Welding torch cable self-rotator

A self-rotation and cable technology, which is applied in the field of welding torch cable self-rotation device, can solve problems such as cable winding and welding torch inoperability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

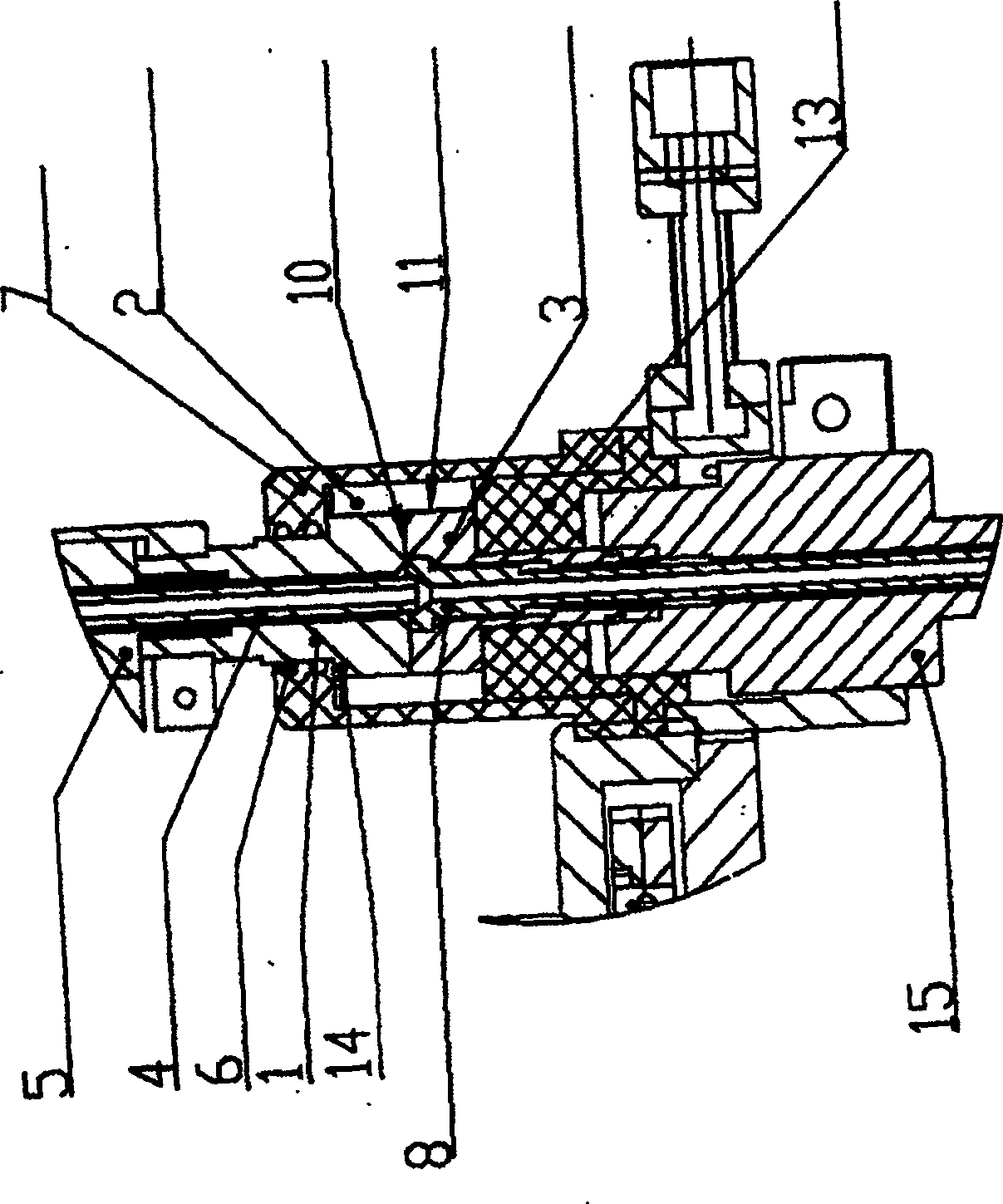

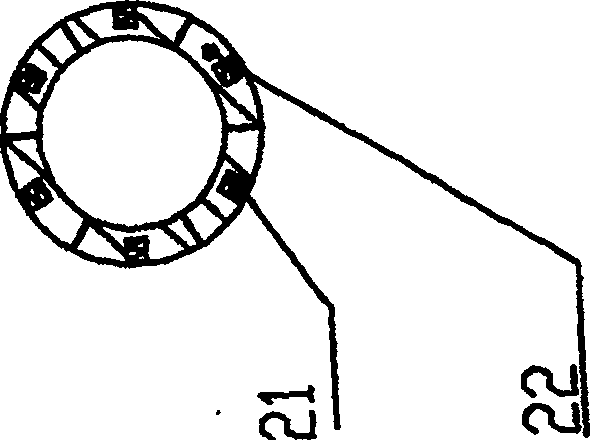

[0017] Control attached figure 1 And attached figure 2 , as further described below:

[0018] A welding torch cable self-revolving device, installed between the tail of the welding torch and the connecting cable, the cable self-revolving device is composed of a rotating body 1, a conductive joint 3 and an elastic conductive ring 2, wherein:

[0019] 1) The upper end of the rotary body is fixed to the cable based on the cable clamp 5 and realizes the conductive connection, and an upper conduction hole is provided in the axial direction to facilitate the extraction of the upper wire feeding hose 4;

[0020] 2) The upper end surface of the conductive joint is in flush contact with the lower end surface of the rotary body to form a flat conductive surface 10. The contact part of the conductive joint and the rotary body has the same circumferential surface, and the lower end of the conductive joint is fixed on the welding torch 15 of the welding torch and To realize the conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com