Reel front cleaning mopping machine

A technology of mopping machine and cleaning mechanism, which is applied in the direction of cleaning carpets, cleaning machinery, cleaning floors, etc., can solve the problems of complicated movement of clamping arms and jaws, disturbing the driver's sight, uneven cleaning, etc., to improve the quality of mopping and cleaning. , Improve work efficiency and facilitate cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

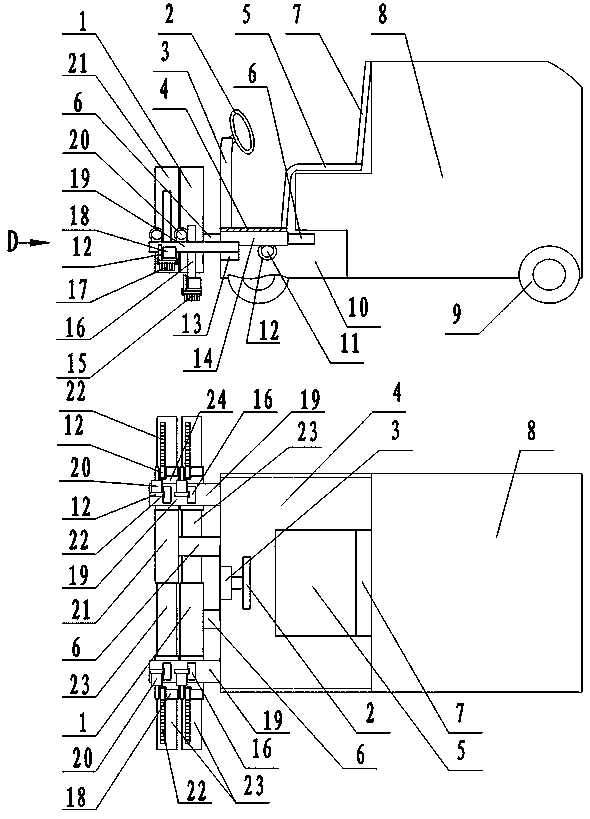

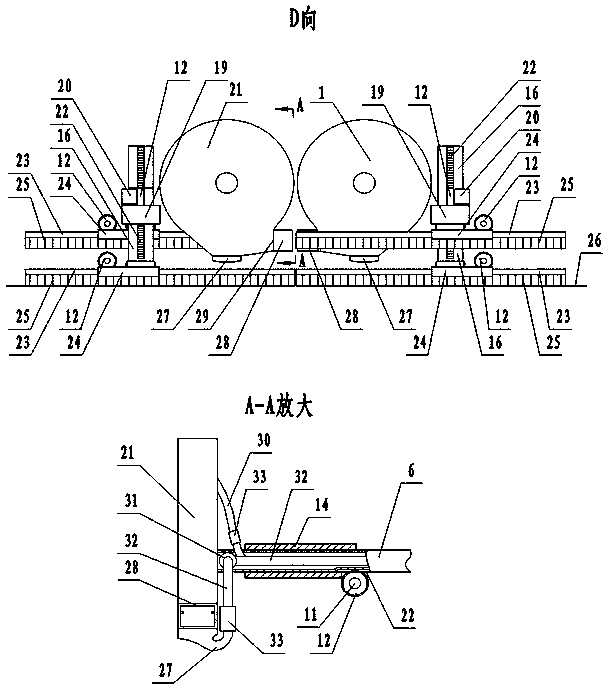

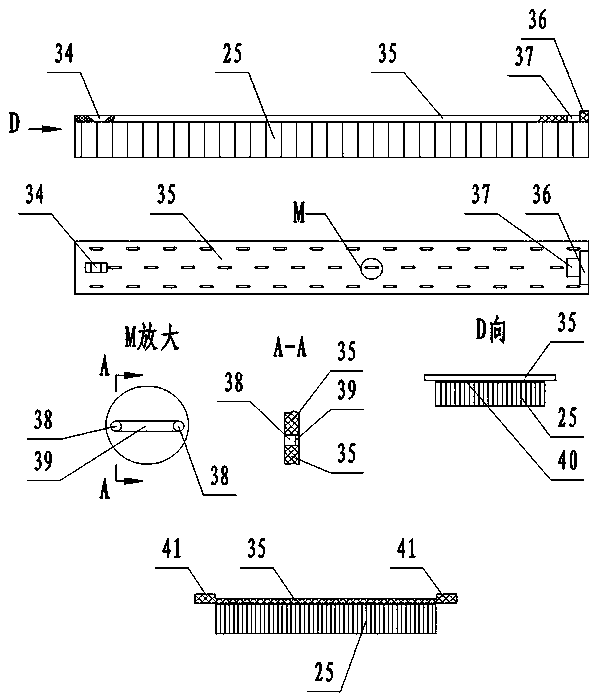

[0020] figure 1 In the middle is the overall structure diagram of the reel pre-cleaning and mopping machine. The upper picture is the front view, and the lower picture is the top view. figure 2 in, yes figure 1 D direction diagram. Two sets of mopping handkerchiefs are installed side by side on the front left and right of the car body of the reel front cleaning and mopping machine, each set of two handkerchiefs, and the left handkerchiefs on the left side of the car body, namely the two handkerchiefs below the picture below, are called the left handkerchief group , the two handkerchiefs on the right side of the car body are called the right handkerchief group. A broom handle 16 is all connected above every mopping handkerchief.

[0021] A broom handle frame 19 is respectively installed on the pedal 4 bottom left and right of the car body, and the broom handle frame 19 right sides are fixed on the frame 13 below the pedal on the car body. The broom handles connected above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com