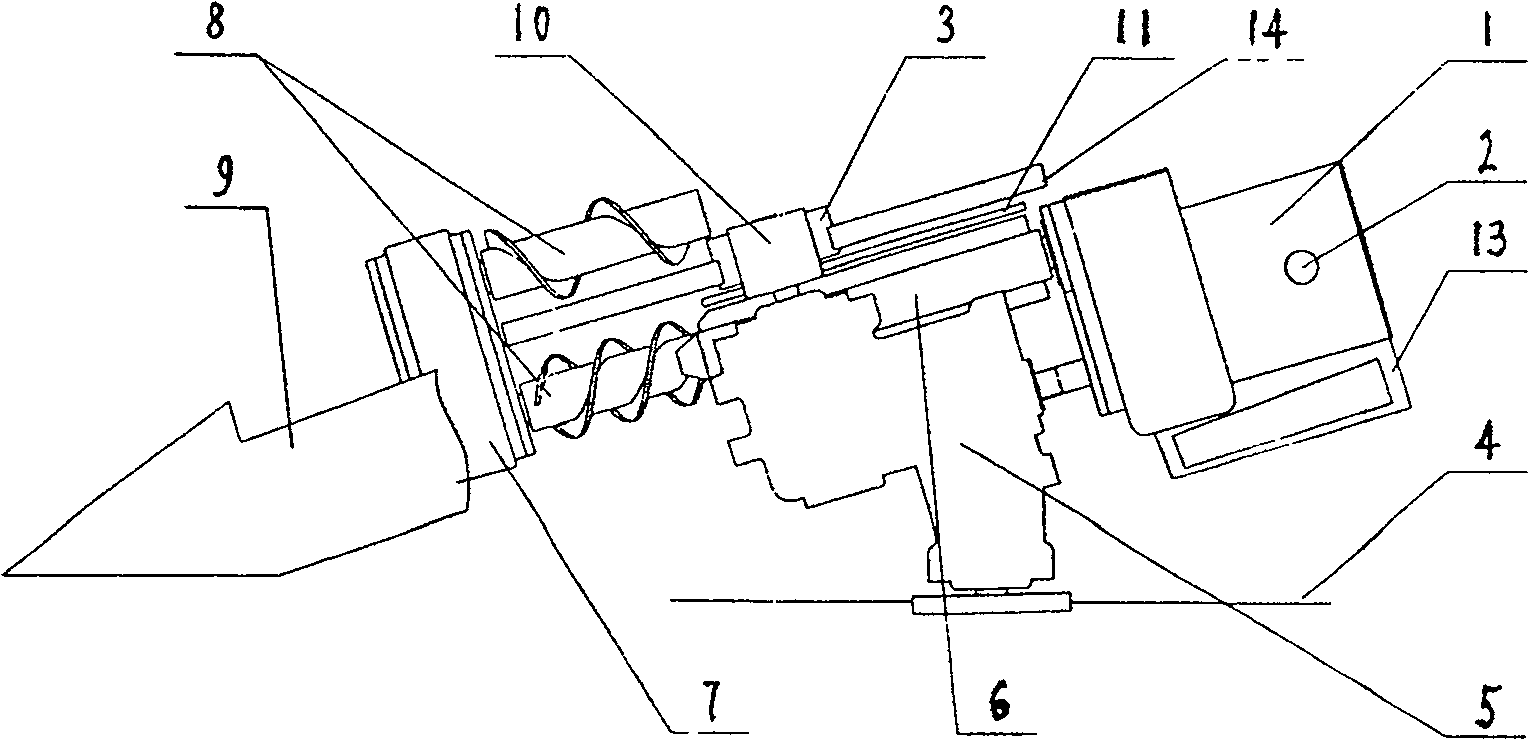

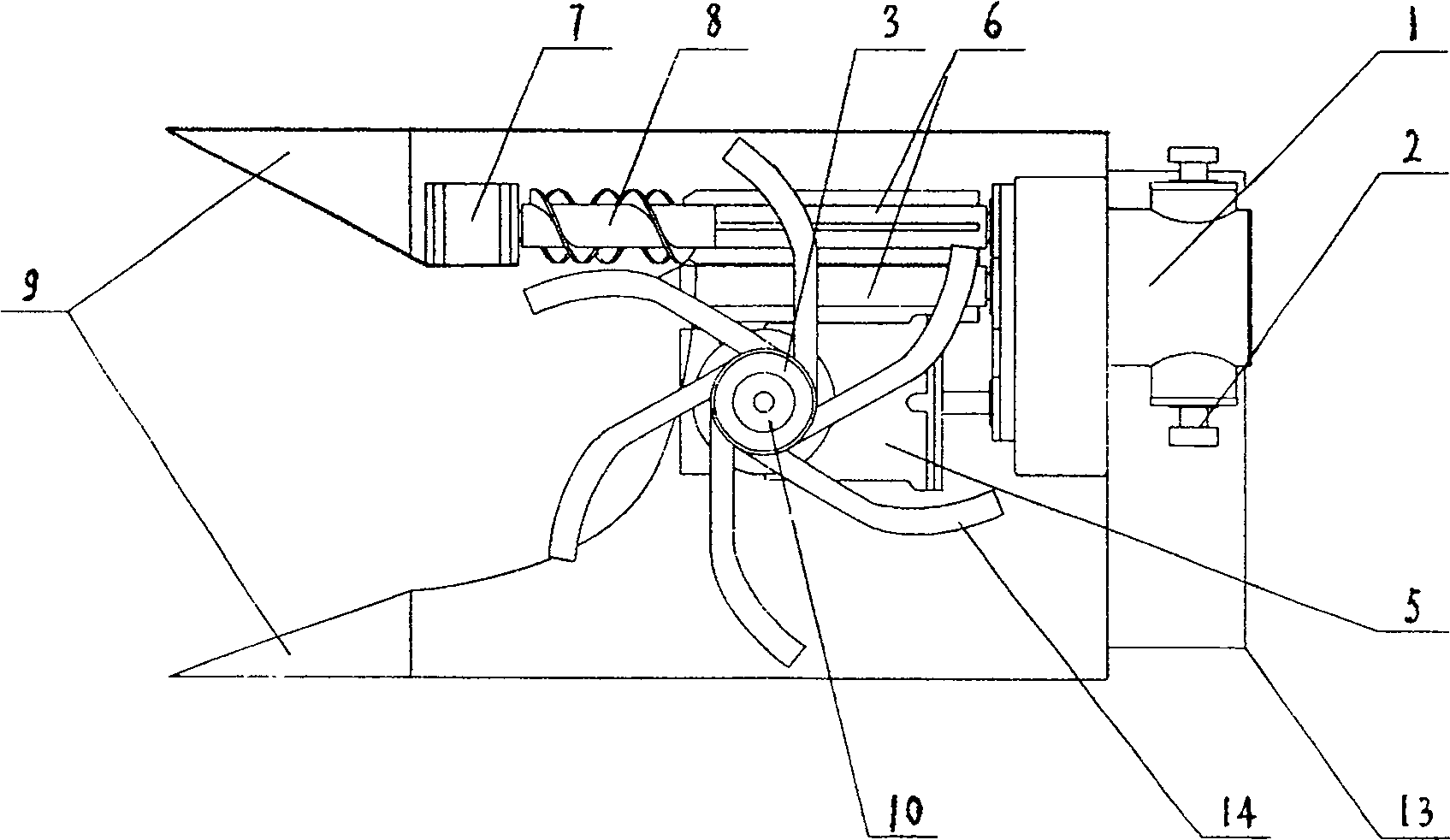

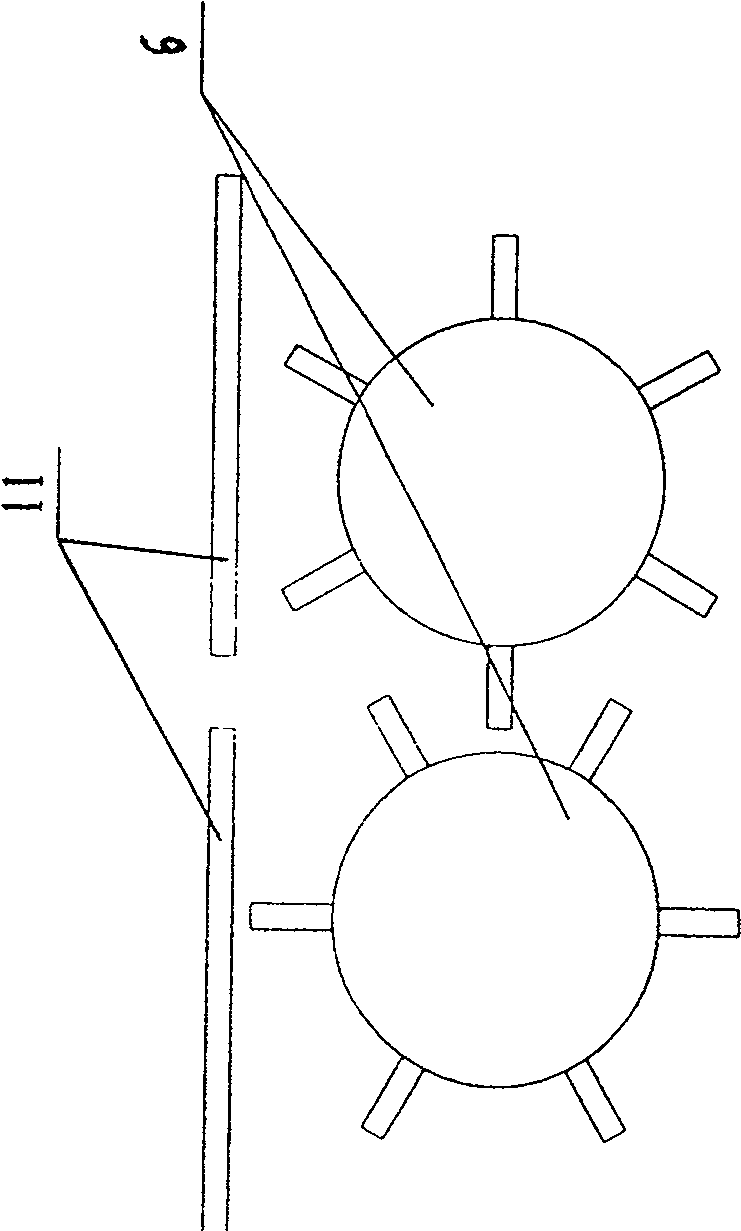

[0022] 1. Main gearbox 2, power input shaft 3, reel 4, cutter 5, chopping-reel gearbox 6, stem puller 7, gearbox 8, screw feed roller 9, grain divider 10, Safety clutch 11, ear picking plate 12, horizontal ear picking roller 13, frame 14, grain picking finger

[0023] exist Figure 1~3 In the shown embodiment: the main gearbox 1 is installed on the frame 13, and its input end is connected with the power source via the power input shaft 2, and its two output ends are correspondingly fixedly connected with the two pulling stem rollers 6, and its third output end It is fixedly connected with the input end of chopping-reeling gearbox 5, and the reel 3 suit is fixed on the output end of chopping-reeling gearbox 5 at the top, and its periphery is provided with 6 reeling fingers 14. Knife 4 is fixed on the output end of chopping-reeling gearbox 5 and is located at the bottom. Every cutting knife 4 is a flat knife with a blade on one side. Two stem pulling rollers 6 are parallel to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com