Structure of jointing and releasing connecting piece

A release piece and connection technology, which is applied to the parts of the connection device, the connection, the coupling device, etc., can solve the problems of the base 104 being easily deformed and the locking piece 103 being difficult to bend, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

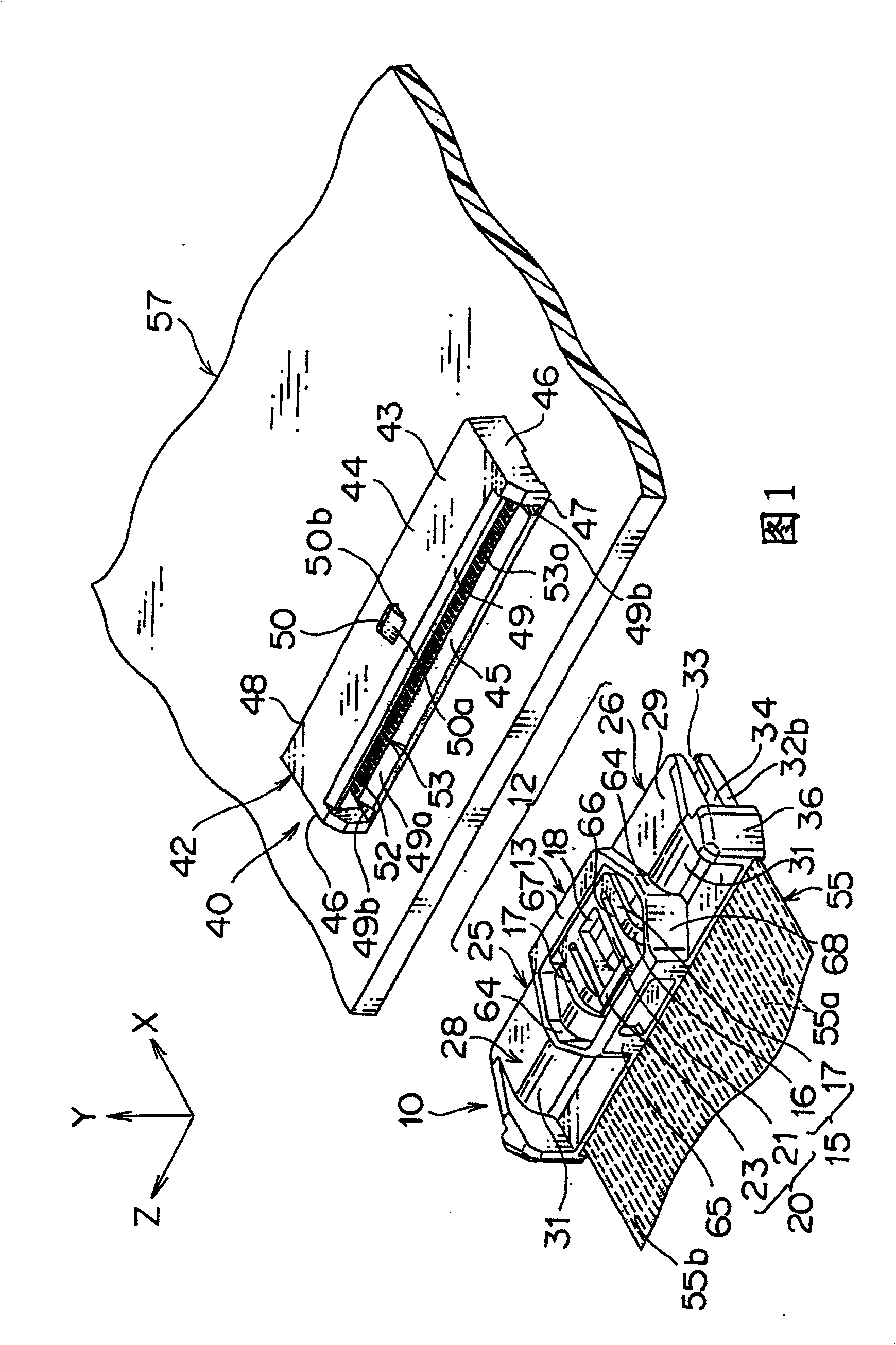

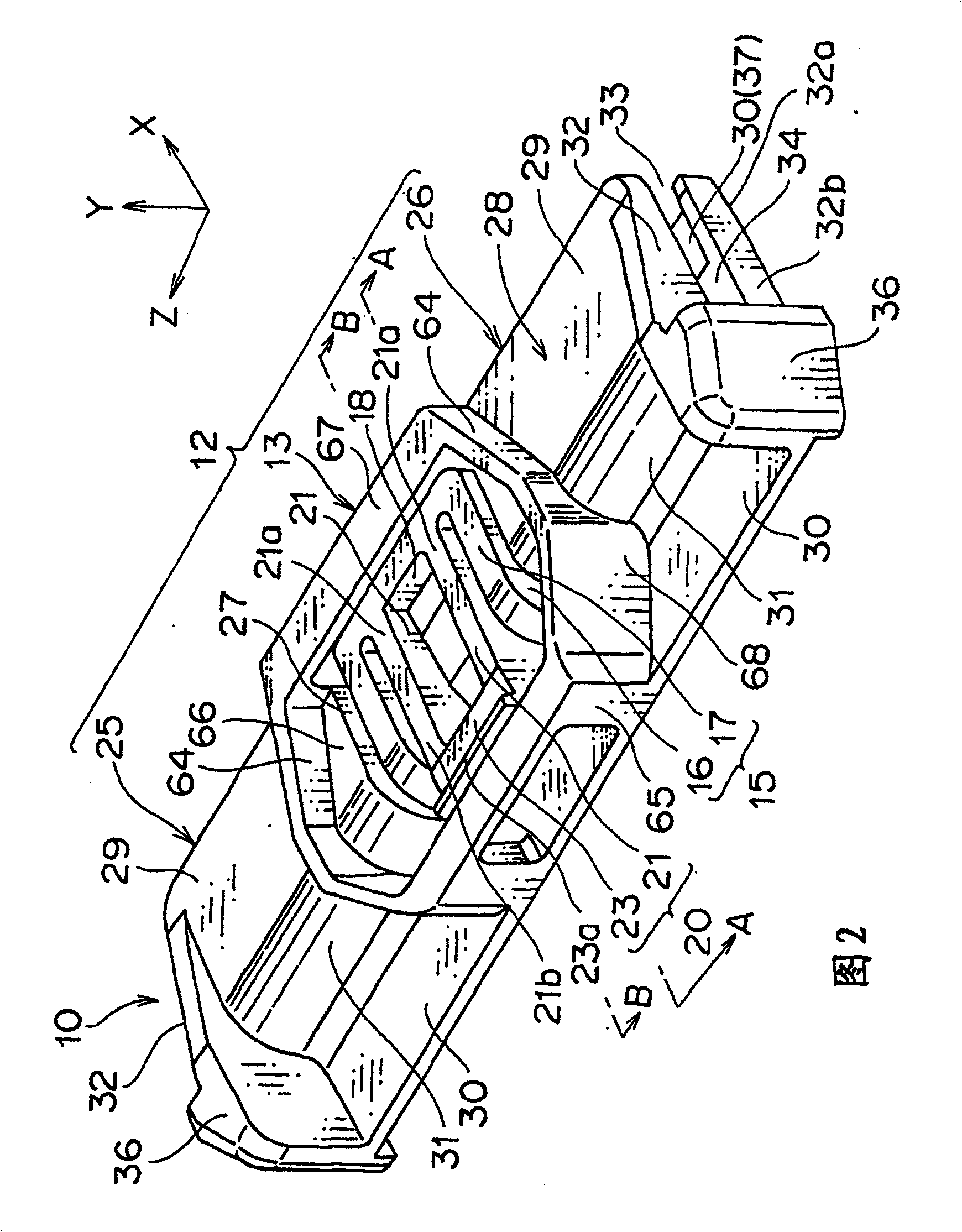

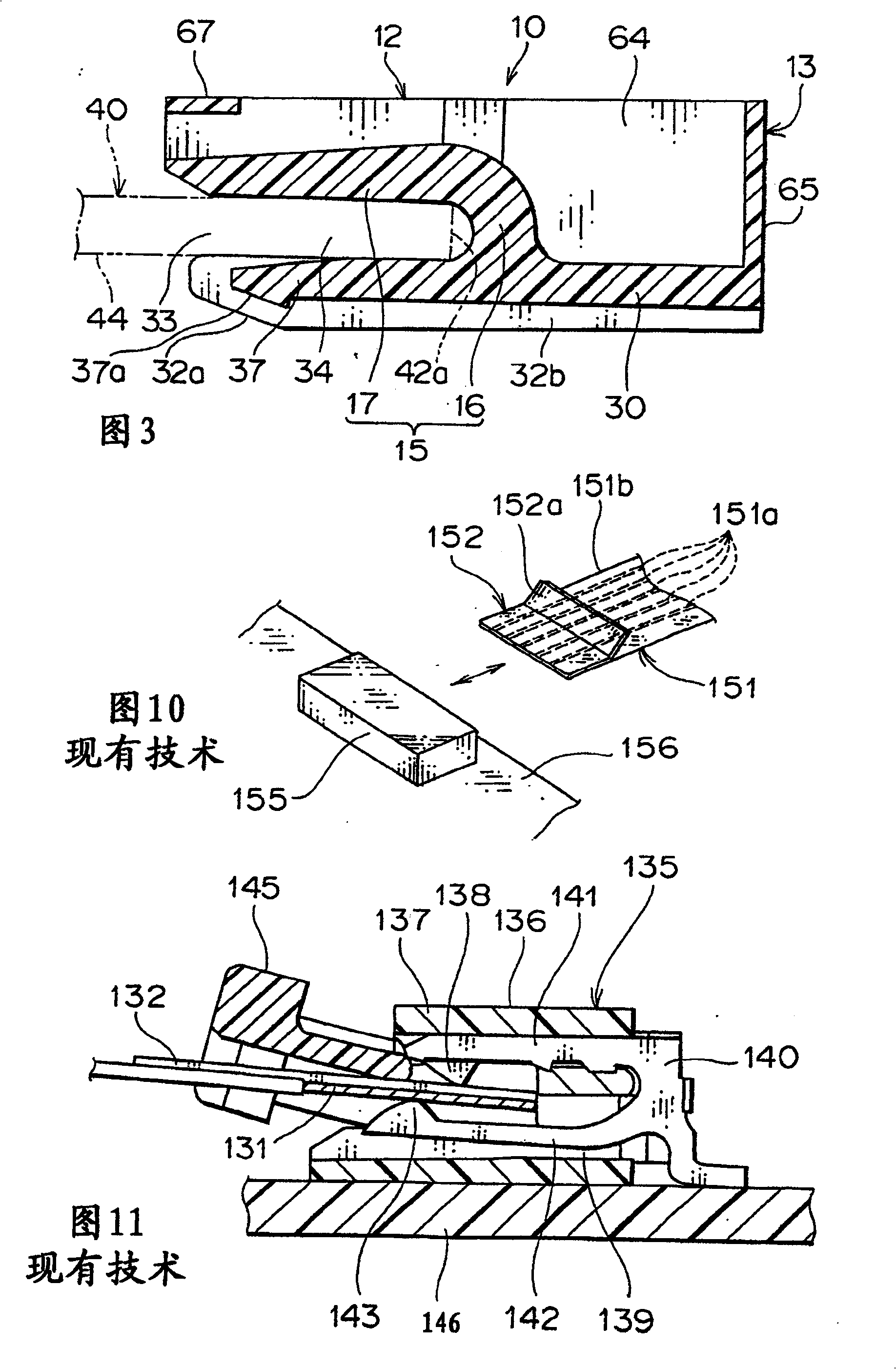

[0064] now refer to Figures 1 to 5 One embodiment of the structure of the connecting shield joint according to the present invention will be described.

[0065] figure 1 Indicates a male connector (second connector) 10, a flexible flat cable (FFC) 55 connected as a flat wire body to the male connector 10, and a female connector (first connector) 40 mounted directly on a printed wiring board ( PCB) 57, as a circuit board.

[0066] The FFC55 is an insulated cable for transmitting a control signal or the like between devices mounted on an automobile, which includes a plurality of conductor bodies 55a arranged in parallel. A covering portion 55b for covering the wire body 55a is an insulating layer made of synthetic resin including polyvinyl chloride resin, polyethylene resin and the like. Several lead bodies correspond to several terminals 53 accommodated in the female fitting 40 .

[0067] In addition, a flexible printed wiring board (FPC, not shown) can also be used as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com