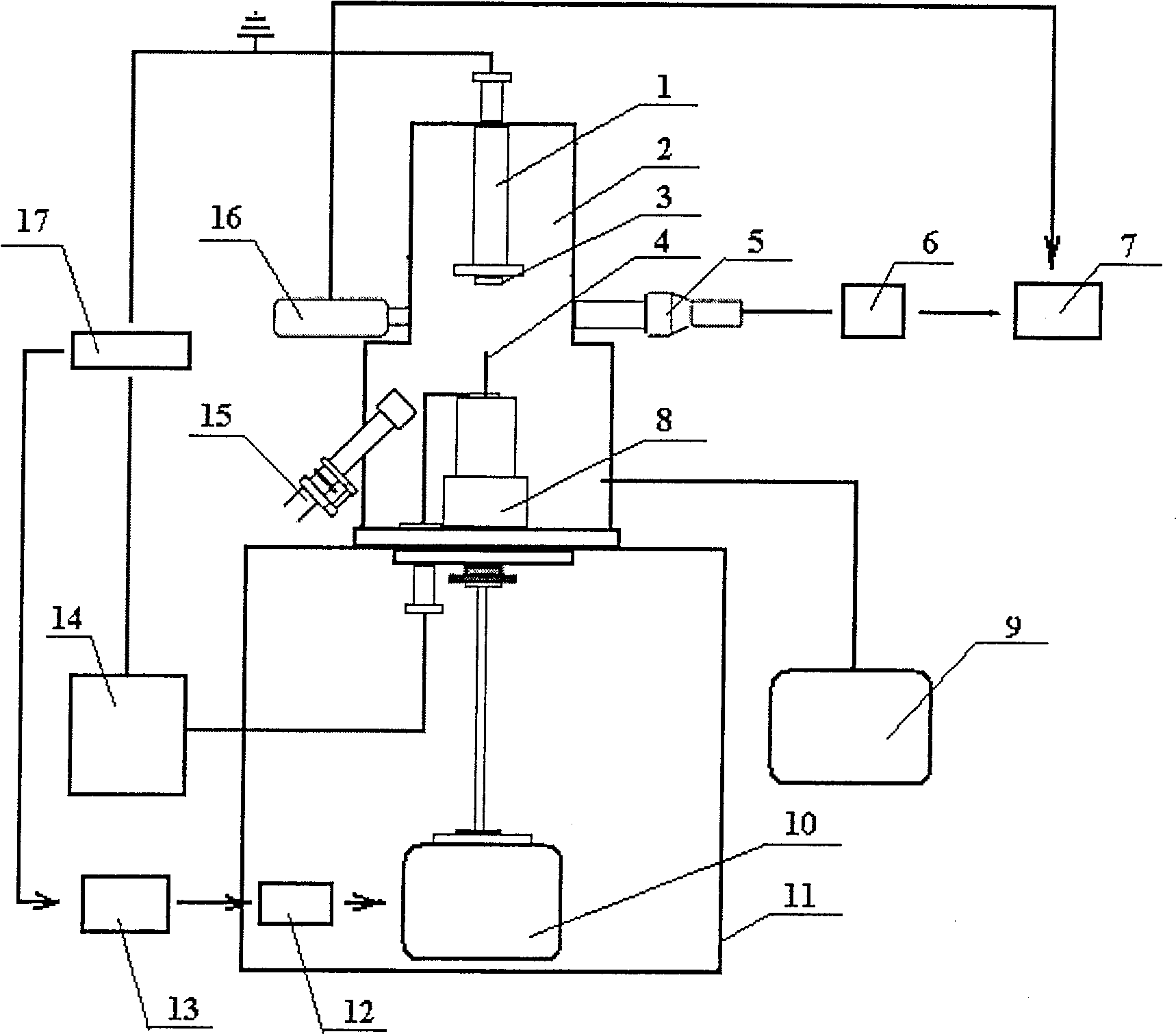

Test apparatus for breakdown strength of material

A technology of breakdown field strength and testing equipment, applied in the direction of testing dielectric strength, etc., can solve the problems of low precision, long time consumption, and not equipped with CCD cameras, etc., to achieve strong data accuracy, high degree of automation, and wide range of applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention measures W-2%ThO 2 The breakdown field strength process of the electrode material is as follows:

[0027] Put W-2% ThO 2 The electrode material is sampled by mechanical processing (such as wire cutting), and then the sample is made into a metallographic sample. After fine polishing, it is placed in a vacuum chamber and fixed on the XYZ three-coordinate support, and the XYZ three-coordinate support is fine-tuned in the three-dimensional space to make the sample plane horizontal And align with the anode. Turn on the vacuum system to keep the vacuum chamber at a high degree of vacuum, the degree of vacuum is not lower than 2×10 -3 Pa. Then start Ar + Gun cleaning system with Ar + Clean the gun for 5 minutes to remove surface impurities and adsorbed gas. Start the DC adjustable power supply, and set the voltage at 8000V as required. Start the hydraulic system power control computer and the CCD camera and range finder control computer. Start the...

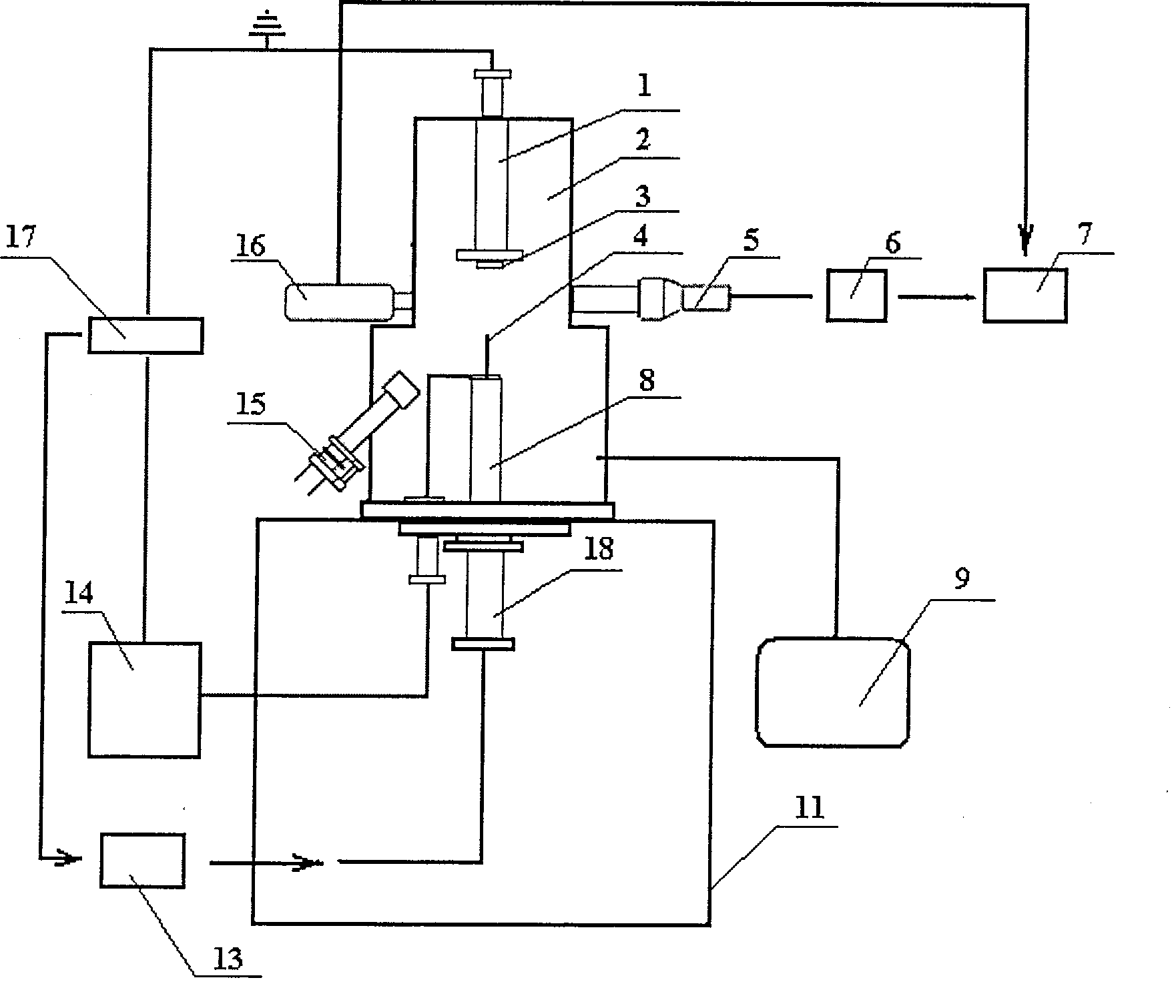

Embodiment 2

[0030] like figure 2 As shown, other structures and testing procedures are the same as those in Example 1, except that the fixed anode device 8 is changed to be connected with a stepping motor + ball screw feeding mechanism 18 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com