Obstacle avoidance type snow sweeping device

A technology for obstacle avoidance and driving devices, which is applied in snow surface cleaning, cleaning methods, construction, etc., can solve problems such as waste of resources, snowmelt pollution, corrosion of road surfaces, etc., and achieve a high degree of automation, a wide range of applications, and increase the operating width. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

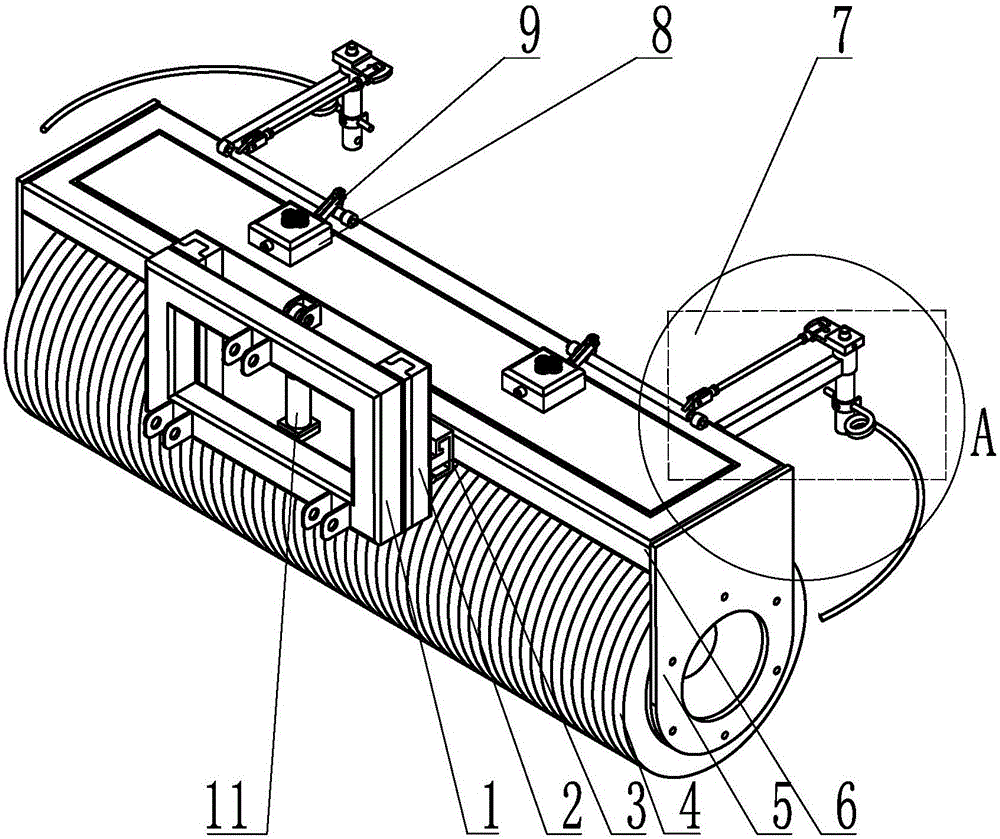

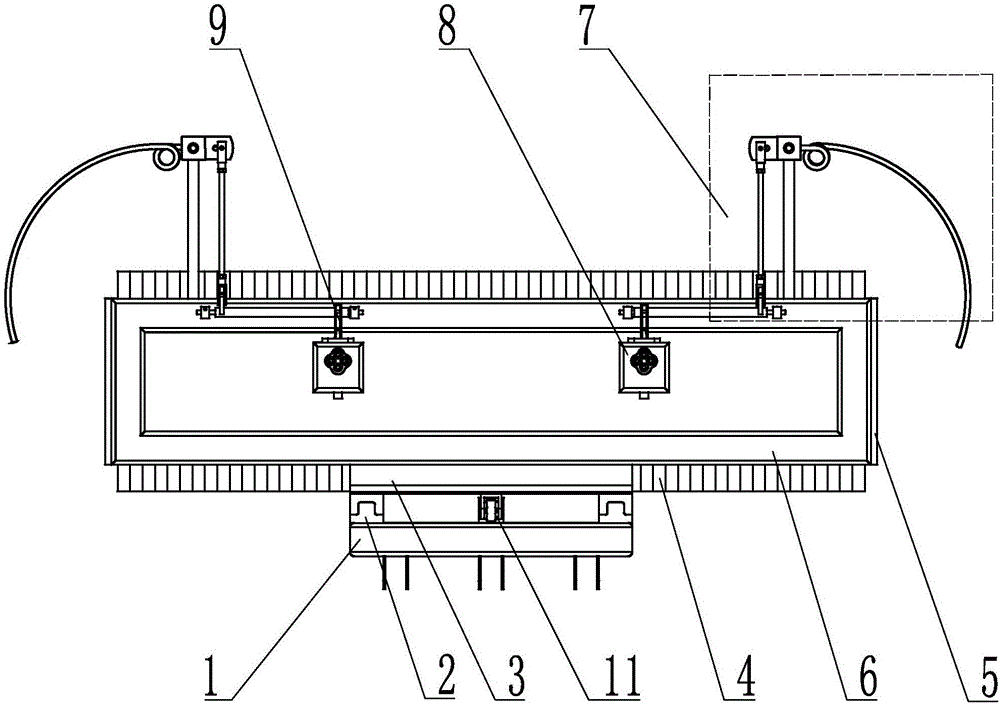

[0029] Embodiment 1: refer to Figure 1~5 , is a structural schematic diagram of Embodiment 1 of the present invention, an obstacle-avoiding snow removal device, including a fixed frame 1, a mobile frame 6, an obstacle sensing and signal transmission mechanism 7, a hydraulic valve 8, and a driving device for a snow removal roller assembly 10 and the snow-plowing roller assembly 4, which is characterized in that: the fixed frame 1 and the mobile frame 6 are provided with a mobile connection mechanism, the lower part of the mobile frame 6 is provided with a snow-plowing roller assembly 4, and the front part of the mobile frame An obstacle induction and signal transmission mechanism 7 is provided on the side; the mobile connection mechanism includes a chute mechanism and a hydraulic drive mechanism, and the chute mechanism includes a fixed frame chute 2 on a fixed frame 1 and a fixed frame on the mobile machine. The mobile frame chute 3 on the frame 6; the hydraulic drive mechani...

Embodiment 2

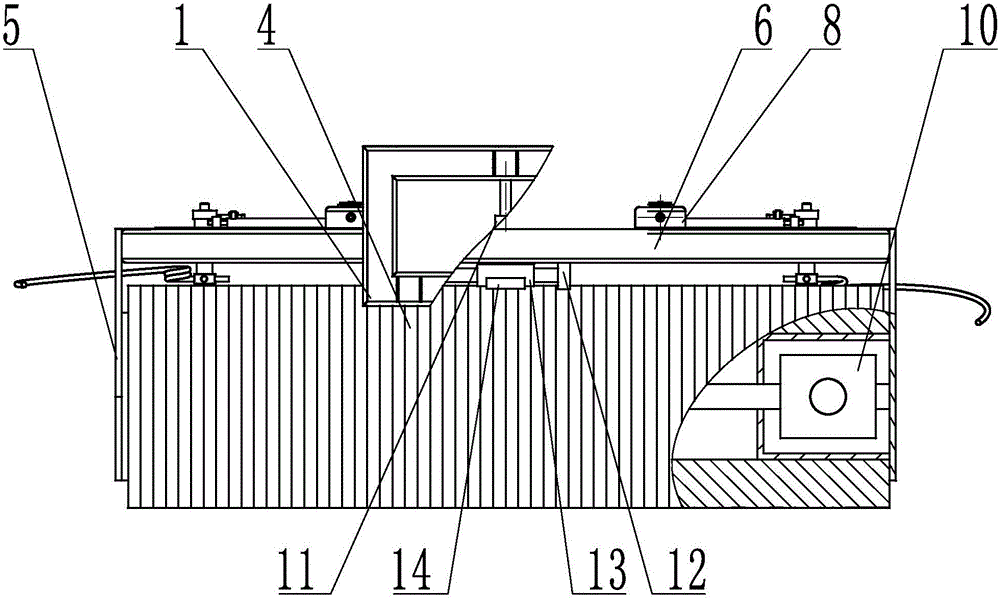

[0033] Embodiment 2: refer to Figure 6-8 It is a structural schematic diagram of Embodiment 2 of the present invention. Compared with Embodiment 1, this embodiment differs in that: the chute mechanism between the fixed frame 1 and the mobile frame 6 is a parallel four-bar mechanism 31 .

[0034] In actual use: the hydraulic oil then enters the traverse cylinder 13, that is, enters a cavity of the double-acting double-piston rod hydraulic cylinder or the single-acting plunger cylinder, and the piston rod on one side shrinks, so that the parallel four-bar mechanism 31 performs reverse deflection, Thereby drive the mobile frame 6 pinned with it to move laterally, to reach the purpose of avoiding obstacles.

Embodiment 3

[0035] Embodiment 3: refer to Figure 9 It is a structural schematic diagram of Embodiment 3 of the present invention. Compared with Embodiment 1 or Embodiment 2, this embodiment differs in that: the driving device 10 of the snow-plowing roller assembly is a hydraulic motor, and the snow-plowing roller assembly The driving device 10 can be arranged in the snow-plowing roller assembly 4 or on the frame 6 , and is connected with the snow-plowing roller assembly 4 through a transmission chain 15 .

[0036] In actual use: different installation positions of the driving device 10 of the snow-plowing roller assembly are selected according to different working conditions, so as to complete the work more efficiently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com