Jet device for producing water atomized spherical metal powder

A metal powder and spraying device technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of low concentricity, non-focusing, and high requirements, and achieve the effects of easy loading and unloading, simplified process, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

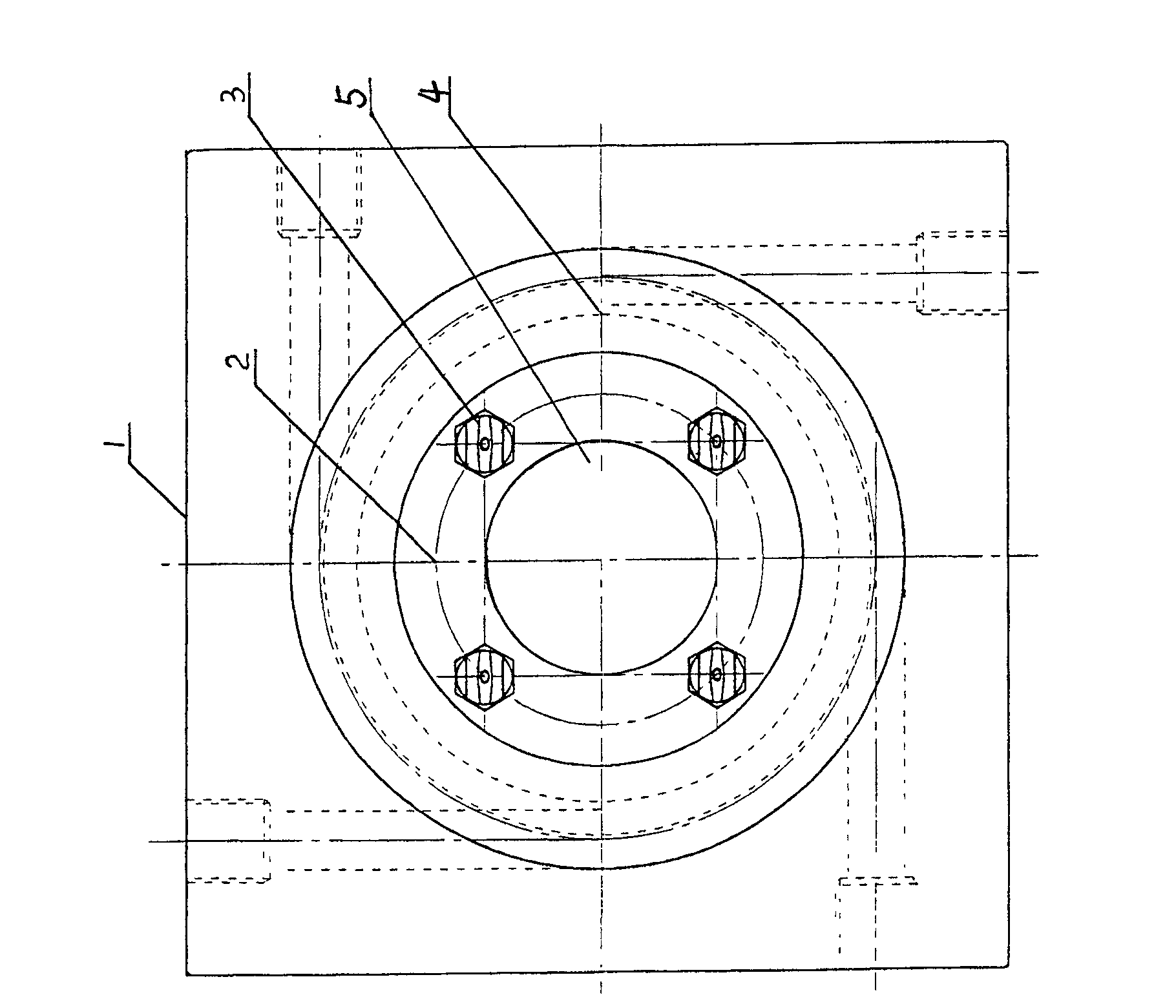

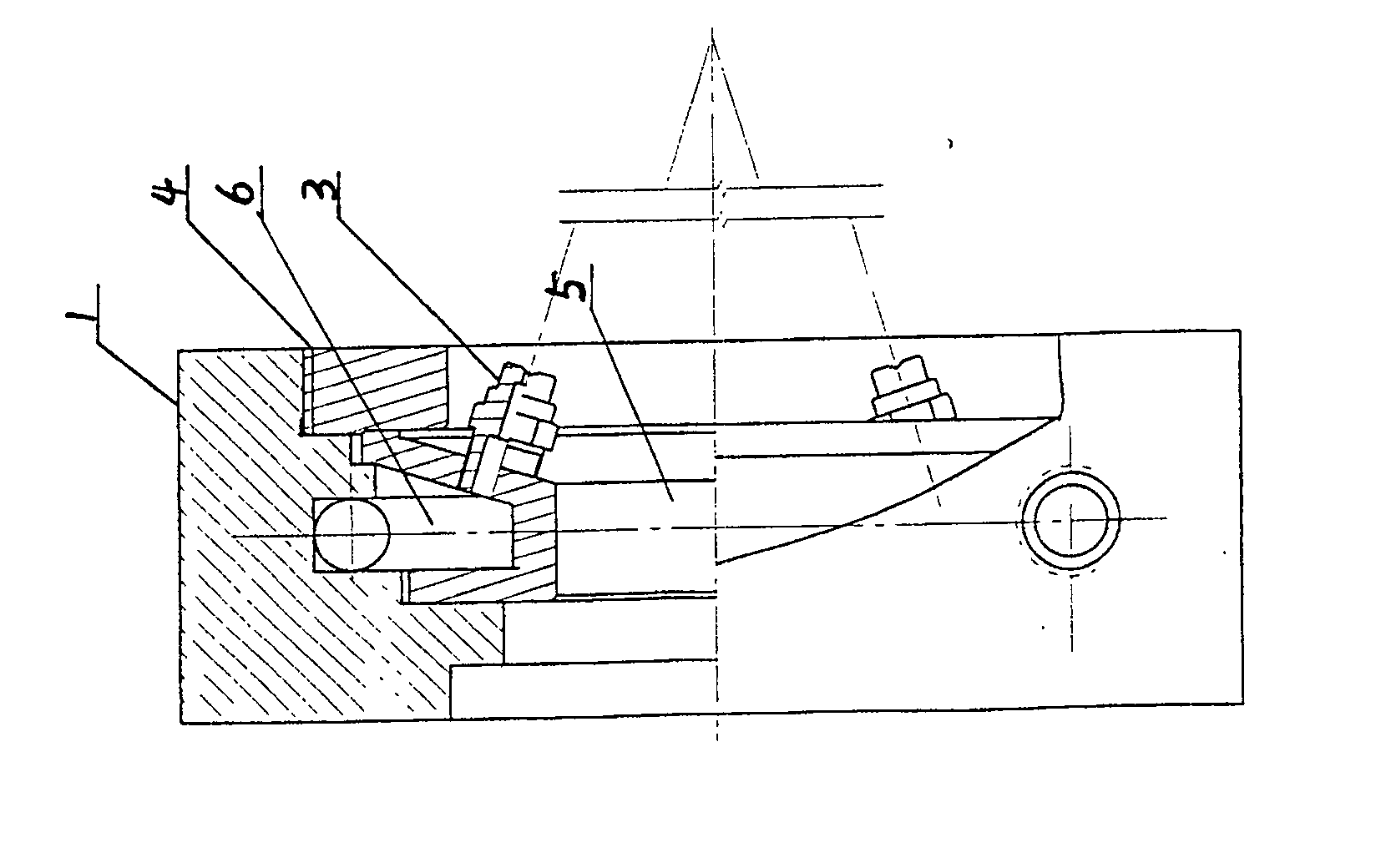

[0024] The injection device for the production of water atomized global metal powder, including the nozzle support 1, the nozzle body 2 and the fastening nut 4, the nozzle body 2 is fixed and installed on the nozzle support 1 through the fastening nut 4; the axial middle of the nozzle body 2 It is a metal liquid flow hole 5, one end is a liquid flow inlet, and the other end is a trumpet-shaped outlet, and a water spray port is opened on the trumpet-shaped ring wall; the cavity between the outer periphery of the nozzle body 2 and the nozzle support 1 is a water channel 6, See figure 1 , figure 2 .

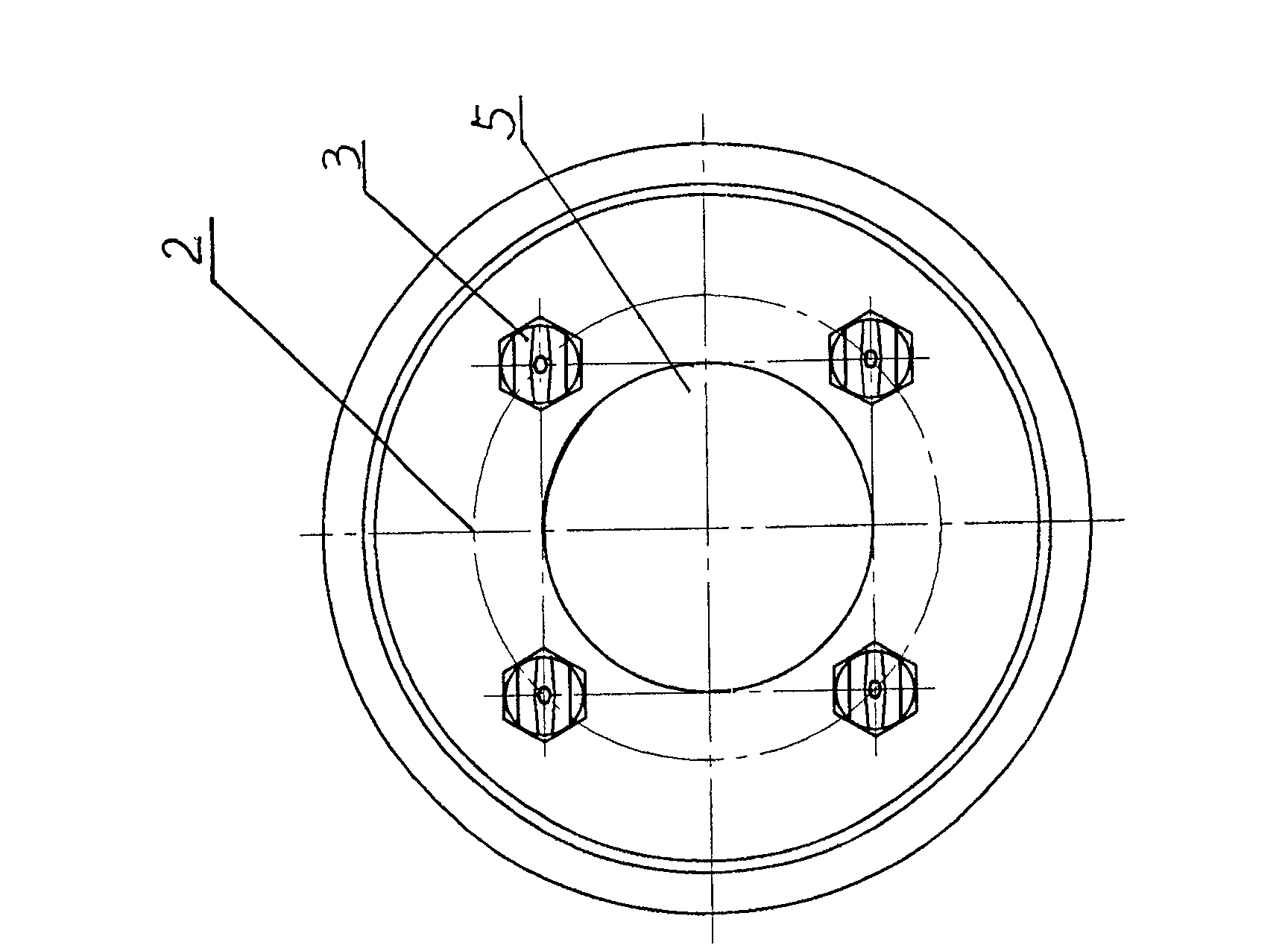

[0025] There are 4 water spouts on the trumpet-shaped ring wall of the nozzle body 2, and a water spout 3 is respectively installed in each water spout, and the water spout 3 extends outside the trumpet-shaped end face of the nozzle body, see image 3 , Figure 4 ;Adopt threaded connection between the sprinkler head 3 and the nozzle body on the sprinkler body, which is convenien...

Embodiment 2

[0029] There are 8 water spouts on the trumpet-shaped ring wall of the nozzle body, and a water spout 3 is respectively installed in each spout, and the water spout 3 extends outside the trumpet-shaped end surface of the sprinkler body.

[0030] The spray hole orifice of water sprinkler head is oval hole, and the major axis length of its spray hole orifice is 3 millimeters, and the minor axis length is 1.5 millimeter, and the major axis of the spray hole of 8 sprinkler heads is vertically parallel.

[0031] Other structures are with embodiment 1.

Embodiment 3

[0033] There are 6 water spouts on the trumpet-shaped ring wall of the nozzle body, and a water spout 3 is respectively installed in each spout, and the water spout extends outside the trumpet-shaped end face of the nozzle body.

[0034] The spray hole orifice of the sprinkler head is an oval hole, the major axis length of the spray hole orifice is 2 millimeters, and the minor axis length is 1 millimeter, and the major axes of the spray holes of the 6 sprinkler heads are horizontally parallel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com